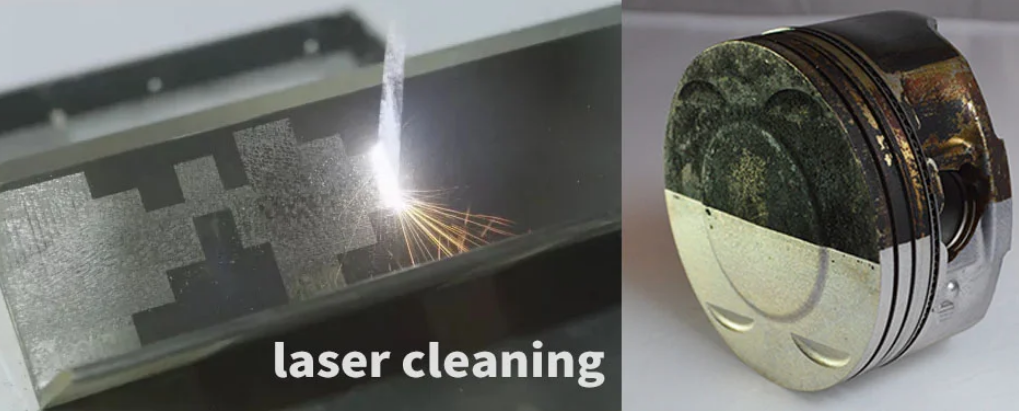

I think laser cleaning systems might really surprise you. They are great if you want to clean tough messes and also want to help our planet. I often wondered: do environment-friendly choices mean less power or more hassle? Maybe you’ve thought this too. From what I’ve seen, these systems can be game-changers. This applies whether you need to move them around different job sites. It also applies to demanding factory tasks. But based on my experience, there’s one key thing people often forget before they choose…

Where to Use Portable and Stationary Laser Cleaners

Many industries use laser cleaning machines. I find that choosing between portable and stationary setups really depends on your specific tasks. Let me show you where each type excels and give some practical examples of how people use them.

Portable Laser Cleaning Applications

I’d recommend portable laser cleaning systems when you need to move around easily and adapt to different spots. You’ll often find them used for:

- Field maintenance: You can clean large structures or machines right at the job site. For example, removing small rust spots on construction gear, bridges, or train tracks.

- Restoration projects: These systems clean sculptures, statues, or old buildings with precision. I like that they don’t cause damage because they are small and easy to control.

- Graffiti removal and paint stripping: They are great for quick cleaning of metal, signs, or public structures while you’re on the move.

- Pipeline and tank cleaning: In the oil and gas field, these portable lasers can reach far-off or tight spaces. I’ve seen them used to remove specific areas of corrosion and scale.

- Aircraft and vehicle touch-ups: Mobile teams can use a 100W portable fiber laser. These units weigh just 15–35kg. They remove adhesives, sealants, or dirt from aircraft parts or car frames right where they are.

Stationary Laser Cleaning Applications

I suggest stationary (enclosed or compact) laser cleaning machines when you need automation, consistent results, and safe operation above all. Here are common ways I see them used:

- Automotive production lines: Powerful stationary systems (often 1000–2000W+) are built into these lines for non-stop cleaning. They strip paint, remove rust, or prepare large metal panels before parts are put together. This requires very little manual work.

- Industrial manufacturing and shipyards: These systems handle big jobs like cleaning ship hulls, removing paint, or maintaining molds. Automated alignment and part feeding help get more done and improve safety, which I think is a big plus.

- Aerospace component cleaning: They are used for repetitive, very precise jobs. For instance, a 2000W stationary water-cooled system can remove oxides from standard parts. This ensures consistent results and safety.

- Electronics or metalworking: These systems remove tiny bits of residue, oxides, or unwanted coatings. The parts usually move on conveyors or through robotic workstations.

How to Choose:

To pick the right system, I suggest you think about a few things: the size and shape of the parts, how thick and what type of dirt you’re dealing with, the cleaning speed you need, workplace safety and available space, and if the jobs are the same or change often. If you need to be precise, work hands-on, and move around, a portable unit is probably your best bet in my opinion. For cleaning many items at once or for automated production lines, I believe a stationary system will give you better efficiency and let you process more items.

Key Differences: Portable vs Stationary Laser Cleaning Systems

Portable and stationary laser cleaning machines have some key differences. I’m here to break them down. This should help you choose what’s best for what you need.

Power and Performance

From my experience, portable laser cleaners offer power from 100W to 200W. A 100W fiber laser system is a common choice for mobile teams and job sites. Stationary laser cleaning systems provide much higher power. They often deliver 1000W–2000W or more. I find these are great for tough industrial jobs. For instance, a 2000W water-cooled unit works well on an assembly line.

Mobility and Flexibility

Portable units are light, small, and simple to move. You can take the equipment right to big or tricky workpieces. I think this is perfect for field upkeep, on-location fixes, or cleaning in spots that are hard to reach. Stationary systems stay in one specific place. People design them for regular cleaning of parts or items that do not have complicated shapes.

Application Suitability

I recommend portable systems for jobs with often-changing parts or odd shapes. They adapt well to tasks like taking rust off building gear or cleaning inside tanks. Restoring sculptures is another good use. Stationary systems shine where you need automation, steady results, and fast work. Think automotive manufacturing lines or shipyard cleaning of many items. They are good for many similar jobs on regular surfaces.

Investment and Operating Costs

Portable laser cleaning machines often have a lower starting price. They also need little setup. Based on my experience, this is a significant advantage for many. Stationary solutions need a bigger initial investment. You might need more space for installation. Custom safety areas and linking to production lines could also be part of the setup.

Operation and Ease of Use

Some portable systems use battery power. This gives more freedom, which I find useful for remote jobs. How well they work can depend on the user’s skill and how steady their hand is. You can build stationary lasers into automated production lines. They clean consistently and accurately. This is because you can program their settings.

Summary

If you’re choosing between a portable or a stationary laser cleaner, I think it really depends on what you need it for. Based on my experience, I suggest you first figure out your cleaning tasks. Also, check your workspace limits. What are your long-term goals? I find knowing these points is crucial before you pick.

I like that both types are much better for the environment than old chemical methods. They create less waste. They also get rid of harmful solvents. We all want our industries to be kinder to the earth. I believe these laser tools are a big help for that. In my opinion, the right system for you offers good power, flexibility, and works well. Importantly, it also helps protect our planet. I genuinely think investing in such a system is a smart choice. For more details about laser cleaning machine or to get a quote, contact us today!