Selecting the right welding machine is a pivotal decision for your workshop’s productivity and growth. While both spot welding and laser welding are key technologies, they differ dramatically in application, performance, and cost. A mismatch can limit your capabilities, but the correct choice will enhance quality, efficiency, and flexibility. This concise comparison breaks down their core differences, helping you make an informed decision tailored to your specific workshop needs.

Spot Welding Machine vs. Laser Welding Machine: Core Comparison

| Comparison | Spot Welding Machine | Laser Welding Machine |

| Weld Result | Nugget joints with indentations, more distortion. | Continuous seams, aesthetic, minimal distortion. |

| Material Range | Best for steel sheets, limited material compatibility. | Versatile: steel, aluminum, copper, dissimilar metals. |

| Productivity | Fast per spot, low efficiency for multi-spots, complex automation. | Continuous high-speed welding, easy automation & flexibility. |

| Cost of Use | Low machine price, but high consumables, frequent maintenance, needs skilled welder. | High cost-performance (from $2,500), no consumables, maintenance-free, quick to learn. |

| Best For | High-volume standardized production, very tight budget. | Precision products, long-term competitiveness. |

How Spot Welding Machine and Laser Welding Machine Work

Spot Welding Machine creates joints through resistance heat. Two copper electrodes clamp the overlapping metal sheets and deliver a massive current burst. This current generates intense localized heat at the contact point, instantly melting the metal to form a fused nugget within milliseconds. The process follows a precise four-stage cycle: squeeze, weld, hold, and release, ensuring a strong bond under pressure.

Detailed Comparison Between Spot Welding and Laser Welding Machine

1. Weld Quality and Strength

-

Spot Welding: The integrity of the joint is entirely dependent on a properly formed nugget at each point. The process inherently creates visible indentations on the workpiece surface due to electrode pressure. Furthermore, the heat-affected zone (HAZ) surrounding each nugget is relatively broad, which can induce more significant thermal distortion in the surrounding material, potentially affecting part flatness and dimensional accuracy.

-

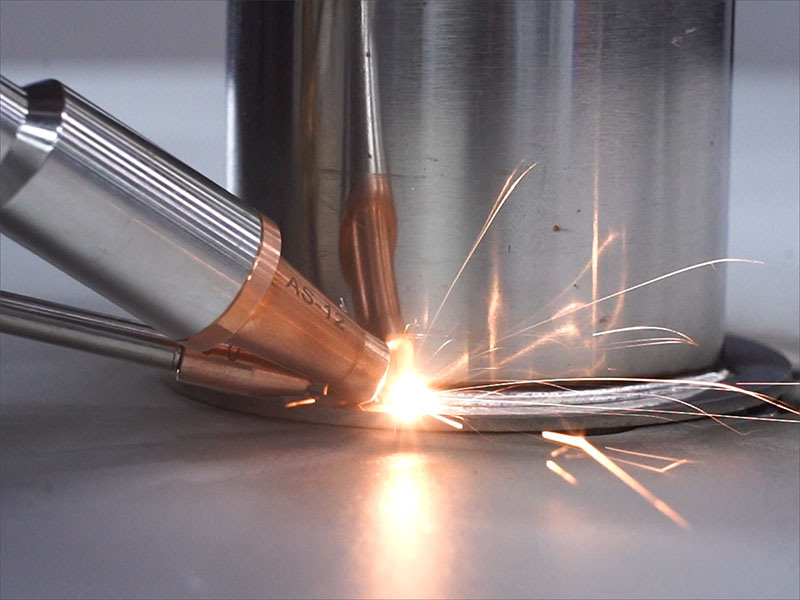

Laser Welding: This method produces continuous, homogeneous seams that are not only aesthetically superior with a smooth finish but also structurally robust. By concentrating energy into a microscopic point, it achieves a very high depth-to-width ratio, resulting in deep penetration with minimal heat input. This leads to exceptional joint strength, superior fatigue resistance, and excellent sealing properties, making it the definitive choice for applications requiring hermeticity or bearing dynamic loads.

2. Processing Capability and Material Range

-

Spot Welding: Its applicability is fundamentally constrained by electrical conductivity. It is most effective on conductive ferrous sheets like low-carbon and stainless steel in overlapping configurations. Welding materials with high thermal conductivity, such as aluminum alloys, is notoriously challenging. It requires specialized, often expensive, equipment settings and surface treatments to overcome issues like rapid heat dissipation and surface oxide layers, and even then, results can be inconsistent.

-

Laser Welding: It boasts remarkably broad material compatibility. The process is not dependent on electrical conductivity, allowing it to weld steel, aluminum, copper, titanium, and even challenging dissimilar combinations like aluminum-to-steel or copper-to-brass. It excels in extreme applications, from joining ultra-thin foils without burn-through to penetrating thick sections, and is equally capable with reflective or exotic alloys that are problematic for most other welding methods.

3. Production Efficiency and Automation

-

Spot Welding: While the cycle time for creating a single spot is extremely fast, this speed is offset when multiple points or long seams are required. Each spot needs individual electrode positioning, making the process inherently sequential and limiting overall throughput. Achieving full automation for complex parts demands elaborate fixtures and often multiple welding guns operating in tandem, increasing system complexity and cost.

-

Laser Welding: It is synonymous with high-speed, continuous joining. The non-contact beam can travel at several meters per minute along seams. Its greatest advantage for modern manufacturing is seamless robot integration. A single robotic laser cell can effortlessly perform long, continuous welds and intricate 3D contours on multiple part variants without any tooling changes, enabling truly flexible, lights-out automation for high-mix, low-volume production.

4. Operational Cost and Investment

-

Spot Welding: The primary appeal is the lower initial purchase price of the machine itself. However, this is misleading for total cost of ownership. It incurs substantial recurring costs from frequent replacement of consumable copper electrodes, regular maintenance of mechanical arms and transformers, and higher energy consumption. Furthermore, it often requires a skilled operator to set parameters and ensure quality, adding labor cost and expertise dependency.

-

Laser Welding: The traditional view is of high capital investment, but this narrative is changing significantly. For instance, our company’s advanced fiber laser welders start at an unbeatable price of just $2,500, disrupting market expectations. More importantly, operational costs are drastically lower. They utilize a fiber laser source with a 100,000-hour lifespan, are virtually consumable-free, and are designed for maintenance-free operation. Crucially, they are incredibly easy to learn; a complete novice can master basic operations in 5-10 minutes, eliminating the need for expensive specialist welders.

5. Workshop Requirements

-

Spot Welding: It places significant demands on workshop infrastructure, requiring a robust, high-capacity electrical supply to deliver the intense bursts of current. The process generates considerable noise and molten spatter, necessitating protective barriers for operators and equipment, and contributing to a generally harsh shop floor environment. Managing this spatter and the resulting fumes also requires attention.

-

Laser Welding: Safety is paramount and revolves around containing the laser beam. Modern machines like ours are engineered as fully enclosed, Class 1 laser-safe systems, meaning they are perfectly safe for operation in any open workshop with no special precautions needed for bystanders. While fume extraction is recommended for any welding process, the total fume volume generated is typically less than arc welding processes. The primary requirement is simply a standard power outlet, not a heavy industrial electrical feed.

Decision Guide — Making the Right Choice for Your Future

When to Consider a Spot Welding Machine:

-

Your production is focused on high-volume runs of simple, standardized sheet metal assemblies like automotive panels or cabinets.

-

You operate under a strictly limited budget where the absolute lowest upfront cost is the primary deciding factor.

-

You work exclusively with conductive materials like mild steel, and your designs only require overlapping spot joints.

When a Laser Welding Machine Becomes the Essential Choice:

-

You manufacture products where precision and superior finish are critical, such as consumer electronics or medical devices.

-

Your work involves diverse materials (like aluminum, copper, or stainless steel), dissimilar metals, ultra-thin sheets, or requires hermetic seals.

-

You need maximum flexibility to handle rapid design changes, small batches, and complex weld geometries without retooling.

-

You are investing in long-term capability, seeking one machine that can perform tasks ranging from simple spot welds to intricate continuous seams and 3D contours.

-

You value operational simplicity, lower total cost of ownership, and wish to eliminate dependency on skilled welders and frequent consumable changes.

While a spot welder handles basic tasks, a laser welder offers a superior and future-proof solution. It ensures better weld quality and the flexibility to take on new projects without replacing your core equipment.

Conclusion

Choosing the right welding technology is a critical investment in your workshop’s future productivity and versatility. Our advanced fiber laser welding systems provide a definitive solution by consolidating multiple capabilities into one robust platform—overcoming traditional limitations and unlocking new fabrication possibilities. More than just a machine, this is an investment in long-term resilience, operational simplicity, and lasting competitive advantage. Contact us today to discover how our laser welder can transform your production.