In today’s competitive manufacturing landscape, your choice of aluminum welding process directly impacts production efficiency and market competitiveness. While traditional TIG welding relies on manual expertise, modern laser welding technology delivers a revolutionary breakthrough—offering multi-fold increases in speed, millimeter-level precision, and automated intelligence that elevate both productivity and weld quality to new heights. This article provides a clear comparison of the core advantages of both processes, helping you make the most informed decision to enhance your output and profitability.

| Feature | Laser Welding | TIG Welding |

| Speed | 2–20 m/min | 0.1–0.8 m/min |

| Heat-Affected Zone | Very narrow | Very wide |

| Thickness Range | 0.02–8 mm | 3–6 mm |

| Porosity Rate | ≤0.1% | 1–3% |

| Training Time | 5–10 minutes (basic operation) | 6–18 months (certification) |

| Operating Cost | $0.18/ft | $0.85/ft |

| Automation Rate | 95% success | 40% success |

| First-Pass Success | 98% | 45% |

Welding Speed: The Productivity Divide

The speed advantage of laser welding is transformative. While TIG welding progresses at 0.1–0.8 meters per minute, laser welding operates at 2–20 meters per minute. This isn’t just a marginal gain—it translates to a 3–10X productivity increase in real-world applications.

Consider a medical device manufacturer: laser welding reduced the pacemaker housing weld time from 18 minutes (TIG) to just 73 seconds, yielding annual savings of $1.2 million. The efficiency gap widens further when accounting for preparation and post-processing. Laser welding eliminates time-consuming steps like spatter removal, grinding, and straightening, which are inherent to TIG. For aerospace-grade aluminum, TIG labor costs can reach $47 per foot, a figure dramatically reduced by laser automation.

Application Guide:

- Choose Laser Welding for: High-volume runs, robotic cells, thin-walled assemblies, and automated CNC workflows.

- Choose TIG Welding for: Specialized repairs, variable geometry projects, or custom work where manual precision outweighs the need for speed.

Heat Control in Welding: Precision vs. Post-Processing

The precision of handheld laser welding machines stems from their minimal heat input—just 50–200 J/mm versus TIG’s 500–1500 J/mm.This 10x reduction in thermal energy dramatically controls part distortion. On a 1-meter aluminum sheet, laser welds keep distortion at or below 0.1 mm, while TIG typically causes 1–3 mm of warping. This difference often eliminates costly post-weld straightening.

The heat-affected zone (HAZ) reveals why. Laser welding concentrates energy into a deep, narrow zone, leaving surrounding material largely unaffected. TIG welding spreads heat widely, creating a broader, shallower HAZ that heightens the risk of overheating, especially in sensitive aluminum alloys.

These thermal characteristics directly impact cost and quality. One manufacturer saved $420 per part by eliminating distortion-related rework with laser welding, achieving a defect rate of just 0.8% compared to TIG’s 5.7%.

Application Guide:

- Choose Laser Welding for: Thin panels (<3mm), tight-tolerance assemblies, parts that cannot be straightened, and high-volume production.

- Choose TIG Welding for: Thick sections where some movement is acceptable, or jobs where post-weld machining is already planned.

Welding Depth and Strength: The Durability Connection

Material thickness directly governs weld strength. Laser welding machine excels from 0.02mm to 8mm thicknesses, while TIG performs best within 3-6mm ranges. As thickness increases, laser’s superiority becomes more pronounced. On 5mm aluminum, laser achieves 20% higher tensile strength than TIG due to deeper penetration and faster solidification.

Grain structure analysis reveals the quality foundation: TIG produces fine-grained welds offering excellent flexibility, while laser creates uniform, robust grain structures. This explains laser’s exceptional quality metrics—<0.1% porosity versus TIG’s 1-3%, and dramatically lower defect rates (0.8% vs 5.7%).

Application Guide:

-

Choose Laser Welding for: Critical joints requiring maximum strength, applications demanding minimal porosity, and complex positional welding.

-

Choose TIG Welding for: Thin materials (<3mm) where fine grain flexibility is essential, or specialized repair work.

Welding Precision and Appearance: Repeatability vs. Artistry

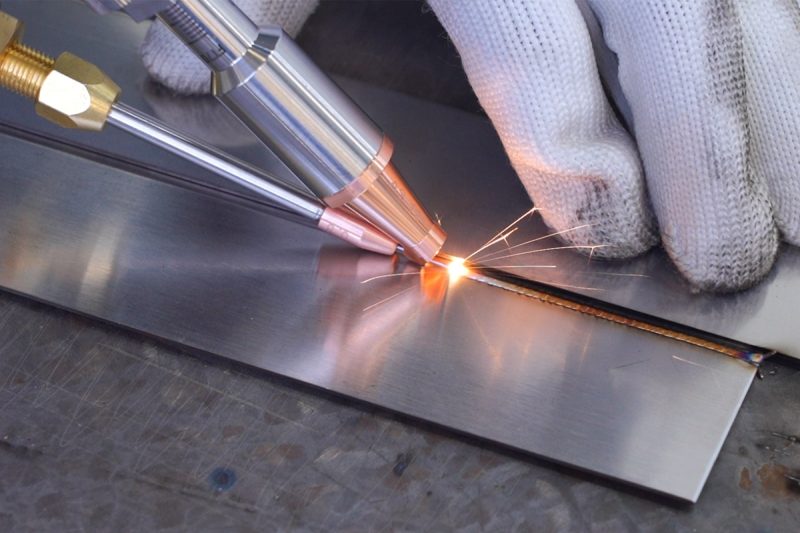

Precision defines weld integrity.The 3 in 1 laser welding machine achieves pinpoint accuracy with a 0.2-2.0mm focus, ensuring consistent results, while TIG’s broader arc requires operator skill for precision. In production, laser’s automated repeatability guarantees each weld matches the last, whereas TIG outcomes depend on welder expertise.

While skilled MIG welders can produce decorative fish-scale beads, this requires extensive training. Laser welding allows novices to create smooth, visually flawless welds with minimal distortion—ideal for visible, high-appearance joints.

Microstructurally, laser welding forms a fine-grained, high-strength structure, while MIG welding’s slower cooling yields coarser grains with better ductility.

Application Guide:

-

Choose Laser Welding for: Automated production with ±0.1mm tolerance, hermetic sealing, and space-constrained welds.

-

Choose TIG Welding for: Visible seams requiring show-quality finish, custom work needing human adjustment, or maximum ductility needs.

Welding Material Compatibility: Choosing the Right Process

Material thickness fundamentally directs process selection. Laser welding excels with thin aluminum (0.02-8mm), delivering high precision, while TIG is most practical for moderate to thick sections (3-12mm). For ultra-thin parts below 0.5mm, TIG risks burn-through, whereas laser consistently handles foil-thin materials.

Single-pass capacity highlights this divide: fiber lasers penetrate up to 4mm in one pass, while TIG requires multiple passes beyond 6mm, increasing time and heat input.

Beyond aluminum, laser offers superior material versatility. It effectively joins diverse metals—including aluminum to copper—thanks to precise heat control. TIG performs well with common metals but struggles with dissimilar material combinations.

Application Guide:

-

Choose Laser Welding for: Thin aluminum (<6mm), multi-metal joints, and precision thin-wall applications.

-

Choose TIG Welding for: Thicker aluminum sections (>6mm), heavy structural work, or when equipment cost is prohibitive.

Welding Shielding Gas: Efficiency and Cost Balance

Shielding gas requirements mark a clear distinction between processes. TIG welding demands high gas flows—typically ≥99.997% argon at 15 L/min—to protect its wide arc and weld pool. Laser welding, with its concentrated heat zone, operates effectively at significantly lower flow rates.

This operational difference impacts both process stability and cost. Laser welding’s smaller, quickly solidifying weld pool resists contamination even in imperfect conditions, while TIG is vulnerable to drafts and turbulence. In cost terms, laser averages $0.18 per foot (lower gas, no filler) versus TIG’s $0.85 per foot.

Application Guide:

-

Choose Laser Welding for: High-volume production where gas efficiency and cost control are priorities, particularly for thin materials.

-

Choose TIG Welding for: Thick sections requiring intensive gas coverage, or in workshops where manual gas control aligns with existing operator skills.

Cost & Accessibility: Professional Welding, Simplified

A breakthrough in affordability: our handheld laser welders start at just $2,500, putting industrial-grade technology within reach of every workshop. While professional TIG systems still cost $2,000, laser now offers superior capability at comparable entry cost. More importantly, laser’s operational efficiency creates immediate savings—at $0.18 per foot versus TIG’s $0.85, you achieve 79% lower running costs from day one.

What truly sets our solution apart is unmatched accessibility. With our intuitive system, operators can learn basic welding in 5-10 minutes, while professional TIG proficiency still requires 6-18 months of dedicated training. This revolution in learning curve means any team member can produce consistent, high-quality welds with minimal guidance.

Designed for modern workflows, our laser systems provide plug-and-play operation that easily transitions between manual use and automated integration.

Application Guide:

-

Choose Laser Welding for: Instant operational readiness, maximized cost efficiency, and seamless scalability from manual to automated production.

-

Choose TIG Welding for: Budgets strictly under $2,000, workshops with existing TIG-certified staff, or highly specialized manual applications.

Welding Automation: Precision and Efficiency in Robotics

Automation adaptability critically distinguishes these two processes. The handheld laser welder, with its portable mobility, integrates seamlessly into diverse production environments. When coupled with automated systems, it achieves an integration success rate exceeding 95%. Its highly stable laser energy output per pulse makes it ideally suited for repetitive robotic tasks, ensuring every weld is precise and consistent in high-volume production. In contrast, TIG welding often struggles with an integration rate below 40% due to challenges with arc stability and positional control.

Performance metrics show a clear advantage: laser automated lines can achieve welding speeds over 8 times faster than conventional methods in complex positions, with a first-pass success rate above 98%. Its fume-free, low-spatter operation further enables unmanned, clean production. Under similar conditions, TIG welding typically achieves only about a 45% first-pass success rate and demands stricter environmental controls.

Application Guide:

-

Choose Laser Automation for: Factories requiring high-precision mass production and forward automation upgrades, as well as processing scenarios with minimal post-processing needs. The flexibility of handheld laser welders also makes them easily adaptable to flexible production lines with high-mix, low-volume outputs.

-

Choose TIG Welding for: Low-volume custom work requiring human adaptability and adjustment, or workshops with established manual welding expertise.

Conclusion

Your choice today shapes tomorrow’s success. While TIG welding retains value in certain custom applications, laser welding unquestionably represents the future of aluminum processing. It not only increases welding speed by 3–10 times but also significantly reduces thermal distortion and post-processing costs, delivering near-perfect weld consistency. Leading manufacturers are already adopting laser welding technology to stay ahead.