I’ve seen many people compare laser engraving machines to find the right fit for their business. When deciding between Maxwave and Coherent, I suggest you look beyond just the price and technical sheets.

From my experience, it’s more about how the machine fits your workflow. You should think about energy efficiency, precision needs, and overall running costs. Each brand has its strong points. I’ve noticed, however, that there is one key factor that most new buyers miss. It’s an important detail they should consider.

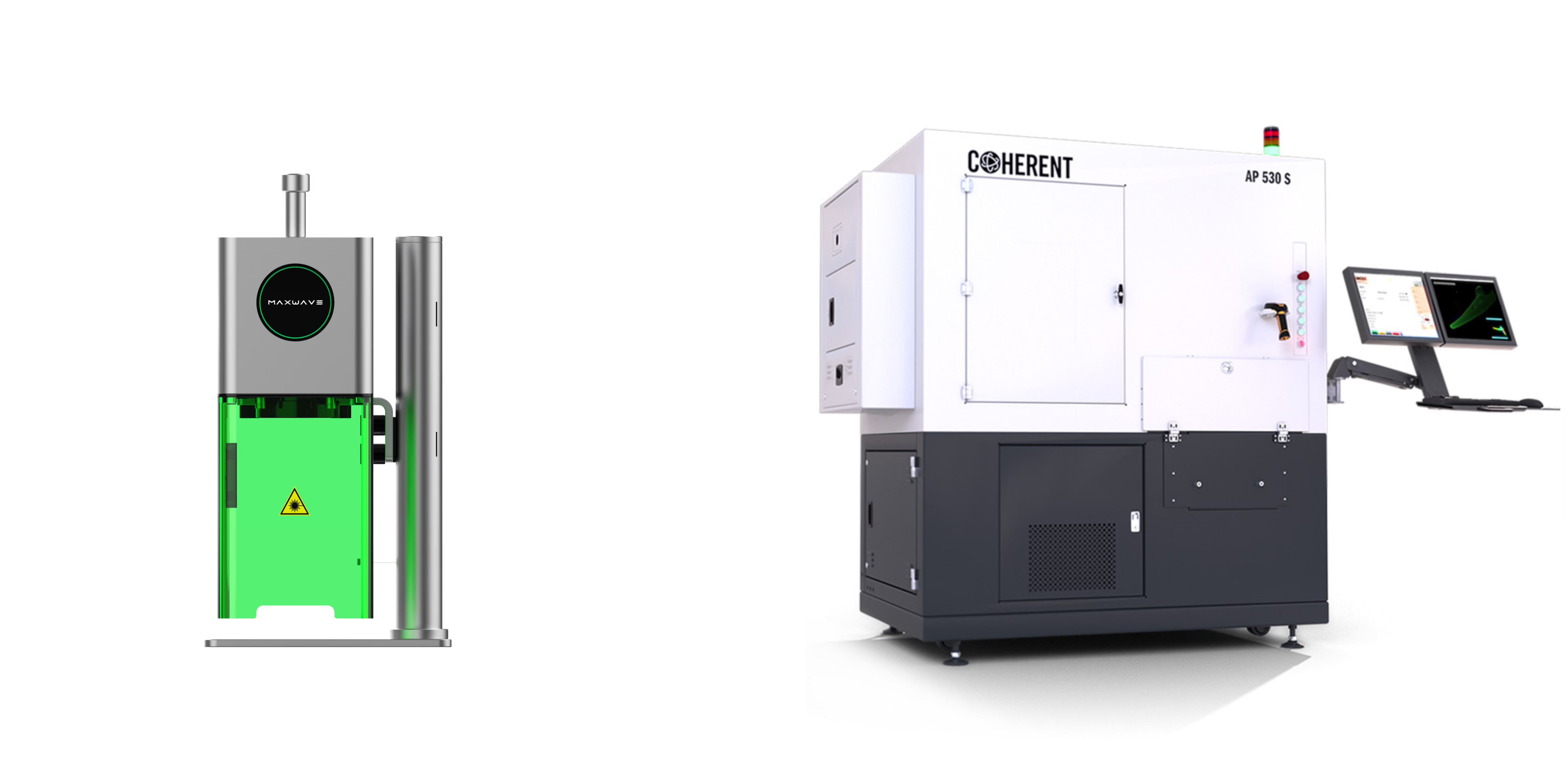

A Look at Maxwave and Coherent Laser Engraving Machines

From my experience, Maxwave and Coherent are top brands for laser engraving machines. I see that each one has its own strength for industry and manufacturing work. Let’s examine their technical details and how they can be used. I will focus on important factors like marking accuracy, power efficiency, the materials they work with, and their fiber laser systems.

| Comparison | Maxwave | Coherent |

|---|---|---|

| Value | High energy efficiency (95%); low running cost; dual-laser marking models are affordable and easy to maintain | Higher initial cost, but saves labor; ideal for high-precision tasks |

| Performance | Power range 2W–200W; options from compact to high-power deep engraving; suitable for small to large jobs | Accurate (±0.01 mm), fast (up to 7000 mm/s); excels in precision marking |

| Applications | Textiles, apparel, large metal or non-metal parts; versatile and energy-saving | Production lines, small-batch high-precision work; optimized for quick integration |

| Flexibility | Ultra-light model available, only 3.9 kg; supports multiple work areas and rotary attachments | Easily integrated into existing production lines; compatible with multiple file formats |

| Overall Value | Best for energy-conscious, flexible, multi-application use | Best for high-precision, fast deployment, and production efficiency |

Marking Speed and Precision: Maxwave vs Coherent Laser Engraving Machine

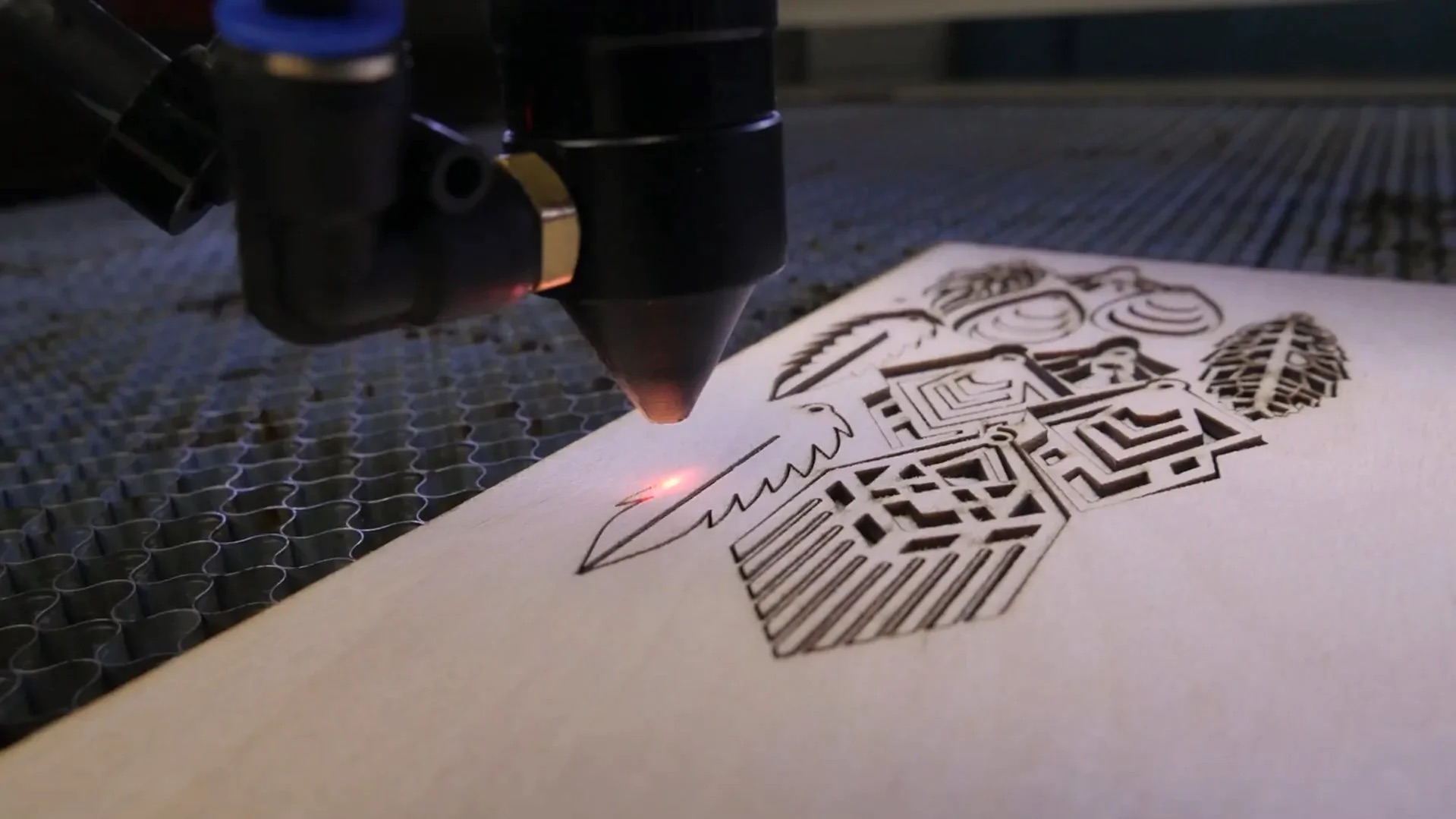

When I help people choose a laser engraving machine, two things matter most: marking speed and precision. These are vital for any business that values efficiency and needs a permanent way to track products.

Maxwave: High Precision and Speed with Flexible Automation

Maxwave laser Engraving machines are known for combining precision, speed, and versatility in industrial and on-site applications. The MW-F25CA is an ultra-light, dual-laser unit that can be used as both a desktop and handheld system. Equipped with auto-focus, a rotary axis, and a sliding worktable, it delivers fast, positioning speeds up to 10,000 mm/s with ±0.01 mm repeatability. Perfect for metals, plastics, composites, and glass, it efficiently handles serial numbers and tracking on electronics, automotive parts, and medical devices. Its lightweight design and Bluetooth remote control make batch and on-site marking seamless and accurate.

Coherent: High-Volume Batch Precision with Advanced Automation

In my view, Coherent excels in automation, enabling high-volume, unattended precision marking with minimal operator involvement. The ExactMark 210 TL impressed me with its automatic tray loading, handling up to 30 trays at once, making it ideal for electronics, automotive, and aerospace industries with strict quality standards. It ensures consistent, precise marks across all parts in a batch without sacrificing speed or quality. I recommend it for operations that require fast, reliable output, and its batch capabilities are especially valuable for serialization and compliance in regulated industries.

Comparative Advantages

- Maxwave: I recommend Maxwave for projects that need portability, specific automation, and high-precision mobile or batch work. Its flexible controls are a big plus.

- Coherent: I suggest Coherent for automated, high-volume production lines. It’s the best choice if you need the machine to run on its own with consistency.

Both brands meet tough industrial standards for clear marks, reliability, and working with different materials. Based on my experience, they just serve different needs. One is for flexible precision, and the other is for factory-scale efficiency.

A Look at Lifespan: Maxwave vs. Coherent Laser Engravers

From my experience, a laser Engraver’s lifespan and reliability have a huge impact on your costs and production. These factors determine the machine’s real value over time. I’ll compare Maxwave and Coherent on these key points.

Maxwave: Long Lifespan, Low Maintenance

I’ve found that Maxwave laser engraver are highly durable, lasting up to 100,000 hours—far longer than the typical 10,000–30,000 hours of most fiber lasers—thanks to quality Raycus laser sources. They operate without consumables and feature a robust air-cooled system, reducing wear and eliminating cool-down delays. CE and ISO certifications reflect their high quality and safety standards. With a 1–2 year warranty and responsive technical support, these machines are reliable in continuous production, and their maintenance-free design helps save costs over the long term.

Coherent: Reliable Performance, Standard Lifespan

Coherent machines are reliable and precise, with fiber or CO₂ laser sources lasting 10,000–30,000 hours. Their CO₂ models require gas refills, adding extra costs and downtime, while Maxwave fiber lasers are maintenance-free. Coherent excels at consistent marking across parts, but routine maintenance and part replacements can increase total ownership costs for high-use environments.

Key Differences I See

- Maxwave: What I like most is its incredibly long lifespan and maintenance-free design. The air cooling, Raycus laser, and lack of consumables all lead to less downtime and cheaper operation.

- Coherent: This brand offers dependable performance I can trust. But, I think you need to balance its standard lifespan and need for new parts against the value you get from a heavy-duty machine like Maxwave.

Based on my experience, if your top goals are uptime and low ownership costs, I recommend Maxwave. Its 100,000-hour lifespan is a major advantage. The air-cooled design and no-consumables approach make it, in my opinion, the best choice for busy production lines that run 24/7. Coherent is a solid option for high-precision jobs, but be prepared for more maintenance throughout its life.

Software Compatibility and Ease of Use

I believe two things are critical when you choose a laser engraving solution. First, how well its software fits your design process. Second, how easy it is for operators of any skill level to use. From my perspective, this defines much of the value you get from either a MaxWave or a Coherent system.

MaxWave: High Compatibility for a Smooth Workflow

Based on my experience, MaxWave machines have great compatibility. They work directly with common design software and many file formats. I find this helps you cut down on extra steps and get work done faster.

- Works with the tools you already use: I like that you can send designs from CorelDraw, AutoCAD, or Photoshop. You don’t need to convert files, which saves a lot of time and prevents mistakes.

- Supports many file types: It handles PLT, DXF, AI, DST, BMP, JPG, SHX, and TTF files. This gives you flexibility for both vector and raster images, plus different industrial fonts.

- Easy-to-use, customizable interface: I find the Windows-based interface simple and flexible. It runs on Windows XP, Vista, 7, or 10, so the environment feels familiar.

- Powerful automation tools: The software comes with built-in automation. It can handle automatic coding, serial numbers, and batch numbers. You can also mark dates and barcodes, even QR codes. All of this is done inside the software without needing separate scripts.

- Adaptable interface design: You can change the interface to fit your industry or specific jobs. I think this helps operators find the right controls quickly and cuts down on training.

Coherent: Custom Interfaces and Industrial Network Control

Coherent often partners with software companies like MECCO. They provide powerful, Windows-based control systems. I’ve found they specialize in two main areas: custom-built user interfaces and connecting multiple machines over a network.

- Custom interfaces: Coherent doesn’t connect with design tools as easily as MaxWave. Instead, its Visual BASIC.NET interfaces can be built for a specific industrial process or how an operator works.

- Good for networking: You can control multiple laser systems from a single computer. I see this as a huge benefit for large production lines that require batch control and reports.

- A typical industry example: I know in the aerospace field, Coherent’s software has replaced older, inefficient systems. It let operators manage several machines with one interface. This improved speed and consistency, but in my opinion, it often requires special IT help to get set up.

My final take is this: MaxWave gives you a plug-and-play experience. I find it is efficient for most production and design teams. On the other hand, Coherent provides deep customization and batch management for big industrial settings. Both run on Windows. However, I believe the easy and broad software support of MaxWave gives it an advantage for most people who need a flexible and fast solution.

Price, Running Costs, and Maintenance: Maxwave vs. Coherent Laser Engraver

When I look at laser engraving systems, I focus on three things for good value: purchase price, running costs, and maintenance needs. Let’s see how Maxwave and Coherent stack up.

Price Comparison

Maxwave focuses on providing affordable, high-value laser marking solutions. In my experience, their dual-laser machines start at just $1,200, while entry-level handheld semiconductor models are even more accessible at $750, making them perfect for startups and small studios. By comparison, Coherent machines with similar features are much more expensive, typically ranging from $5,000 to $15,000—several times the cost of Maxwave units.

Running costs

Maxwave Dual-Laser Engraving Machines: They have very low operating costs thanks to the affordable glass laser tubes. The 10W+2W models consume ≤90W, making them highly efficient and helping reduce electricity expenses.

Coherent Machines: These are designed for industrial use and feature energy-saving smart designs. However, replacement parts and service costs are higher. While their engineered laser sources have a very long lifespan, maintenance or replacement typically requires authorized technicians, which increases the total ownership cost.

Maintenance Requirements

Maxwave Laser Systems: These machines are almost maintenance-free. You mostly just need to remove dust and do a quick check of the optics once in a while. They have no consumables, so you don’t need to buy replacement tubes.

Coherent Laser Engraving Systems: These are built for heavy use. They come with smart features like predicting when maintenance is needed and remote problem-solving. They also offer tech support around the world. I suggest planning for scheduled visits from a technician. These visits can be more expensive than maintaining a Maxwave machine yourself. The features are advanced, but you should know the total service costs over a few years can be high.

If your budget is the most important factor and you like doing your own maintenance, I suggest Maxwave. It gives you great value for your money. If you need a machine to last a long time with maximum uptime and worldwide tech support, Coherent is the answer, but it comes at a higher price.

Summary

Based on my experience, I’ve worked closely with both Maxwave and Coherent. People often ask me which machine is the absolute “best.” In my opinion, it’s more about finding the right machine for your specific work.

I suggest Maxwave if you need an affordable and flexible option. If you need top-tier precision and automation, I’d go with Coherent. Both are great brands and will serve you well. The important thing is to know what your business needs most. From what I’ve seen, the most practical choice usually ends up being the most profitable one. Ready to learn more? Contact us now for expert advice on laser engraving machines.