From life-saving implants to precision surgical tools, modern medical devices demand perfection — and that’s exactly what laser welding delivers. As the healthcare industry pushes the boundaries of innovation, manufacturers are turning to laser welding machines for their unmatched precision, cleanliness, and reliability.

Whether it’s bonding tiny titanium components or creating seamless seals on stainless steel instruments, laser welding is revolutionizing how medical devices are made — enabling safer procedures, smaller incisions, and faster patient recovery. In this article, we explore how this cutting-edge technology is reshaping the future of medical manufacturing.

A Look at Medical Device Manufacturing With Laser Welding Machines

I find that laser welding machines are really changing how medical devices are made. They bring better precision, more efficiency, and new ideas to the field. By 2025, the worldwide market for these machines is worth $500 million. I expect it to grow by 7% each year, hitting around $850 million by 2033. What’s driving this growth? I believe it’s the need for surgical methods that are less invasive and the wider use of new laser tech.

Why Laser Welding Matters for Medical Devices

It offers extremely high precision and the ability to weld very small components, which is crucial for the complex and delicate parts used in medical devices. The heat-affected zone is minimal, reducing the risk of damaging sensitive materials and ensuring the safety and performance of the device.

Laser welding machine also creates strong, airtight joints—critical for maintaining sterility and durability in medical environments. Additionally, the process is highly automated, providing excellent efficiency and consistency, which meets the strict quality standards of the medical industry. For these reasons, laser welding has become an indispensable technology in the production of medical devices.

What I See in Market Trends and Key Companies

Looking at all uses, surgical devices make up the biggest part of the laser welding market for medical devices. Implants and dental devices follow right after. I notice that universal laser welding machines are popular. This is because they can adjust to many materials and device designs. Big companies like IPG Photonics, Amada Miyachi, and MaxWave are pushing innovation forward. They do this with new solutions and by operating worldwide, which I think is impressive.

Understanding Laser Welding for Medical Devices

In my view, laser welding for medical devices demands precision and accuracy. We also need to ensure top safety and reliability. and how the laser welding machine makes it possible::

Core Process Characteristics

Focused Melting: The laser produces high energy at a very small point. This creates a small, controlled pool of melted material. From my experience, it hardens fast. It does not affect the nearby areas.

Creating the Seam: As the weld moves forward, the front edge melts. The back edge cools down. This process creates a smooth, unbroken seam. It has little heat impact on the material next to it.

Preventing Oxidation: We precisely control parameters and use shielding gases. This helps us make welds without oxidation. I believe this is crucial for medical-grade quality.

Types of Laser Welding in Medical Devices

Macro-Scale Seam Sealing: We use this for ongoing, larger joints. These joints must be airtight or prevent leaks.

Micro-Spot Welding: This is great for joining small, sensitive electronic parts or structural pieces. These require very precise work.

Advantages of Laser Welding in Medical Device Manufacturing

I find that laser welding machine brings unique benefits, making it vital for today’s medical device making. Let me show you why it’s a top choice:

Unmatched Precision and Material Compatibility

From my perspective, laser welding machine creates very precise connections. This is crucial for putting together complex items such as catheters, stents, and surgical tools. I’ve seen it bond different materials like metals, plastics, and ceramics. This opens up many design options. It also helps create new devices with complex shapes.

Repeatability, Process Stability, and Enhanced Cleanliness

I find laser welding gives consistent and dependable results. Electrodes don’t wear out or cause contamination. So, the weld quality stays the same. The process is also very clean. You don’t need fluxes or solvents. The weld seams are smooth. This smoothness makes them easy to sterilize, which I think is vital for medical uses.

Speed, Efficiency, and High-Volume Adaptability

Based on my experience, laser welding works four to five times faster than older methods like TIG or MIG. This leads to quicker production times. It also lowers total manufacturing costs. I suggest this technique for both small and large production runs. It helps factories meet the rising demand for medical devices.

Cost Savings Over Time

The first cost for laser welding machine gear might seem high. But, in my opinion, you’ll see savings over time. You get faster work cycles and dependable results. There’s less need to redo work. You also have less finishing work. All these things help cut costs as you make more products.

Market Growth and Proven Applications

The world market for laser welding was $1.96 billion in 2021. It’s expected to hit $2.79 billion by 2029. I see this growth is mainly due to more use in medical fields. You can see it used in items like microfluidic devices, catheters, implants, and surgical tools. It’s also used for sealed electronic devices. This shows me that laser welding is basic to making healthcare products and helps patients do better.

Laser Welding Machines Are Changing Medical Device Manufacturing

According to the latest market research, the global laser welding equipment market is expected to reach approximately $3.1 billion in 2025, showing steady growth from 2024 with a compound annual growth rate (CAGR) of 5.6%. Among the segments, fiber laser welding machines are projected to account for around $1.58 billion, driven by their high efficiency and low maintenance costs, making them ideal for medical device and electronics manufacturing. The demand from the medical device industry is becoming a key driver of market expansion. Overall, the laser welding market is expected to continue growing, supported by increasing adoption in the automotive, electronics, and medical sectors.

Key Growth Drivers I See in Medical Device Manufacturing

Aging Population and Chronic Disease Management Demand: – Rising Aging Demographics: The global population aged 65 and above continues to grow (e.g., China’s elderly will exceed 30% by 2035), driving demand for orthopedic implants, cardiovascular stents, and glucose monitoring devices. – Chronic Disease Epidemic: Conditions like diabetes and hypertension require long-term monitoring and treatment devices (e.g., portable ventilators, insulin pumps), fueling the home healthcare market.

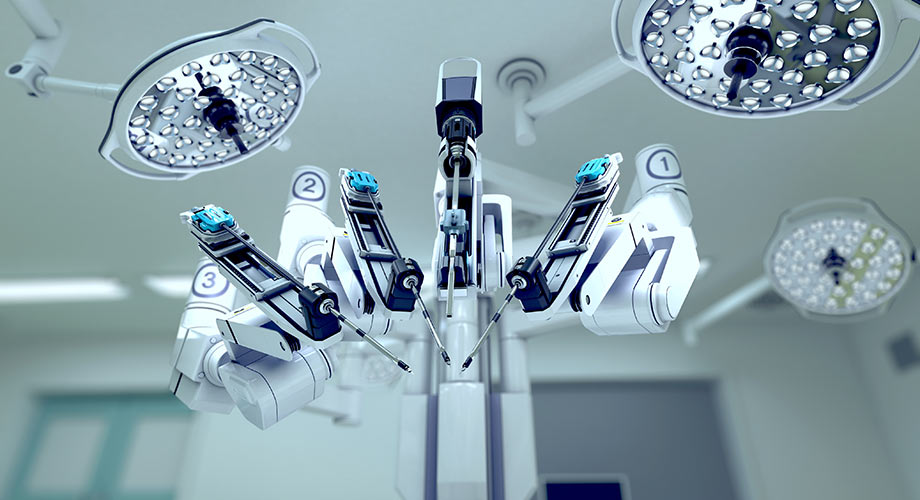

Medical Technology Innovation: – Smart and Digital Solutions: AI-assisted diagnostics (e.g., AI-based imaging analysis), wearable devices (e.g., ECG smartwatches), and remote monitoring technologies (e.g., IoT-connected blood pressure monitors) enhance healthcare efficiency. – Minimally Invasive and Precision Medicine: Surgical robots (e.g., da Vinci System), high-value consumables (e.g., bioresorbable stents), and genetic testing devices drive industry advancements. – Advanced Material Applications: 3D-printed customized prosthetics and nano-coatings improve implant performance.

To sum up, I believe the future for making medical devices with laser welding machines looks bright. We’ll see ongoing market growth. Technology will continue to blend in. More places around the world will use it. This makes laser welding a key part of new, top-quality healthcare solutions.

Summary

In a world where precision saves lives, investing in the right technology isn’t just a choice — it’s a responsibility. Laser welding machines empower medical device manufacturers to meet the highest standards of safety, accuracy, and efficiency. Whether you’re scaling production, improving product quality, or innovating new designs, now is the time to embrace a solution that delivers unmatched results. Discover how our advanced laser welding systems can transform your medical manufacturing process — and give your business the competitive edge it deserves.

Recent Comments