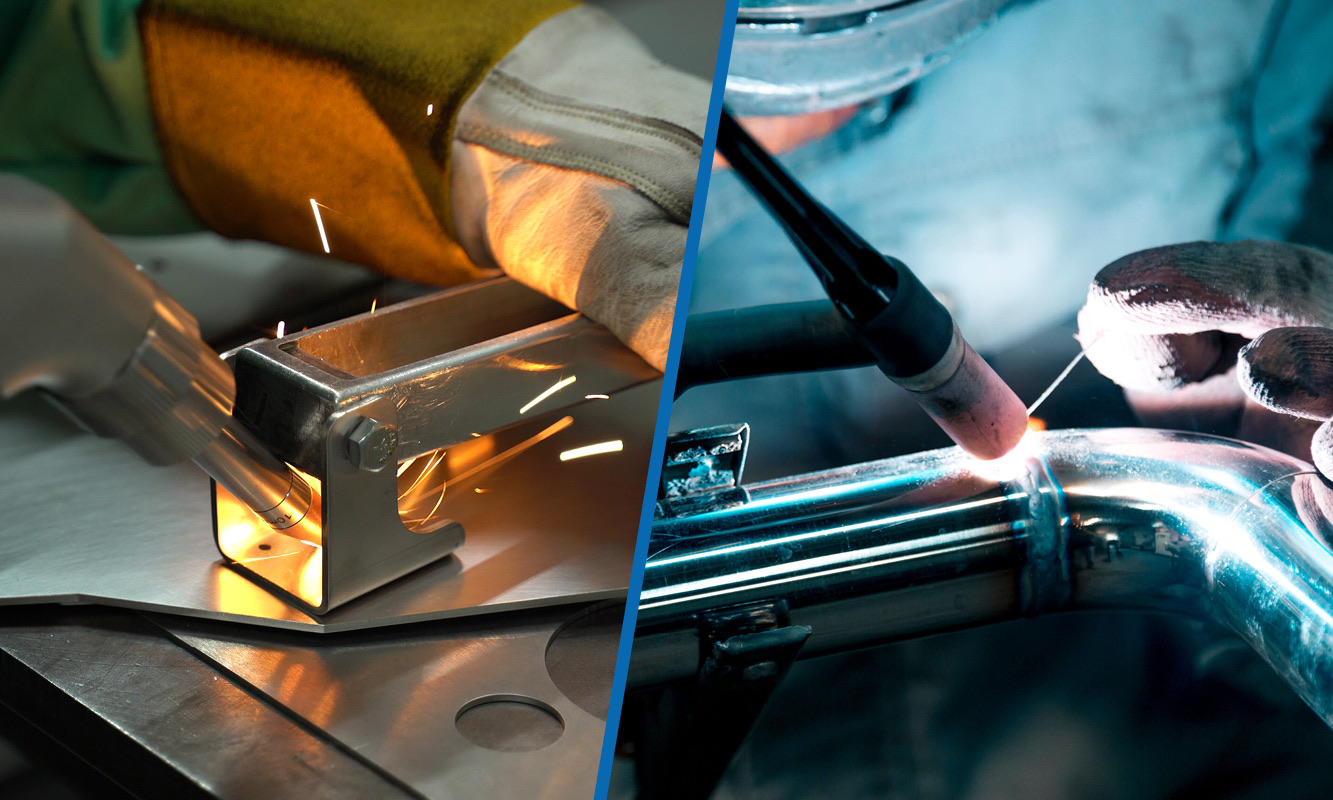

In the manufacturing sector, welding is the critical link that transforms ideas into finished products. Selecting the appropriate welding equipment directly impacts product quality, production efficiency, and profit margins. Among numerous welding technologies, TIG and laser welding are two processes that have attracted significant attention. While traditional TIG welding, known for its exceptional versatility, has become a workshop standard, laser welding represents the future of joining technology with its unparalleled speed and precision.

So, which technology better suits your workshop? This article will conduct an in-depth comparison of both equipment types’ working principles, advantages, and limitations, with particular emphasis on analyzing why laser welding is increasingly becoming the preferred solution for modern workshops pursuing operational excellence.

Welding Technology Comparison Analysis

| Comparison Item | TIG Welder | Laser Welder |

|---|---|---|

| Welding Speed | Slow | Extremely Fast (3-10x faster) |

| Operation Difficulty | High skill requirement, relies on manual experience | Easy to learn, 30-minute mastery |

| Weld Quality | Wide weld seams, prone to deformation | Fine, aesthetically pleasing welds, minimal deformation |

| Suitable Material Thickness | 1-5 mm | 0.1-5 mm, superior for ultra-thin sheets |

| Equipment Cost | Low | High, but fast ROI |

| Application Scenarios | Repair shops, small workshops, auto repair, general metalworking | Sheet metal workshops, door/window manufacturers, kitchenware factories, hardware factories, jewelry welding, startup workshops, factory automation upgrades |

TIG Welding: The Artisan’s Choice of Skillful Craftsmanship

TIG welding is a process that uses a non-consumable tungsten electrode and an inert shielding gas (typically argon) to create an electric arc for welding. The operator holds the torch in one hand and a filler wire in the other, manually feeding it into the weld pool. This process demands exceptional hand-eye coordination, a steady hand, and precise control over heat input. The primary advantage of TIG welding lies in its exceptional versatility, capable of welding a wide variety of metals and alloys, including stainless steel, aluminum, magnesium, copper, titanium, and even dissimilar metals. This broad applicability makes it ideal for repair shops, prototyping, and low-volume custom work. Furthermore, it can produce extremely clean, aesthetically pleasing, spatter-free welds, and its precise heat control allows for challenging operations like root passes and precision welds. Additionally, the initial investment for an entry-level TIG machine is significantly lower than that of an industrial laser welding system, making it more accessible for small workshops or hobbyists on a budget.

However, TIG welding has notable limitations. It is a relatively slow process; being a manual wire-feeding process with relatively low thermal efficiency, TIG is one of the slowest of all common welding processes, which is a major bottleneck in high-productivity applications. More critically, the process is highly dependent on operator skill. Training a proficient TIG welder requires significant time and investment, and the operator’s skill level directly and significantly impacts weld quality and consistency. Another key issue is its large Heat-Affected Zone (HAZ). The TIG arc is relatively diffuse, causing heat to spread widely into the base material. This can lead to distortion, discoloration in thin sheets, and even alterations in the material’s mechanical properties. Due to the heavy reliance on manual operation, maintaining perfectly consistent weld quality over long periods is also challenging and prone to human error.

Laser Welding Machine: The Efficiency Engine of Modern Manufacturing

Laser welding represents a paradigm shift in joining technology. It utilizes a highly focused laser beam with high energy density as the heat source. When the laser beam strikes the material surface, the material rapidly melts and even vaporizes, forming a “keyhole” with a high depth-to-width ratio. The laser energy travels through this keyhole deep into the material, enabling deep penetration welding. This process is typically highly automated, controlled via robotic arms or CNC systems. The core advantages of laser welding are multifaceted. It offers extremely high welding speeds, achieving several meters per minute, far surpassing TIG welding. This dramatically increases production throughput and shortens product lead times. More importantly, it provides unmatched precision and a minimal Heat-Affected Zone (HAZ). The laser beam can be focused to a very small spot, enabling exceptionally fine welds. The concentrated heat source means very low total heat input and an extremely small HAZ. This brings revolutionary benefits such as minimized workpiece distortion, preservation of the material’s original properties, and good weldability on reflective materials.

Furthermore, laser welding systems are inherently designed for automation. Once parameters are set, a robot can repeat the exact same weld path indefinitely, ensuring every single product has identical, top-tier quality. This significantly reduces dependence on operator skill and guarantees absolute reliability in mass production. As a non-contact process, the laser head does not contact the workpiece, eliminating tool wear. This allows it to weld in hard-to-reach areas and facilitates integration into flexible manufacturing systems. For thicker materials, lasers can achieve high aspect ratio deep penetration welds in a single pass, whereas TIG would require multiple, less efficient passes. Although the initial investment for a laser welding system is higher, its advantages in speed, consistency, reduced rework, and lower long-term labor costs offer a superior Total Cost of Ownership (TCO) for high-volume production.

Welding Technology Selection Guide

Based on the above analysis, both technologies have their optimal application scenarios. TIG welders are ideal for small-batch, high-variety production, particularly suitable for workshops with limited budgets mainly engaged in repair and prototyping work, or when welding joints require technician experience to compensate for loose fit-up tolerance.

In comparison, laser welders are more suitable for medium to large-volume repetitive welding tasks, when production speed and efficiency become core competitive advantages, such as in automotive and consumer electronics supply chains. If your products involve thin-gauge materials, precision components, or have strict requirements for product appearance and deformation control, laser welders can provide perfect solutions. Meanwhile, for enterprises seeking to reduce dependence on highly skilled welders, enhance production line stability through automation, and focus on long-term comprehensive costs rather than just initial investment, laser welding represents the optimal choice.