I’ve noticed many factories are changing their old welding methods. Have you wondered why? I think laser welding is really changing manufacturing. It makes the process faster and cleaner. In my opinion, it’s also much better for the environment, which I find impressive. Based on my experience, it’s more than just achieving sharper welds or saving on costs.

I believe the significant environmental benefits are what truly capture people’s attention. I like the idea of cleaner factories and products that last longer—that sounds great, doesn’t it? But I often wonder, what’s the one aspect most people might still overlook?

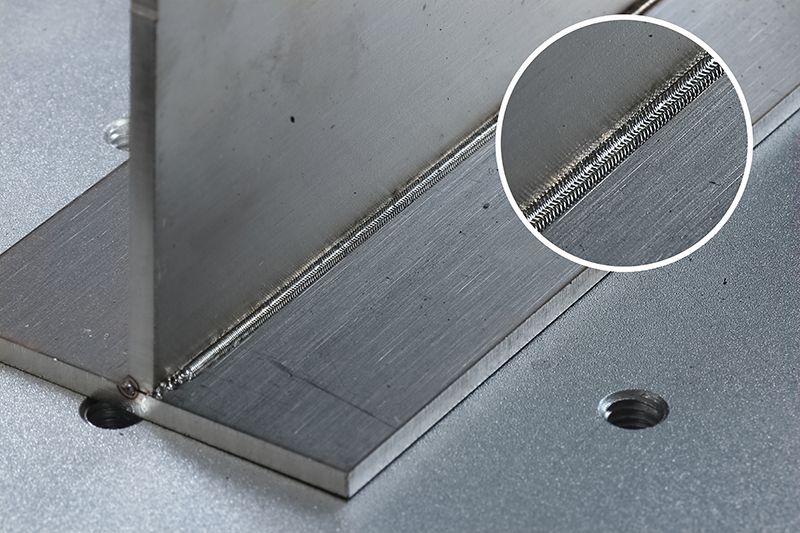

Exceptional Precision and Accuracy with Laser Welding Machines

Laser welding machines offer amazing precision. I’ve seen them work with error ranges under 0.1 millimeters. They can even achieve welding at the micrometer level. This specific control is vital. For example, in aerospace and medical device industries, every fraction of a millimeter matters a great deal.

Key Benefits of Laser Welding Precision

Better Joint Precision: A study from the Manufacturing Technology Institute shows laser welding improves joint precision by up to 30%, helping maintain exact tolerances and reduce errors.

Pinpoint Accurate Positioning: The focused laser beam allows precise targeting, ensuring accurate, consistent welds—even for tiny joints and delicate electronics.

Steady Weld Quality: Automated control delivers uniform welds every time, minimizing flaws and reducing dependence on operator skill or machine stability.

Better Welds, Lasting Longer with Laser Welding Machines

In my experience, laser welding machine gives excellent weld quality. Products also last longer in factories. I think this strong performance is why many industries now use it more. These industries are automotive, aerospace, electronics, and jewelry making.

Key Data Shows Why It’s Better

Stronger Joints: I’ve seen laser-welded joints be up to 25% stronger (tensile strength) than old welding methods. This means products last longer. You also save money on upkeep.

Minimal Warping: This process uses controlled heat. I like that it means less material warping and stress. So, welded joints are stronger. They hold up well under repeated stress.

Fewer Errors with Small Assemblies: In electronics, I’ve found that precise laser welding cuts errors in assembly by 15%. This happens because each joint is reliable.

In my view, laser welding machine makes strong, durable, top-quality welds every time. Data and real-world results show its strengths: stronger joints, fewer errors, and faster production. It also performs very well in key applications.

Faster Production and More Efficiency with Laser Welding Machines

Laser welding boosts manufacturing efficiency, operating 4–5 times faster than TIG or MIG methods. With just 2–3 kW of power, it can weld thin metals at 5–10 m/min—making the productivity gains clear.

What Makes Laser Welding Efficient? I’ll show you some key points.

Joints Form Faster: Laser welding machine uses focused energy. This makes small, precise weld pools. Joints form fast. This means you get continuous operation. I see fewer stops or delays on the production line.

Works Well for Thin and Thick Materials: Laser welding excels on thin sheets with high speed, and remains efficient on thick plates by increasing power, even if speed slightly decreases.

Less Time and Money Spent on Processing: Handheld fiber laser welding machine use 80–90% less energy than TIG welding and reduce processing costs by around 30%, thanks to faster work and minimal finishing.

From my perspective, these benefits make laser welding an excellent option. I suggest it for modern manufacturers. It helps them make more, keep quality high, and manage production costs.

Minimal Thermal Distortion in Laser Welding: Higher Quality, Less Waste

I find that a key benefit of laser welding machines for industrial manufacturing is minimal thermal distortion. From my experience, this greatly improves overall product quality, speed, and material savings.

How Laser Welding Reduces Distortion

Focused Energy: Laser welding delivers tightly controlled energy through a beam just millimeters wide, minimizing heat spread and protecting part integrity.

Tiny Heat-Affected Zone (HAZ): Laser welding concentrates heat in a small area, reducing warping and preserving material shape—leading to better part fit and appearance.

Minimal thermal distortion from laser welding means you get higher product quality. It also leads to more efficient manufacturing and big cost savings. I believe this is why laser welding machine is a top choice for modern industry.

Cutting Down Waste: How Laser Welding Boosts Efficiency and Helps Our Planet

I find laser welding machine is excellent for greatly reducing material waste in factories. Because this process is so accurate and controls energy well, I see manufacturers use less material than with old welding ways.

My Insights: How Laser Welding Cuts Waste

Almost No Spatter or Extra Filler: Laser welding is non-contact and precise, using only the needed material—no filler or spatter, reducing metal waste.

Using Materials Exactly: The focused beam avoids overlap and errors. AutoMaster Inc. cut material waste by 20% after switching to laser welding.

Cleaner Welds, So Less Fixing Later: Laser welds are cleaner and need less post-processing, saving time, materials, and reducing scrap.

Fewer Mistakes, Stronger Products: Greater precision leads to better fits, fewer errors, and longer-lasting parts—cutting waste throughout the product’s life.

Based on my experience, cutting down waste is a big reason why so many modern factories like laser welding. I recommend it because they care about our planet, saving money, and doing excellent work. I’ve seen firsthand how it supports these important goals.

Lower Energy Consumption: Laser Welding’s Efficiency Advantage

I find laser welding machines to be very energy efficient. They use much less energy than older welding methods. How do they do it? The laser beam focuses energy right on the weld spot. This means almost no energy is wasted, and less heat spreads to other areas.

How Laser Welding Saves Energy

- Because the energy is very focused, no extra material gets heated. Energy goes just to the seam. So, little energy escapes into the air around it.

- You also don’t need filler wires or rods. This means using less energy on supplies. It also means less time spent fixing or finishing the weld.

- Unlike electron beam welding, laser welding doesn’t need a vacuum chamber that uses a lot of energy. This saves on running costs and helps the environment, in my opinion.

Industry Examples and Market Trends

Many medium-sized factories that have switched from TIG to laser welding report over 80% savings in energy costs and significant reductions in carbon emissions. This shift reflects a broader trend, with fiber lasers accounting for around 38% of the market share in 2023—driven largely by their superior energy efficiency.

Switching to laser welding gives factories a major edge with lower energy use, reduced costs, and greener operations. I highly recommend it for any industry aiming to save energy.

Better Automation

I find that laser welding machines really improve industrial automation. They give manufacturers smarter, more connected production ways. A big plus for making lots of things, in my experience, is how they can weld with little human help.

Easy System Hook-ups

I’ve seen modern laser welding machines link up with automated production lines, robotic arms, and CNC systems. I believe this smooth connection leads to: – Consistent welds every time. – Lower labor costs because less direct human work is needed. – A big drop in human error risks, mainly for large or tricky jobs. I think this is a key benefit.

Smart Controls and Easy Changes

I notice today’s laser welding machines have modern touch screens and smart control systems. This means operators can program and change settings quickly. Some settings they can adjust include: – Welding speed – Pinpoint accuracy – Power levels, I think this adaptability is great because factories can switch to new product designs or materials fast, without difficult setup changes.

Joining Different Materials

I’ve seen that laser welding machines are great for joining many types of materials. This gives manufacturers more options than old welding methods. In my experience, this flexibility is a big reason many industries now choose laser welding for making their products.

What Materials Can Be Welded?

I’ve noticed laser welding works great with many materials.

– Metals: Laser welding works with stainless steel, aluminum, carbon steel, titanium, nickel alloys—even reflective or delicate metals like copper, ideal for electronics and automotive use.

– Different Metals: It can join dissimilar metals, like aluminum to steel, with strong, reliable welds—something older methods often struggle with.

– Different Thicknesses: Laser welding handles both thin and thick materials without frequent equipment changes, saving costs on multiple machines.

Better Ways to Repair and Improve Parts

I find that laser welding machines are a great way to fix and improve industrial parts. They make the repair process much more efficient and improve its quality.

On-Site Repairs, Even in Tricky Spots

I appreciate that mobile diode laser systems can repair parts on-site—no need to disassemble heavy equipment. I’ve seen cracks fixed 25 meters up without removing machinery, reducing downtime and cutting shipping and handling costs.

Good for Small and Delicate Parts

I believe laser welding is perfect for making things smaller in high-tech production because it’s so precise. It allows for: – Repairs on very small parts like circuit boards, sensors, and electronic chips. – Fixing detailed molds for plastic injection and metal die casting.

From my point of view, this means we can fix delicate, costly parts fast, getting them back to how they should be, instead of just throwing them away. This saves a lot of money on replacement parts for items like micro-sensors.

Competitive Market Advantage

Laser welding machines give manufacturers a strong competitive edge. The global market, valued at USD 1.96 billion in 2021, is projected to reach USD 2.79 billion by 2029 with a 4.7% CAGR. This technology is becoming essential for companies aiming to stand out.

Production Reshoring and Automation

- Across different industries, I see businesses building new facilities in developed economies. Many of these plants are choosing advanced automation tools like laser welding. This choice helps them keep production costs competitive with rivals overseas.

- From my experience, laser welding improves manufacturing visibility and process transparency. It also boosts overall efficiency because it integrates easily with digital control systems.

- I believe companies gain a stronger market position when customers value products made in their own region and to high standards.

Summary

I’ve seen these benefits myself. I truly believe laser welding is the future of making things. It offers precision, efficiency, and helps the environment. In my opinion, this is more than just new technology. It completely changes how we make products. I think if manufacturers want to compete and build a sustainable future, they should consider laser welding. I suggest it’s not just a good business move. I believe it’s vital for long-term success. For more details about handheld laser welder or to get a quote, contact us today!