Stripping paint from a spindle chair is a restorer’s nightmare. Chemical strippers seep into delicate wood grain, sanding destroys fine details, and hours of scraping leave you exhausted—often with a damaged piece. What if there was a method that lifted paint away like magic, leaving pristine, untouched wood beneath? This isn’t fantasy; it’s laser cleaning technology.

For furniture restorers, DIY enthusiasts, and professional shops, laser cleaners are revolutionizing paint removal by offering a fast, precise, and remarkably gentle solution. This guide explores why a laser cleaner might be your ultimate tool for bringing beautiful spindle chairs back to life.

Understanding Laser Paint Removal Technology

Laser paint removal works differently than traditional stripping methods. A focused fiber laser beam creates intense heat. This heat vaporizes paint layers instantly.

The beam never touches the surface beneath. This non-contact process protects delicate wood spindles. You won’t get gouging, scratching, or damage like you would with scrapers or heavy sanding.

How the Technology Works

The system lets you adjust power levels and pulse settings. You can customize these based on what you need. Fiber laser systems handle most furniture restoration jobs. They’re now the main technology for removing paint from wood and metal surfaces. These systems range from 300 watts up to 1000 watts or more. The wattage depends on how complex your project is.

The precision is remarkable. Laser cleaners achieve micro-level removal accuracy. This lets you target specific areas on detailed chair spindles. Surrounding surfaces stay untouched. You can dial in the exact power to remove paint. The original wood grain underneath stays preserved.

Speed and Efficiency Metrics

Modern laser systems deliver impressive removal rates:

-

15-20 square centimeters per second for standard applications

-

Up to 15 square feet per hour with fiber laser systems

-

300W pulse laser systems can strip up to 15 square meters of coating per hour

-

Advanced models reach 20 square meters per hour on larger projects

These numbers mean a 50% speed advantage over abrasive techniques like sanding or chemical stripping. Automotive manufacturing companies have seen results. They achieved up to 70% reduction in rust treatment times after adding laser technology to their workflows. This same benchmark applies just as well to furniture restoration projects.

Assessing Your Chair and Paint Type

Before you start removing paint with a laser cleaner, know what you’re working with. The wood type and paint finish determine your laser settings.

Identifying Your Chair’s Wood Type

Different woods react in different ways to laser paint removal. Each type has unique traits that affect the stripping process:

-

Oak shows prominent grain patterns with warm yellow undertones

-

Mahogany features deep red undertones and rich color variations

-

Pine displays a yellow base with visible knots that may affect laser penetration

-

Walnut presents cool brown tones with natural color variations

-

Maple offers pale neutral tones and accepts laser treatment well

These wood traits matter. You must adjust laser power based on wood density and grain structure. Harder woods like oak and walnut can handle higher wattage settings. Softer woods like pine need gentler treatment. This prevents scorching.

Evaluating Paint Type and Layers

The paint composition impacts your laser cleaning strategy. Test the paint compatibility before you proceed:

Oil-based paints vaporize clean under laser treatment. But they may need multiple passes. Water-based paints remove faster with lower power settings. Silicone-based coatings present challenges. They resist most removal methods. You may need chemical pre-treatment before laser work.

Check the finish type. Glossy surfaces reflect more laser energy than matte finishes. You’ll need to increase power levels by 10-15% for high-gloss paints. Perform a scratch test on a hidden spindle area. This assesses paint adhesion strength.

Multi-layer paint situations need patience. Laser cleaners excel at removing layers one by one without damaging the wood beneath. But you must work from top to bottom.

Step-by-Step Process: Using Laser Cleaner on Spindles

Good prep and a clear plan make laser paint removal work. Follow this workflow to strip paint from chair spindles.

Configuring Laser Parameters

Start low and go higher if needed. Set your frequency range between 0-20 based on how thick the paint is. Go with the lower end for thin paint. Set the duty cycle to 100 for steady power. Turn on the master laser enable button first. This safety feature stops accidental firing.

Keep the air delay at factory settings. Most furniture jobs don’t need changes here.

Chair spindles with thick paint? Pulsed laser mode gives better results. Pulsed beams remove paint faster. They work better than a steady beam. Pulsed action creates quick plasma bursts. These bursts break up paint but leave the wood fine.

Executing the Removal Process

Hold the laser head 6-8 inches from the spindle surface. Test it first on the bottom or a hidden part. Move the beam along the spindle in smooth, overlapping passes. The focused beam breaks paint down at a molecular level. You’ll see layers vanish right away.

Go around each spindle piece by piece. Turn the chair or move yourself to keep the beam angle right. The non-contact method means no scratches or gouges on the wood. Your spindles stay smooth and accurate through the whole job.

Look for plasma forming as you work. The high-frequency pulse makes plasma expand fast. This creates shock waves. These waves make paint chunks fall off clean. The wood underneath stays perfect—no damage to the surface or finish.

Inspecting the Cleaned Surface

When inspecting the surface after cleaning, the focus is on verifying the precision and non-destructive effect of laser cleaning. The non-contact nature of laser ensures the integrity of the wood surface structure, free from mechanical damage or heat marks.

Under sufficient lighting, visual inspection should confirm complete coating removal, with clear wood grain and no residue. As the laser energy is precisely controlled, it typically leaves no burn marks or rough areas, eliminating the need for subsequent steps such as sanding—truly achieving “clean and ready.”

Post-Treatment Surface Preparation

After you remove paint, laser cleaning creates an anchoring effect on the wood. This adds texture and surface area. Great for glue or finish to grip if you’re refinishing. The process also gives precise control over how liquids spread for even stain or finish.

Laser treatment removes small rough spots and raised bits that create weak points. This cuts down on rust risk later. It also stops problems with static discharge if your chairs go into sensitive areas. No chemicals means no fumes and no toxic waste.

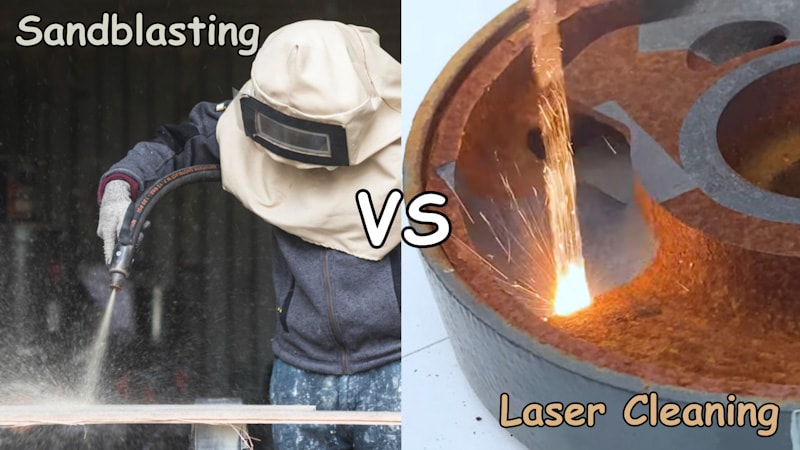

Comparing Laser Cleaning vs Traditional Methods

The decision between laser and traditional cleaning extends beyond upfront cost to encompass processing speed, cleaning effectiveness, material safety, and long-term operational impact. The following comparison highlights these critical differences:

| Factor | Laser Cleaning | Traditional Methods |

| Overall Cost | Medium upfront, very low long-term | Low upfront, high long-term cost |

| Processing Speed | Extremely Fast | Slow |

| Maintenance | Minimal | High wear & upkeep |

| Cleaning Effect / Residue | Thorough, residue-free | Often leaves residue or embedded dust |

| Risk of Substrate Damage | Non-contact, zero damage | High risk of scratches, wear, or deformation |

| Chemical Waste / Toxicity | None | High (toxic residues) |

| Airborne Emissions / Dust | None / Minimal | High (hazardous dust & fumes) |

As demonstrated, laser cleaning redefines the restoration process by combining extreme speed with flawless results. It achieves complete coating removal without residue and guarantees zero physical damage—all in a fraction of the time required by conventional methods. This is not merely an improvement, but a transformative advancement that sets a new standard for efficiency, quality, and safety in restoration work.

Conclusion

A laser cleaner transforms restoration from a tedious task into a controlled, efficient process. It delivers not only speed but also the confidence to preserve even the most delicate pieces to the highest standard.Experience professional-grade precision with MAXWAVE. We offer a full range of solutions, from precise pulsed to high-efficiency continuous wave lasers, all built with a focus on safety, reliability, and robust design.