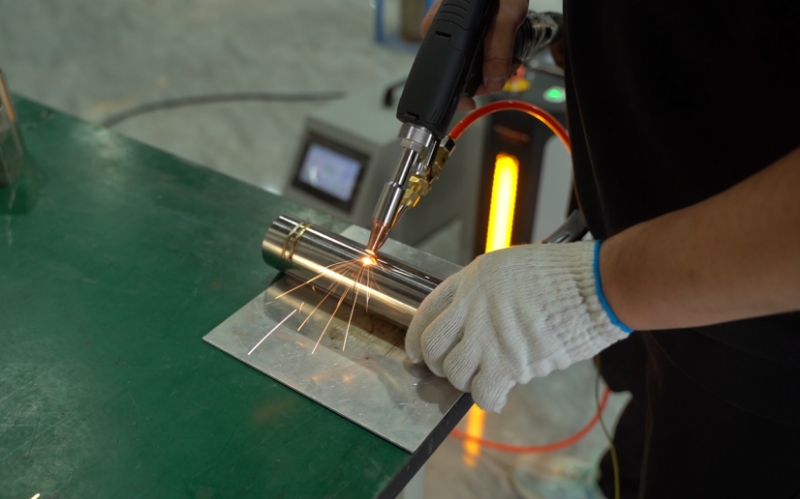

Sparks fly, metal fuses, and precision matters. If you’re chasing flawless welds and unstoppable power, a 1500W laser welding machine is your ultimate tool. In this countdown, we reveal the top 10 brands in the USA that are turning raw energy into perfect seams—faster, cleaner, and stronger than ever.

Top 10 1500W Laser Welding Machine Brands in USA At A Glance

If you’re looking for powerful 1500W laser welding machines, I think these U.S. brands are excellent choices. They are known for their quality, new ideas, and how well they work. Let me give you a look at some top options, their popular models, and what makes them special.

- MaxWave

- IPG

- TRUMPF

- Coherent

- LaserStar

- Lincoln

- Jenoptik

- Alpha

- Precitec

- Panasonic

Top 10 Laser Welding Machine Brands in the USA

If you’re searching for top 1500W laser welder, I’ve found the U.S. market has several excellent brands. From my experience, these brands are at the forefront of technology and performance. People know these companies for their dependable machines, new ideas, and solid customer support.

1. MaxWave Laser

MaxWave Laser is a manufacturer specializing in laser welding, cleaning, and marking solutions, headquartered in China. Committed to delivering high-performance and user-friendly laser equipment to global customers, MaxWave offers a 1500W handheld laser welding machine featuring high-frequency pulsed mode, a flexible 15-meter cable, and storage for up to 74 process parameters. Widely used in metal fabrication, equipment repair, and industrial manufacturing, MaxWave Laser is trusted by entrepreneurs and industrial clients alike for its innovative design, ease of use, and 24/7 technical support.

2. IPG Photonics – Leading Fiber Laser Technology

IPG Photonics, located in Oxford, Massachusetts, really makes a mark with its advanced fiber laser welding machines. In my opinion, their 1500W models, like the LightWELD series, provide very precise and stable welds. These work on different materials, including stainless steel, carbon steel, and aluminum. Many U.S. manufacturing shops pick IPG. I believe this is due to their machines’ reliable performance and quick after-sales support. Automotive, aerospace, and electronics industries use their energy-efficient machines.

3. TRUMPF Inc. – TruLaser Series for High-Precision Fabrication

TRUMPF, from Farmington, Connecticut, is a big name in laser manufacturing, and I quite agree. Their TruLaser and TruFiber series include 1500W models which, in my experience, get high marks for industrial automation and making items with great precision. I think TRUMPF is special because of its smart automatic settings and adjustable laser power. Many aerospace companies in the USA use these for welding key components. Customers really seem to value the brand’s ability to integrate with other systems.

4. Coherent Inc. – Precision Welding for Specialized Industries

Coherent Inc. in Santa Clara, California, provides high-precision 1500W laser welding machines. I’ve noticed companies often pick these machines for making medical devices and for electronics work. This is likely due to their advanced beam control and software that I find easy to use. Their flexible system setups work well for both research environments and large industrial operations. I also hear that Coherent’s machines are good for quick, precise welding, especially when the job needs careful attention to small details.

5. LaserStar Technologies – Portability and Ease of Use

LaserStar Technologies in Rhode Island focuses on small, handheld, and desktop laser welding machines. I see their 1500W units used a lot for jewelry repair, dental tasks, and complex metalwork. Users in North America often say these machines are easy to manage and learn. I think the U.S.-based manufacturing and training centers really help with customer happiness and make the machines more accessible.

6. Lincoln Electric – Industrial-Grade Solutions for Heavy Manufacturing

Lincoln Electric, based in Cleveland, Ohio, sells 1500W fiber laser systems. I recommend these for tough factory settings and large automated processes. Automotive suppliers and metal fabricators often pick their laser welding gear. I believe it’s because they want to improve productivity and keep machine downtime to a minimum. These machines easily connect with existing robotic systems. Plus, they are built strong to last on busy factory floors.

7. Jenoptik North America

Jenoptik provides automation-ready laser welding solutions from facilities in Jupiter, Florida, and Rochester Hills, Michigan. Their machines are widely used in automotive component welding due to their precision and scalability.

8. Alpha Laser

Founded in 1994 (Meadville, Pennsylvania), Alpha Laser offers portable handheld and industrial laser welding solutions, with a focus on ease of use, safety, and flexibility for repair and manufacturing environments.

9. Precitec Inc.

Operating since 1971 (Wixom, Michigan), Precitec is recognized for integrated laser processing heads and automation-friendly systems for high-precision, high-speed welding in aerospace and electronics.

10. Panasonic Factory Solutions Company of America

Based in Rolling Meadows, Illinois, this division of Panasonic offers energy-efficient laser welding machines equipped with IoT support and data analytics for real-time performance tracking and predictive maintenance, making them ideal for smart factory integrations.

Key Comparison Factors

- Common Uses: I see them in automotive, aerospace, electronics, jewelry, and medical device industries.

- Tech Advantages: I look for readiness for automation, how easy they are to move, and precise beam control.

- What Customers Experience: Fast delivery is great. Local support centers, training materials, and dependable after-sales service are also important to me.

- Price Example: The MaxWave Laser MW-HW1500 starts around $3,800. I think this makes it attractive for smaller businesses that need affordable automatic welding.

From my perspective, these ten brands are the top names in 1500W laser welding technology in America. Each provides unique benefits in quality, flexibility, and customer value. I think this helps manufacturers achieve exact and efficient work across many different uses.

Key Models and Features of 1500W Laser Welding Machines

In my experience, the best 1500W laser welder in the USA offer a great mix of power, efficiency, and flexibility. These qualities make them suitable for many professional uses. Let’s explore some key models. I’ll cover their main specs, prices, and the standout features. I find these features are why American manufacturers and metal fabrication pros like them.

Key Models and Their Specifications

MaxWave 3-in-1 Laser Welder

This versatile device supports welding, cutting, and cleaning, making it ideal for multiple applications. Its durable design and 10–15 meter fiber cable provide great mobility in larger workshop settings. Priced at $4,399, it offers strong value for smaller shops or users seeking automation without a high upfront investment.

IPG Photonics LightWELD XC 3-in-1 Laser Welder

The LightWELD XC features an advanced industrial-grade cooling system, adjustable power output (10–100%), and multiple safety mechanisms such as an emergency stop, multi-position trigger, and laser safety interlocks. Its rugged, compact design is ideal for use in automotive repair, equipment manufacturing, and precision metalworking.

TRUMPF TruFiber fiber laser systems

The TruFiber series laser welding machine from TRUMPF represents the high standard of German industrial laser technology. Designed for high-precision welding and fine processing, TruFiber offers stable 1500W continuous output and excellent beam quality, making it ideal for applications in electronics, medical devices, and other precision-focused industries.

Coherent 1500W Handheld Laser Welding Machine

Coherent’s 1500W handheld laser welding machine delivers high beam quality and stable output with a water-cooled system for reliable long-term use. It welds stainless steel, carbon steel, and aluminum up to 4–5 mm thick, supports continuous and pulsed modes, and features an intuitive interface with remote diagnostics. Designed for high-precision, repeatable welding in demanding industrial and automated settings.

Performance, Portability, and Flexibility

From what I’ve seen, these aspects are crucial:

Welding speed: Top models can weld very fast, up to 120 mm/s. They can also handle metal plates up to 6 mm thick. This varies by machine and how you use it.

Portability: Many laser welding machines are compact. They often have casters. This makes it easy to move them in busy shops or to different job sites.

Operational flexibility: I find that many machines have pre-set programs. You can also customize programs. This helps switch easily between materials or tasks, which cuts down setup time.

Accessories and Support: Standard features often include air assist (using nitrogen, for example). You also get multiple welding gun styles and nozzles that are easy to swap. Extended warranty options are also common, like MaxWave’s 2-year warranty. I think these are important considerations.

Price Overview for Popular Models

Here’s a look at some prices I’ve noted:

- MaxWave 3-in-1 Laser Welder: $4,399

- IPG Photonics LightWELD XC 3-in-1 Laser Welder: $27,700–$28,000

- Raycus 1500W Handheld Laser Welder: $5,999

- Advanced system price range: For premium models that are multi-functional or air-cooled, I see prices ranging from $15,000 to $25,000.

Material Compatibility and Application Range

From my experience, all top laser welding machine brands are versatile enough to handle various metals—like stainless steel, carbon steel, aluminum, and galvanized sheet. They’re widely used across different applications, from sheet metal work and cabinet making to home metal projects, elevator manufacturing, custom rack fabrication, and professional repair jobs.

What Users Say & How They Benefit

Here’s what I’ve heard from users:

- MaxWave: I see this machine is designed to be flexible for welding, cutting, and cleaning. It’s popular in small workshops that need one machine for different tasks.

- LaserStar iWeld Benchtop & Industrial Models: Users say it’s faster and more efficient than old MIG/TIG welding methods in U.S. shops. They also praise its great versatility.

- Bescutter: People know this one for making very fine weld seams. It performs steadily and reliably in tough sheet metal and fabrication settings.

In my opinion, these models and their features really define what’s good in terms of working flexibility, value for money, and new ideas in the American laser welding machine market.

Summary

I’ve looked at many 1500W laser welding machines. I think to choose the right one, you first need to understand your specific needs. Your budget is also a key factor. For instance, if you are a small shop, I suggest looking at MaxWave’s affordable solutions to get started. If you are a large manufacturer, TRUMPF provides systems for very exact work. Based on what I see, the American market offers excellent choices for both. From my own work, I’ve learned that investing in quality laser welding technology is more than just getting a new machine. I feel it changes how you do your job. It also helps you find new opportunities in metalworking. For more details about handheld laser welding machine or to get a quote, contact us today!