For decades, shipyards have depended on abrasive blasting and high-pressure waterjetting. However, the severe costs of these methods are now clear: they endanger worker health with toxic dust and noise, generate hazardous waste and wastewater, and violate environmental regulations.These processes are also highly inefficient, consuming excessive time and operational budget. Tightening global regulations are forcing change.This critical moment presents a transformative opportunity. Laser cleaning technology offers a precise, zero-waste solution that eliminates these core problems. The transition to this safer, cleaner, and more efficient method is essential for the future of maritime maintenance.

In-Depth Case Studies: Practices of Global End-Users

The advantages of transitioning beyond traditional methods are not merely theoretical—they are being actively proven on the global stage. From naval forces to commercial shipyards, forward-thinking organizations are already implementing solutions that turn the promise of efficiency, safety, and sustainability into tangible results. The following case studies from diverse maritime sectors reveal the concrete pathways and measurable benefits of this operational transformation.

Hamburg Shipyard: Pulsed Laser Precision for Hull Care

Challenge:

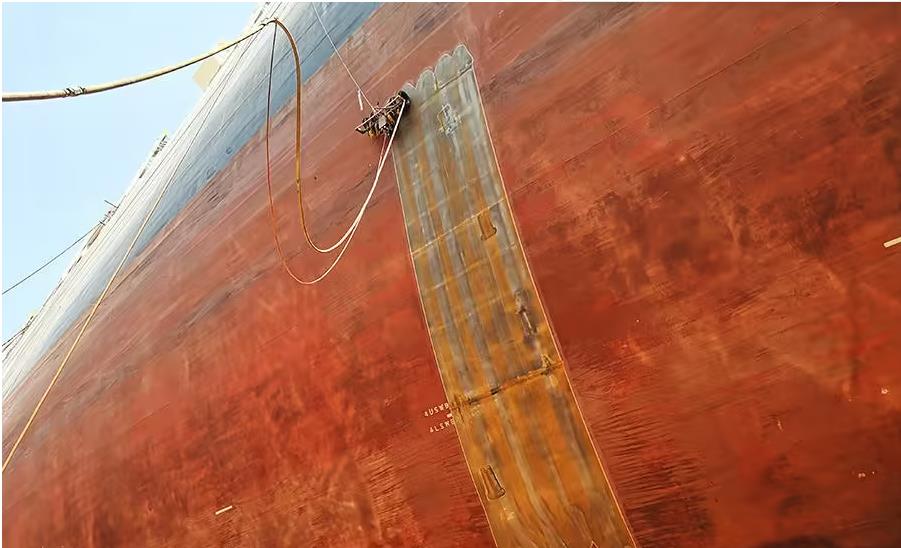

A Hamburg shipyard faced the critical challenge of removing stubborn marine biofouling from container ship hulls without damaging the expensive, specialized anti-fouling coatings. Traditional methods like abrasive blasting were non-selective, often stripping the entire coating layer. This necessitated a full reapplication, which was costly, time-consuming, and generated substantial hazardous waste.

Solution:

The shipyard implemented a nanosecond pulsed laser cleaning system. The technology’s core advantage is its “layered precision” – the ability to remove only the target material. By precisely calibrating parameters like wavelength and pulse duration, the system exploits the differing light absorption properties between organic fouling and synthetic paint. Integrated optical sensors provide real-time feedback, automatically stopping the process at the coating interface to prevent any substrate damage.

Key Benefits Demonstrated (Use Case Results):

Deployed on a 14,000 TEU container vessel, the laser system delivered measurable and significant advantages over traditional blasting:

-

Dramatic Cost Reduction: Saved approximately €135,000 per ship, comprising €120,000 in coating materials (due to 92% preservation) and €15,000 in avoided waste disposal costs.

-

Time and Labor Efficiency: Reduced drydock time by 4 days per maintenance cycle. This accelerated turnaround increases shipyard capacity and minimizes vessel downtime. The automated process also reduces manual labor and associated preparation/clean-up work.

-

Superior Coating Preservation: Achieved a 92% coating salvage rate, eliminating the need for a 100% recoating. This extends the coating’s protective lifecycle.

-

Environmental and Regulatory Compliance: The process generates zero secondary waste (no abrasives, no wastewater), ensuring full compliance with stringent environmental regulations and simplifying worksite logistics.

Conclusion:

This use case established pulsed laser cleaning machine as a standard, superior practice for hull maintenance at the shipyard. It transforms hull cleaning from a disruptive, resource-intensive operation into a precise, sustainable, and efficient process. The proven benefits in cost, time, and quality are driving further innovation, including R&D for in-water laser cleaning applications to potentially eliminate drydock requirements for this task.

Pearl Harbor Naval Shipyard, USA — Adopting Portable Laser Solutions for Fleet Maintenance

Challenge

Pearl Harbor Naval Shipyard & IMF faces intense pressure to reduce vessel downtime while maintaining nuclear carriers and submarines. Traditional cleaning methods like abrasive blasting are slow, requiring extensive containment setup and waste management. Each maintenance day delayed impacts fleet readiness, making faster, cleaner solutions critical.

Laser Solution

The shipyard adopted portable laser cleaners that can be brought directly to components onboard. Unlike blasting, this contactless method requires no containment, removes no base material, and generates no secondary waste—enabling in-situ cleaning without part disassembly or hazardous consumables.

Benefits & Results

-

Time & Labor Savings: Eliminates days spent on containment setup, media cleanup, and part transport. Direct on-site use streamlines workflow and optimizes crew deployment.

-

Zero Waste Operation: Produces no abrasives, slurry, or wastewater, removing associated handling and disposal costs while ensuring environmental compliance.

-

Precision & Flexibility: Enables targeted cleaning of sensitive areas without substrate damage, supporting stringent nuclear-grade standards and adaptable deployment across vessels.

Conclusion

Portable laser cleaning supports the shipyard’s strategic goal of cutting maintenance periods by 60–90 days. By replacing slow, waste-intensive methods, it turns cleaning time into operational readiness, proving essential for maintaining fleet availability in high-tempo environments.

Cruise & Polar Ship Maintenance in Finland — Precision Laser Cleaning for Critical Parts

Challenge

Maintaining polar-class vessels and icebreakers in Finland presents a unique challenge due to extremely short and costly drydock windows. Traditional abrasive cleaning methods are often too aggressive, risking damage to high-value precision components like propellers and shafts, and generate significant hazardous waste, prolonging downtime and post-processing.

Laser Solution

Finnish shipyards utilize pulse laser cleaning machine as a core restoration technology. Its non-contact, non-abrasive nature allows for the selective removal of rust and coatings from delicate parts with micron-level accuracy, preserving the original dimensions and integrity of the base metal.

Key Benefits

-

Significant Cost & Time Savings: The technology enables on-site refurbishment of critical components in days, avoiding weeks of lead time and saving hundreds of thousands of euros per part that would be spent on full replacements. It also eliminates all post-cleaning treatment time associated with abrasive waste.

-

Zero Damage & Waste: The process preserves the substrate perfectly, ensuring no loss of material on sensitive parts like heat exchanger tubes. It generates zero abrasive waste, removing disposal costs and environmental handling burdens.

-

Enhanced Performance & Longevity: By achieving a perfectly clean surface, it ensures optimal coating adhesion on hulls and restores the energy efficiency of systems like heat exchangers, directly extending vessel service life.

Conclusion

For Arctic vessel maintenance, pulse laser cleaning has become a strategic tool that turns precision refurbishment into direct economic advantage, ensuring reliability and smarter operations in the world’s toughest maritime conditions.

MOL Tackles Ship Rust, Environment, and Operations with Advanced Laser Technology

Challenge

Mitsui O.S.K. Lines (MOL) faced the environmental hazards and high operational costs of traditional hull sandblasting. The process generated toxic waste, posed severe worker health risks, and required extensive cleanup, prolonging dry-dock time.

Laser Solution

In a 2024 field test, MOL used an advanced laser system to clean a bulk carrier’s hull. This contactless technology precisely removed rust and coatings without abrasives, proving a viable and cleaner alternative under real dry-dock conditions.

Key Benefits

-

Zero Waste & Safer: The process eliminated all toxic blasting media and associated disposal, while removing health risks from airborne dust, creating a safer, compliant work environment.

-

Faster & Cheaper: By avoiding waste handling and cleanup, the method streamlined workflow and reduced labor, cutting both downtime and overall operational costs.

-

Precise & Automated-Ready: It achieved clean substrate exposure without steel damage, and its stability makes it ideal for future robotic automation to boost consistency.

Conclusion

MOL’s test confirms laser cleaning as a strategic upgrade for sustainable fleet maintenance, paving the way to fully replace sandblasting with a greener, more efficient standard.

Real-World Benefits: What the Data Shows

The documented results from global leaders like Hamburg Shipyard, Pearl Harbor Naval Shipyard, Finnish polar specialists, and Mitsui O.S.K. Lines provide conclusive evidence of laser cleaning’s transformative impact across maritime maintenance.

Technical Settings That Drive Results

Proven operational systems utilize nanosecond pulses at a 1064 nm wavelength, with energy densities calibrated between 1-15 J/cm². This precise tuning allows for the selective removal of contaminants like rust, biofouling, and coatings while preserving the integrity of the underlying marine-grade steel—a fundamental advantage over abrasive methods.

How Well It Cleans

Laser cleaning machine achieves exceptional surface preparation. For recoating, it removes over 95% to 100% of paints and coatings, with rust removal rates exceeding 98% on steel hulls. This directly enhances coating adhesion, extending service life. The success is evidenced by the Hamburg case study, which demonstrated a 92% coating preservation rate, and is further supported by academic research confirming complete coating removal.

Speed and Output

While portable units clean 1–5 m²/h, high-power systems can exceed 20–40 m²/h on large hulls. Crucially, the total project time is reduced by 30–60% compared to traditional methods, not merely by raw speed but by eliminating secondary processes like containment setup and waste cleanup. This aligns with the strategic goals demonstrated at Pearl Harbor (cutting 60-90 days from maintenance periods) and the Finnish case (reducing component refurbishment from weeks to days).

Impact on Materials and Precision

The process is non-destructive. It creates a minimal heat-affected zone (under 20 µm) and leaves surface roughness virtually unchanged, enabling repeated cleaning of high-value parts like propellers without dimensional wear. Research confirms that core material properties, such as tensile and bending strength of ship steel, remain fully intact.

Environmental Advantages

Laser cleaning delivers near-zero pollution. It eliminates over 95% of the hazardous waste and wastewater generated by blasting, ensuring direct compliance with global regulations. The environmental benefit—zero toxic blasting media—was a core, validated outcome in all four case studies, from MOL’s bulk carrier to naval nuclear vessels.

Conclusion

The era of costly, hazardous, and inefficient surface preparation is over. Laser cleaning technology offers the maritime industry a precise, clean, and sustainable alternative—proven today by leading shipyards and fleets worldwide. The transition is no longer optional; it is essential for staying competitive and compliant. Secure your advantage now: contact us to deploy your laser cleaning solution before the next maintenance cycle begins.