Have you ever struggled with rust, old paint, or stubborn grime that just won’t come off—no matter what cleaning method you try? That’s exactly why laser cleaning has become a game-changer. In this complete beginner’s guide, I’ll share expert tips gained from years of hands-on experience, showing you how this advanced yet surprisingly simple technology works, where it can be used, and why more and more industries are switching to it.

What is Laser Cleaning and Why I Think It Matters

Laser cleaning is a modern technique I find very useful. It uses a focused laser beam to remove things like rust, paint, and dirt from a surface. I believe what makes this process special is that it doesn’t need chemicals or rough materials. This makes it a much safer and greener choice than older cleaning styles.

How Laser Cleaning Works

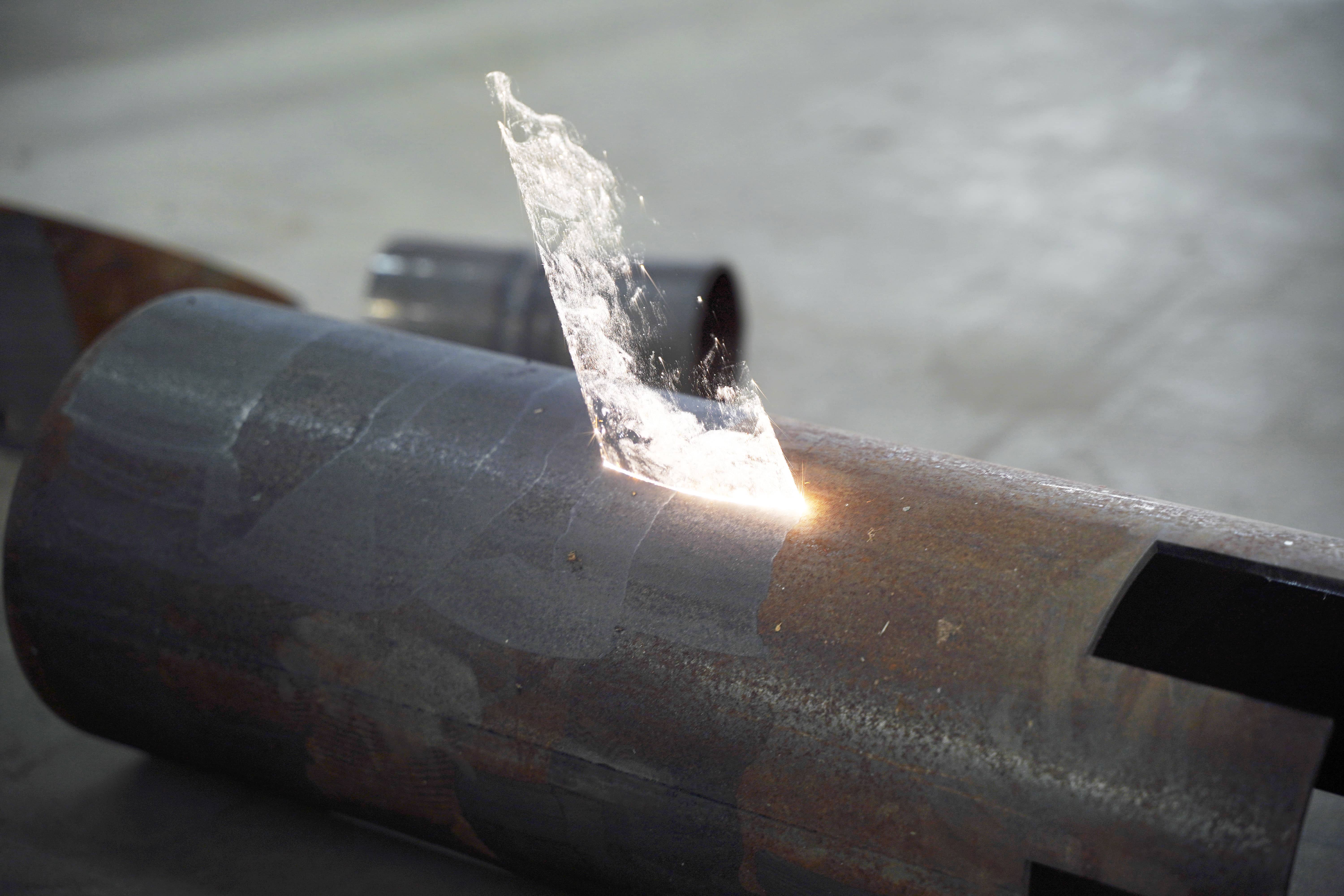

Laser cleaning uses a focused beam to remove rust, paint, or grime from surfaces. From my experience, the laser vaporizes contaminants without harming the material underneath, and the process produces no chemical residue or extra waste.

My Favorite Benefits of Laser Cleaning

It’s eco-friendly since no harsh chemicals are used. The laser is highly precise, cleaning tiny spots without affecting nearby areas. It’s also safe for operators because it’s controlled and non-abrasive.

Where I Recommend Using Laser Cleaning

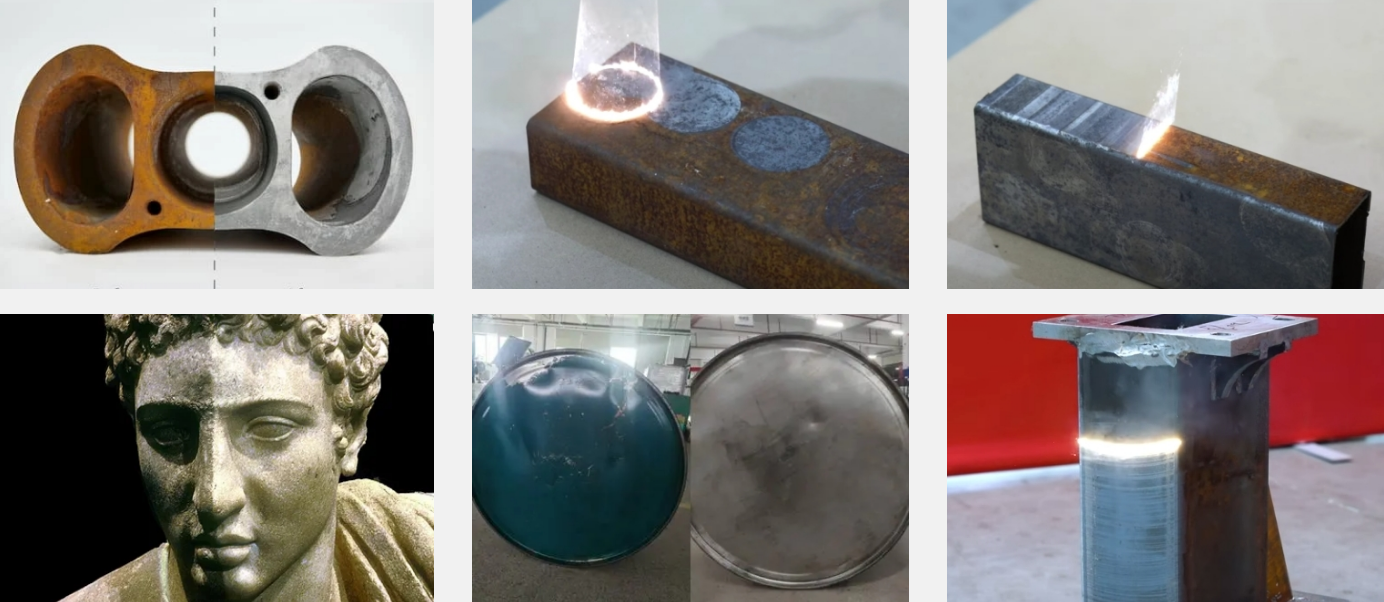

Laser cleaning works in many industries. It’s great for cars to remove rust and paint, for airplanes to prep sensitive parts, and for restoring historical statues or artwork. In factories, it quickly cleans machines and tools, saving time and effort.

Based on my experience, even if you are new to this, you can get great-looking, professional results. You just need to follow simple instructions. This is why I suggest laser cleaning for almost anyone. It works for experts and for beginners who need a good way to clean and fix up surfaces.

How Laser Cleaners Work: An Expert’s View

Laser cleaner uses a process I know well: laser ablation. A high-energy laser beam hits the unwanted material on a surface. It then turns that material into vapor. From my experience, the use of precision optics and advanced control systems is what makes this so special. These systems direct the energy to the exact spot you need to clean.

Key Features I Look for in Laser Ablation

- Protects the Base Material: The laser’s focused energy removes dirt and rust. I find it does this without scratching or damaging the surface underneath.

- Flexible Power Settings: I suggest adjusting the laser’s power and pulse. This makes it safe to use on a wide range of items. You can clean delicate antiques or tough industrial metal.

- Clean Operation: A great feature is the built-in vacuum. It sucks up all the vapor and dust. This keeps your workspace clean and safe.

Based on my experience, this mix of targeted cleaning, flexible settings, and a clean process is why I recommend laser cleaners for so many jobs.

Types of Laser Cleaner Machines

For laser cleaning, there are two primary types of machines: Continuous Wave (CW) Lasers and Pulsed Lasers. Based on my experience, each has unique strengths depending on the job.

Continuous Wave (CW) Lasers

- Best for: Cleaning large surfaces. I use them to remove thick layers of rust or paint.

- Advantages: Their high power lets you cover big areas fast. This saves a lot of time on industrial jobs.

- Drawbacks: The constant heat can damage sensitive materials. I suggest not using them for delicate tasks or valuable items.

Pulsed Lasers

These lasers shoot out short, high-energy bursts instead of a steady beam.

- Best for: Careful, precise cleaning. I think they are great for items with detailed surfaces or sensitive base materials, like historical artifacts or electronics.

- Advantages: They generate very little heat, which makes them safe for fragile surfaces. They are also very accurate, so you can target dirt without affecting nearby areas.

- Drawbacks: They usually come with a higher price tag. I also find they require more attention when adjusting the cleaning settings to get the best results.

Pro Tip: I recommend a CW laser if you need to remove stubborn grime from tough surfaces fast. For historical objects or anything where the surface underneath is fragile or valuable, I suggest a pulsed laser for its safe and precise cleaning.

Typical Applications of Laser Cleaning

I find laser cleaning impressive. It cleans powerfully but doesn’t damage surfaces. Based on my experience, here are a few common ways I’ve seen laser cleaners being used:

Automotive and Vehicle Maintenance

In the auto industry, lasers are widely used to strip rust, paint, and grime from car parts and frames, even cleaning sensitive components safely. They’re also ideal for preparing metal surfaces before repainting, ensuring the new coat adheres better and lasts longer. On average, this service costs around $200–$800 per car, depending on vehicle size and job complexity.

Industrial Machinery and Tool Maintenance

Factories use laser cleaner machines to restore machinery and tools by removing rust, grease, and buildup. They’re especially useful before welding, as they clean the metal for stronger bonds and better joints. Since the process doesn’t wear down tools, it extends their lifespan and helps businesses save on replacement costs.

Art Conservation and Heritage Restoration

Laser cleaning is ideal for delicate work like monuments, artifacts, statues, and old stonework, as it removes dirt without scrubbing or scratching, protecting original materials and fine details. It’s especially valued in heritage projects where precision is critical. Pricing typically starts at $500 per project and increases with size and complexity.

Electronics and Precision Industries

In electronics, lasers are excellent for detailed cleaning, removing residue, burn marks, and oxide layers from circuit boards without damage. They can target tiny spots without heat, making them ideal for sensitive, high-value components where other methods are too harsh.

Aerospace and Aviation

In aerospace, lasers are used to clean and prepare aircraft surfaces, ensuring strong, pure metal bonds for safety and performance. They also create ideal surfaces for coatings, making repairs more reliable and longer-lasting.

In my opinion, the bottom line is this: laser cleaning is a targeted, touch-free method. It gives you great results and protects your valuable items, from a machine to a piece of history.

Advantages of Laser Cleaning

From my experience, laser machine for cleaning offers some major benefits. I’ve seen it make a huge difference for both tough industrial jobs and delicate tasks. Here are the main advantages I think are important:

No Solvents or Chemicals Needed: Laser cleaning works without harsh chemicals, making the workplace safer and more eco-friendly while avoiding toxic waste.

Protects Underlying Surfaces: It removes rust, paint, and grime without damaging the base material, keeping even sensitive artifacts and electronic parts intact.

Fewer Consumables, Lower Ongoing Costs: With no need for brushes, pads, or cleaning fluids, the main expense is just electricity, keeping long-term costs very low.

Compatible with Robots and CNC Automation: Laser cleaners integrate easily with robotic arms and CNC systems, enabling accurate, automated cleaning with less manpower.

Reduces Downtime and Improves Efficiency: The process is fast and easy to set up, minimizing production stops and significantly boosting operational efficiency.

Industry Insight, Real Cost Savings: Factories often cut cleaning costs by 30–40% annually after switching to lasers, thanks to fewer supplies, lower waste disposal, and reduced downtime.

Operating a Laser Cleaner: Step-by-Step

Laser cleaning machine is a powerful tool. To use it safely and get good results, you need to follow the proper steps and take the right precautions. Here is my personal step-by-step method, which I’ve developed from years of hands-on work.

Essential Preparation and Safety Checklist

Always start with proper Personal Protective Equipment (PPE), including laser safety goggles for your wavelength, sturdy gloves, and protective clothing. Work in a well-lit, ventilated area free of flammable materials to manage dust and fumes safely. If others are nearby, use barriers and warning signs to protect them from stray beams.

Equipment Setup and Calibration

Before starting, inspect the laser for faults, loose plugs, or damaged cables to prevent accidents and delays. Adjust power, pulse frequency, and spot size based on the material, and always follow the manufacturer’s manual for proper settings.

Cleaning Operation: My Proven Workflow

- I always focus on a small test area first. Try to pick a spot that is not easily seen before you work on the whole surface. This lets you get the settings right without risking any damage.

- Set the laser head position so the beam stays at the ideal distance and angle to the surface. I find that small adjustments here help me get an even result.

- Run a short test scan and watch the surface and the area around it. If I see signs of overheating or the material changing color, I pause and fix the issue.

- If everything looks good, I start cleaning with a clear plan. Move the laser in smooth, overlapping passes, and do not stay in one area for too long. This prevents accidental burns and makes the finish look even.

- For tough residue, you might need to repeat the process or add a little more power. My rule is to do this in small, careful steps.

Efficiency Tips for Different Jobs

- For big jobs, like on cars or industrial parts, I break the work into sections. In my experience, overlapping the sections gives you a cleaner, more professional result.

- When working on sensitive things like art, antiques, or electronics, I double-check that the power is on the lowest effective setting. Being precise here saves you time and money on potential restoration work.

Following my advice will help you clean more efficiently while protecting the surfaces and your team. In my experience, a careful setup and a steady process are the secrets to getting safe, high-quality results every time.

My Guide to Laser Cleaner Maintenance and Troubleshooting

A laser rust cleaning machine is a big purchase. Based on my experience, doing upkeep and fixing issues fast is key to protecting your investment. Here’s how I maintain my gear to avoid costly repairs.

My Essential Maintenance Steps

Clean the Optics Often

The quality of the laser beam depends on clean optics. I always make time to wipe down the lenses and mirrors using the right cleaning materials. Any dust or smudges can reduce cleaning power and damage surfaces.

Inspect All Connections

Every few days, I check every cable, connector, and pipe. I check all the lines: electrical, cooling, and air. I’ve learned that a loose plug can hurt performance. A cracked hose could even be dangerous.

Update the Control Software

I always keep the control software current. I find that updated firmware gives me new features. It also fixes bugs that can cause problems during a job.

Check and Maintain Cooling Systems

Overheating is a major enemy of laser machines. I make it a point to monitor coolant levels and flow. If your system uses fans or air cooling, make sure vents are clear and moving parts are dust-free.

How I Fix Common Laser Cleaner Problems

Uneven Cleaning Results

If you see streaks or spots left behind, I recommend checking the focus first. Adjust the focus and laser power bit by bit until you get an even effect across the whole surface.

Machine Overheating

I’ve noticed this happens a lot on longer jobs. My first step is to check the cooling system. I look at the coolant level, the pump, and check for blocked pipes. In my experience, fixing a small leak or adding coolant solves the problem.

Laser Power Fluctuations

Sudden drops or jumps in power often point to loose or faulty connections. I check each electrical cable one by one. I feel for any warm spots or loose connections.

My Pro Advice

From my experience, doing preventive checks is always better than dealing with an emergency repair. I’ve found taking a little time for checkups saves a lot of money and avoids stressful downtime. If you’re unsure, my advice is to stick to the manufacturer’s maintenance schedule. I’ve found it’s the best way to get years of service from your laser cleaner.

Cost Considerations for Laser Cleaners

If you’re buying a cleaning laser machine, you must understand the costs involved. A machine’s price depends on its features, type, and power. From my experience, you should look at the total cost, not just the price you pay today.

Key Factors That Affect Laser Cleaner Pricing

Type of Machine:

– Continuous Wave (CW) lasers are at the lower end of the price range. I find they are best for simple, heavy-duty jobs.

– Pulsed lasers offer more versatility and precision. For that extra flexibility, I’ve seen that you will pay a higher price.

Power Rating: More wattage gives you faster cleaning but also costs more. In my opinion, if you have large and tough jobs, you should expect to pay more upfront for that power.

Automation Options: You can add robots or CNC integration to make the cleaning process almost automatic. Be aware that these advanced features will increase your total cost.

Typical Price Range in the U.S.: I’ve seen commercial laser cleaning machines cost from $15,000 to over $100,000. The final price will depend on the power, type, and automation you select.

Ongoing Operating Costs

A big advantage of laser cleaning is its low running cost, as it’s far cheaper to operate than methods using chemicals or abrasives. There’s no need for ongoing solvents or abrasives, and the main expenses are simply electricity and basic maintenance.

My Buyer Tip: Look Beyond the Sticker Price

I suggest you look past the initial purchase price. Think about the savings over the machine’s entire life:

- Labor: You will need less manual work.

- Materials: You won’t have to keep ordering chemicals or pads.

- Compliance: I find it’s easier to meet safety and environmental rules.

Based on my experience, the machine’s true value becomes clear over time. You see it in the money you save over years of use, not just the initial cost.

Summary

Laser cleaning isn’t just about efficiency—it’s about saving costs, protecting valuable materials, and opening up new possibilities for your business. With the right machine, you’ll discover just how easy it is to achieve professional results in less time and with far less effort. If you’re ready to take the first step into this powerful technology, now is the perfect time to explore the laser cleaner that fits your needs and start transforming the way you work. Reach out to us today to find the best solution for your business—we’d love to hear from you!