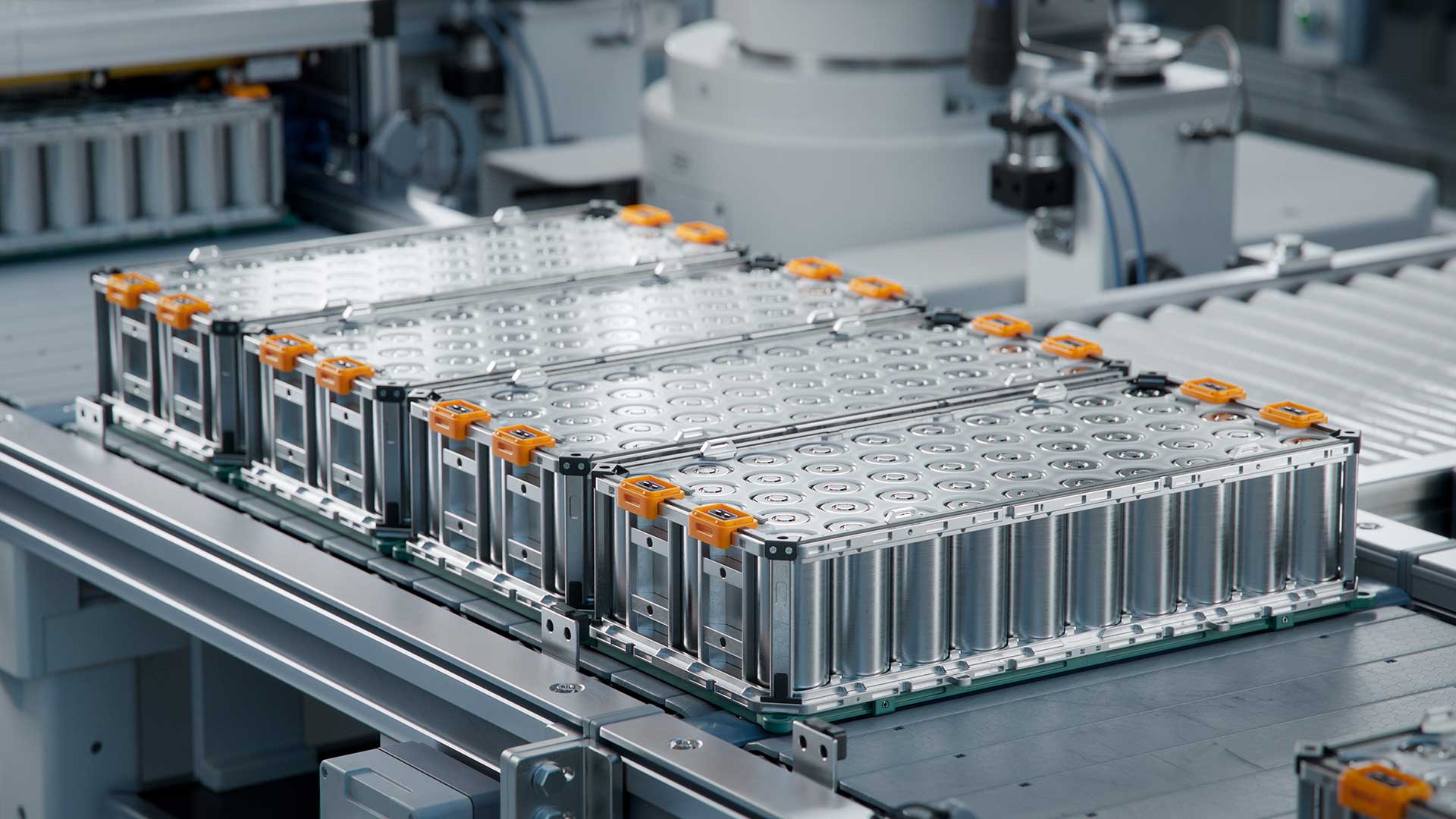

In lithium-ion battery manufacturing, welding may seem like a minor process, but it directly affects battery safety, consistency, and service life. This battery welding comparison focuses on the two most widely used technologies today—spot welding and laser welding—which represent very different approaches: one is known for its maturity and cost-effectiveness, while the other is rapidly gaining attention for its high precision and automation potential. As quality requirements continue to rise, which welding method is truly better suited for lithium-ion batteries? This article provides a clear and in-depth comparison from the perspectives of working principles, performance, and real-world applications.

Spot Welding vs. Laser Welding: Key Differences at a Glance

This table takes a look at spot welding vs laser welding, showing their key features, pros, and cons for lithium-ion batteries, so manufacturers can quickly see which one works best for their production.

|

Key Feature |

Resistance Spot Welding |

Laser Welding |

|

Initial Investment |

Low: Budget-friendly and simple setup. |

High: High CAPEX for optics and safety. |

|

Production Speed |

Moderate: Manual/Semi-auto (0.5–1s/spot). |

Ultra-Fast: High-speed (10–50 spots/sec). |

|

Precision & HAZ |

Lower: Physical pressure; larger Heat-Affected Zone. |

Superior: Concentrated energy; minimal heat stress. |

|

Material Versatility |

Limited: Best for Nickel; difficult for Copper/Alu. |

High: Excellent for Copper, Aluminum, and Busbars. |

|

Automation |

Challenging: Requires frequent electrode dressing. |

Excellent: Fully digital; ideal for robotic lines. |

|

Consumables |

High: Frequent electrode replacement required. |

Low: Minimal (protective windows/gas). |

|

Best Application |

Prototyping, E-bikes, and small electronics. |

EV Batteries, ESS, and Mass Production. |

Spot Welding Technology: Principle and Application in Lithium-Ion Battery Work

Resistance spot welding uses high current to melt the metal at the contact point between the nickel strip and battery tab, forming a small weld nugget. The process lasts only milliseconds, keeping heat localized, while electrode pressure ensures a strong, reliable joint.

Equipment Settings for Lithium Battery Work

Modern spot welders built for battery pack work use these settings:

-

Cylinder pressure: 35-95 PSI (0.24-0.65 MPa) for nickel strip welding. Thicker strips need more pressure

-

Production speed: Automated systems reach 4,500 pieces per hour on one machine

-

Current control: You can program waveforms with multi-pulse modes. These include preheat, main weld, and tempering phases

-

Quality monitoring: The system tracks current, voltage, resistance changes, and displacement in real-time

The battery welding equipment market shows this trend. Market size grew from $450 million in 2024. It’s headed toward $1.2 billion by 2033.

Quality Standards and Testing

Your weld quality rests on four factors:

Mechanical strength: Peel tests check single-point separation force. Premium battery packs pass a key test. The nickel strip tears before the weld breaks.

Electrical performance: Low contact resistance stops hot spots during high-rate discharge. Automated systems use inline resistance and voltage checks. These catch bad welds.

Appearance criteria: Nugget diameter fits strip thickness. You see no spatter or burn-through. Multiple welds keep proper spacing. This ensures electrical isolation and structural strength.

Process control: Advanced equipment tracks current, voltage, and displacement curves in real-time. Quality feedback systems sound alarms. They reject bad welds on their own.

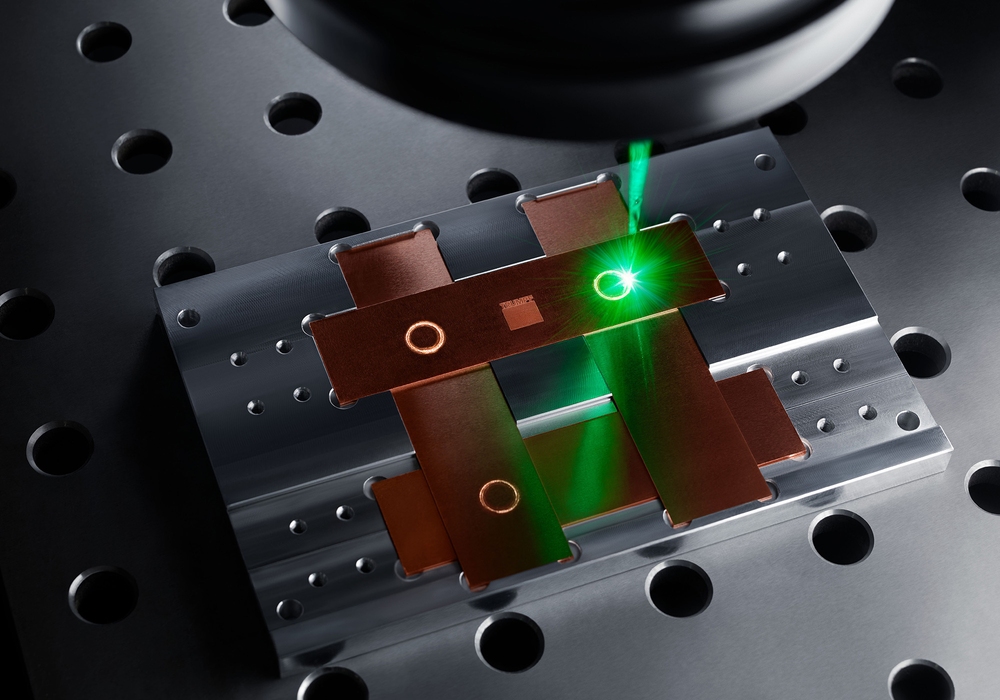

Laser Welding Technology: Principle and Advantages for Battery Manufacturing

Laser welding uses a focused beam to melt metal almost instantly, forming strong, fast-solidifying welds. In battery production, keyhole welding creates deep joints, while conduction welding ensures precise, controlled connections, keeping heat zones small and welds clean.

Laser Types and Their Battery Welding Performance

Fiber lasers lead battery manufacturing. Power output ranges from 1–6 kW for most cell welding tasks. Busbar and current collector welding needs 8–12 kW.

Single-mode fiber lasers focus down to 60–70 µm spot size. This precision works well for battery tab welding and cell sealing. The beam works with steel, nickel, aluminum, and copper—plus their plated versions.

Blue and green wavelength lasers fix a key problem. Copper and aluminum bounce back traditional infrared lasers. These shorter wavelengths cut through this issue. You get stable welds with less mess. Your electrical flow stays steady.

CO₂ lasers use 10.6 µm wavelength. Copper and aluminum reflect them too much for battery tabs. Larger focal spots reduce precision. The industry stopped using these for battery cell connections.

Speed and Quality Control That Scales

Laser welding speed has improved dramatically, increasing from about 60 mm/s in 2017 to as high as 500 mm/s today. As a result, modern production lines can process around 40 prismatic cells per minute, compared with only eight a decade ago. With dual-beam fiber lasers and real-time monitoring systems, weld depth is checked during welding, allowing defects to be corrected instantly and ensuring consistent quality for every weld.

Contact-Free Operation Benefits

No electrodes wear out. No ultrasonic horns need swapping. Your maintenance costs fall versus resistance or ultrasonic methods. The laser head never touches your workpiece. No risk of dirt getting in. Battery parts stay safe from physical stress.

Heat-Affected Zone (HAZ) Comparison: Impact on Battery Safety and Longevity

Every battery welding process creates a heat zone around the weld. This zone determines how safe your battery stays and how long it lasts.

Spot Welding HAZ: Size and Temperature Reality

Resistance spot welding spreads heat into battery tabs and busbars, creating a heat-affected zone (HAZ) around each weld. This zone is about 0.8–1.5 mm wide for cylindrical and prismatic cells, but can expand to 1.5–3 mm in aluminum pouch-cell tabs due to faster heat conduction. Temperatures near the weld can reach 600–900 °C, and overlapping welds may form a wider weakened area in the tab that becomes prone to failure under stress.

Material Degradation From Spot Welding Heat

When spot welding heats aluminum tabs above 300 °C, the material softens, losing 20–40% of its hardness and strength and forming a weak zone about 0.5–1.0 mm wide. Nickel-plated copper tabs also suffer grain coarsening near the weld, cutting fatigue life by over 50%. Under high-rate cycling and vibration, poor welds can crack after just 500–1,000 cycles, while optimized settings may extend this to 2,000–3,000 cycles—still far below the durability of unwelded tabs.

Laser Welding HAZ: Precision Control

Laser welding shrinks the heat zone significantly. Industry data shows laser HAZ measures 0.2–0.4 mm wide. Spot welding HAZ spans 1–2 mm. The ratio hits 1/5 to 1/4.

These process parameters drive this precision:

– Spot size: 0.1–0.3 mm diameter

– Weld width: 0.3–0.6 mm

– Total HAZ: Under 1 mm

– Peak heat duration: Under 10 milliseconds

Continuous laser seam welding concentrates heat in a narrow band. Non-welded tab root areas stay below 100–150°C. Multiple spot welds create overlapping zones above 200°C. This difference protects your battery.

Safety Impact on High-Energy Cells

High-energy-density batteries are more sensitive to heat, and overheating at the tab can damage internal materials, raise resistance, and increase thermal runaway risk. Reducing the heat-affected zone helps control temperature, keep resistance stable, and extend battery life under fast charging and high-power use.

Welding Precision and Quality Control: Accuracy, Defect Rates, and Consistency

Precision in your battery manufacturing equipment separates reliable battery packs from ones that fail in the field. Your welding method controls three quality factors: positioning accuracy, defect occurrence, and batch-to-batch consistency.

Spot Welding Precision Challenges

As spot-welding electrodes wear, the tip widens and weld size becomes less consistent, leading to smaller nuggets and more weak welds if maintenance is delayed. Positioning errors from robots or fixtures can further shift welds off center, especially in thin materials, reducing strength and increasing defects. In high-volume production, these effects add up, but real-time electrode monitoring and timely tip maintenance can keep weld quality stable and defect rates low.

Laser Welding Precision Advantages

Vision guidance systems track weld positions with very high accuracy and adjust in real time during high-speed welding. This is especially valuable for multi-layer battery tabs, where small misalignments are common—cameras and sensors automatically detect edges and correct the weld path. The result is fewer off-center welds, more consistent joint quality, faster production, and much lower defect rates compared with spot welding.

Production Speed and Throughput: Cycle Time and Automation Potential

Cycle time determines how many battery packs you ship each day. Pick spot welding or laser welding. This choice creates a 3–5× difference in production speed.

Spot Welding Cycle Time Reality

Resistance spot welding itself is fast, but once you include electrode movement, pressure, holding, and release, each weld point typically takes about 0.8–1.0 seconds in automated setups. In theory, that means one welding gun can produce up to 4,000 points per hour, but in real production, handling, positioning, and inspections reduce output to about 60–80% of that. In practice, a single gun usually delivers around 2,400–3,600 welds per hour, while multi-gun fixtures can scale this much higher. Overall output depends heavily on equipment efficiency, with high-end lines performing significantly better than standard automation.

Laser Welding Speed Advantage

Laser welding is much faster than spot welding because it can weld continuously without stopping for individual points. Typical laser speeds range from 30–200 mm/s, compared with an effective 20 mm/s for spot welding. For example, welding both sides of an 800 mm module takes 16–27 seconds with a laser versus 80 seconds with spot welding, and a 5-meter weld drops from over 4 minutes to under a minute. This 3–5× speed advantage significantly boosts production output on the same floor space.

Cost Analysis: Equipment Investment, Operating Expenses, and ROI

Your budget picks the welding technology for your production floor. Equipment prices range from low to high. Each method racks up different operating costs. Your ROI ties to production scale and quality needs.

Initial Equipment Investment Breakdown

Spot welding systems for batteries vary by complexity:

-

Entry-level units: $4,300–$11,400

-

Mid-range automated stations: $11,400–$35,700

-

Premium lines with fixtures: $35,700–$114,000

Laser welding systems require a higher upfront investment:

-

Entry-level stations: $57,200–$114,000

-

Mid-range setups: $114,000–$214,500

-

High-end multi-station systems: $214,500–$429,000

When scaling to full production lines, costs increase:

-

Spot welding lines: $143,000–$429,000

-

Laser welding lines: $286,000–$858,000

Although laser welding costs 1.5–3× more per weld point than spot welding, its higher speed, precision, and automation potential allow you to produce more units in less time, reduce defects, and quickly offset the initial investment—making it the smarter choice for high-volume, high-quality battery production.

Operating Cost Comparison

The ongoing costs of spot welding and laser welding mainly come from consumables and electricity. Spot welding electrodes cost about $0.54–$1.40 per pair, with lifespans of 2,000–15,000 welds depending on material, translating to a tiny per-weld cost of $0.000007–$0.00007.

Laser welding consumables are mainly protective lenses, $1.40–$4.20 each, lasting 100,000–500,000 welds, or $0.000005–$0.000035 per weld. Fiber and focusing optics last 1–3 years, making consumable costs almost negligible in high-volume production.

Power consumption: spot welders average 1–3 kW, while 1 kW laser systems use 2–4 kW and high-power 2–4 kW systems 4–8 kW, with cost per weld depending on speed and cycle time. Overall, while laser welding requires a higher upfront investment, it offers much lower per-weld consumable and energy costs, along with higher efficiency. For high-volume, high-precision battery production, it is not only more economical in the long run but also more sustainable and reliable.

Conclusion

In lithium-ion battery production, every weld affects safety, performance, and lifespan. While spot welding has served the industry for decades, laser welding excels in speed, precision, and long-term cost efficiency. Continuous seam welding, minimal heat-affected zones, ultra-low per-weld consumable costs, and vision-guided systems mean faster production, fewer defects, and longer-lasting batteries. For manufacturers aiming to scale up and stay competitive, investing in a high-quality laser welding system is the smarter, future-proof choice—turn every weld into a clear advantage. Contact us today to learn how our laser welding solutions can transform your production line and boost your output.