Laser welding technology has revolutionized modern manufacturing, automotive, precision repair, and jewelry processing. Its advantages of high efficiency, exceptional precision, and minimal thermal distortion make it indispensable for achieving superior product quality. Choosing the right laser welding machine is crucial for boosting productivity and gaining a competitive edge. This guide compiles a list of the world’s best-selling laser welders, covering a range of powers, configurations, and price points to help you find the perfect commercial solution for your needs.

| Product Name | Approximate Price |

| MAXWAVE MW-AR200 | $5,000 – $9,000 |

| OMTech Handheld Fiber Laser Welder | $9,000 – $16,000 |

| Trumpf TruLaser Cell Series 1000 | Starts from $150,000 (can exceed $400,000) |

| Coherent ExactWeld 230 | $45,000 – $75,000 |

| Xlaserlab X1 Pro | $15,000 – $25,000 |

| SFX Industrial 1200W Air-Cooled | $4,000 – $7,000 |

| LaserPhotonics WeldTech CW-6010 | $18,000 – $28,000 |

| xTool MetalFab | $6,000 – $10,000 (Estimated) |

| Wattsan 5-in-1 G2 PRO | $12,000 – $25,000 |

| Hans Laser FP300 | $20,000 – $35,000 (Estimated) |

1.MAXWAVE MW-AR200: The Automated Desktop Welder for Consistent Output

For small businesses needing automated, repeatable welding for small components, the MAXWAVE MW-AR200 offers a CNC-controlled solution with a compact work area, ensuring consistent quality batch after batch.

Specifications:

-

Laser Power: 200W

-

Control: Industrial PC with CNC2000 software

-

XY Axis Travel: 200 x 300 mm

-

Welding Thickness: 0 – 1.2mm

-

Lamp: Single Ceramic Chamber Xenon Lamp

-

Price: A cost-effective automated solution, estimated at $5,000 – $9,000.

Advantages:

-

Fully Automated: The CNC system ensures every weld is identical, perfect for small, repetitive production runs.

-

Compact and Self-Contained: Its desktop footprint fits easily into smaller workshops or labs.

-

Consistent Quality: Removes the variability associated with manual welding.

-

Cost-Effective Automation: Provides the benefits of CNC automation at a lower entry price than large industrial systems.

Disadvantages:

-

The 200W power and 1.2mm thickness limit make it suitable only for very fine, light-gauge welding.

-

The work area is small, restricting the size of parts that can be processed.

2.OMTech Handheld Fiber Laser Welder: The Versatile Powerhouse for Workshops

If your small or medium-sized workshop needs a flexible, easy-to-use machine capable of handling a variety of metals, the OMTech max 1500W laser welding machine is an excellent choice. It brings industrial-grade power to your fingertips.

Specifications:

-

Laser Type: Fiber Laser

-

Laser Power: 1500W

-

Work Mode: Handheld welding with integrated wire feeder

-

Compatible Materials: Stainless steel, carbon steel, aluminum (up to 2mm), zinc plate (up to 4mm)

-

Price: Approximately $9,000 – $16,000, depending on configuration and regional tariffs.

Advantages:

-

All-in-One Solution: Integrates the welder, torch, and wire feeder, simplifying setup and operation.

-

Intelligent Torch: Features 20 nozzles and sensitive throttle control for quick, clean, and efficient welding.

-

User-Friendly Control: Intuitive touchscreens on both the machine and torch allow for real-time monitoring and quick adjustments.

-

Comprehensive Protection: Built-in alarms for low voltage, extreme temperatures, and short circuits, along with an emergency stop button for safe operation.

Disadvantages:

-

The welding thickness for harder materials like aluminum is limited compared to its performance on steel.

-

As a powerful handheld unit, it requires operators to wear appropriate protective gear and ensure adequate ventilation.

3. Trumpf TruLaser Cell Series 1000: The Automated Robotic Laser Welding Cell

For manufacturers pursuing ultimate efficiency and consistency in large-scale production, the Trumpf TruLaser Cell 1000, integrated with industrial robotics, is the undisputed choice. It represents the pinnacle of automation in laser welding.

Specifications:

-

Laser Type: CO₂ Laser or Solid-State Laser

-

Laser Power: Configurable, typically from 2000W to 6000W+

-

System Composition: High-power laser source + 6-axis industrial robot + dedicated worktable

-

Control System: Integrated CNC with offline programming

-

Weldable Materials: Steel, stainless steel, aluminum, non-ferrous metals (thickness from 0.1mm to several mm)

-

Price: A significant investment, typically starting from $150,000 and can exceed $400,000.

Advantages:

-

Extreme Flexibility: Capable of continuous welding of arbitrary seam geometries on strips, tubes, and profiles.

-

Unmatched Precision: Advanced seam detection and tracking sensors (e.g., SeamLine Pro) ensure consistent, high-quality welds.

-

High Profitability: State-of-the-art beam sources and automation reduce operational costs and increase throughput.

-

Intuitive Operation: Integrated control panel simplifies the operation of this complex system.

Disadvantages:

-

The initial investment is very high, and it requires considerable floor space.

-

Requires specialized personnel for programming, maintenance, and operation.

4. Coherent ExactWeld 230: The Desktop Precision Point Welder

For applications in jewelry, medical devices, and electronics that require micron-level precision for micro-small components, the Coherent ExactWeld 230 laser welder offers unparalleled accuracy and reliability in a compact package.

Specifications:

-

Laser Type: Fiber Laser

-

Laser Power: 400W

-

Weld Spot Size: Capable of very fine spots suitable for micro-welding.

-

Positioning System: High-precision XY stage with 0.06mm accuracy.

-

Work Area: 400 x 400 mm

-

Price: Approximately $45,000 – $75,000.

Advantages:

-

Patented SmartWeld™ Technology: Bridges larger gaps and relaxes assembly tolerances, simplifying fixture design.

-

Exceptional Precision: The high-accuracy stage and focused laser beam are ideal for delicate components.

-

Fast Changeover: Quick-release joints allow for swift switching between welding and cutting applications.

-

Compact Footprint: Its desktop design saves valuable production floor space.

Disadvantages:

-

The work area is limited, making it unsuitable for very large parts or long seams.

-

The 400W power is designed for precision work, not for deep penetration welding on thick materials.

5. Xlaserlab X1 Pro: The 3-in-1 Welding, Cleaning, and Cutting Combo

This is an innovatively functional device, particularly suited for the repair and remanufacturing sector where dealing with rust, oil, or paint removal before welding is common. The Xlaserlab X1 Pro combines three critical processes in one compact machine.

Specifications:

-

Laser Functions: Welding + Cleaning + Cutting

-

Laser Power: 1000W (estimated, modes may be switchable)

-

Design: Compact, portable desktop unit (21 kg)

-

Control: 7-inch touchscreen with one-touch presets

-

Price: Estimated at $15,000 – $25,000.

Advantages:

-

Three Machines in One: Saves on equipment cost and space by combining welding, cutting, and cleaning.

-

Enhances Weld Quality: The cleaning function ensures weld surfaces are contaminant-free, leading to stronger bonds.

-

Eco-Friendly Cleaning: No chemicals or consumables are needed for the cleaning process.

-

Portable and Smart: Its light weight and intuitive touchscreen make it easy to use anywhere.

Disadvantages:

-

Performance in each individual function may not match that of a dedicated, single-purpose machine.

-

Switching between modes may require pauses, potentially impacting continuous workflow efficiency.

6. SFX Industrial 1200W Air-Cooled: The User-Friendly 2-in-1 Welder

For small businesses and workshops looking for an easy entry into laser welding, the SFX 1200W offers a compelling combination of core welding functionality and user-friendly features at an accessible price point.

Specifications:

-

Laser Power: 1200W

-

Cooling System: Air-cooled

-

Function: Welding + Beam Cleaning

-

Torch Weight: 0.65 kg (extremely lightweight)

-

Control: 7-inch intuitive touchscreen

-

Price: Highly affordable, typically between $4,000 – $7,000.

Advantages:

-

Beginner-Friendly: Features a “Novice Mode” with 40 presets, allowing users to select material type and thickness for easy operation.

-

2-in-1 Functionality: Seamlessly switch between welding and cleaning modes to smooth the workpiece surface post-weld.

-

Lightweight Torch: At only 0.65kg, it reduces operator fatigue during prolonged use.

-

Fast and Versatile: Welds 4-10x faster than traditional methods and works on stainless steel, aluminum, brass, and copper.

Disadvantages:

-

Single-side melting depth is limited to 3mm, restricting its use on thicker materials.

-

Being air-cooled, it may have limitations on sustained duty cycles in very demanding, continuous operations.

7. LaserPhotonics WeldTech CW-6010: The Compact and Smart Portable Laser Welding System

Ideal for on-site or in-warehouse applications, the WeldTech CW-6010 is a compact, portable system designed to enhance welding consistency and quality for operators of all skill levels through its intelligent automation.

Specifications:

-

Laser Power: 1500W

-

Laser Safety Class: Class IV

-

Operation Mode: Continuous Wave (CW)

-

Cable Length: 5.6 meters (aids in portability)

-

Cooling System: Air-cooled

-

Weight: System total 40 kg

-

Price: Estimated at $18,000 – $28,000.

Advantages:

-

Automated Power Adjustment: Operators select from 24 material patterns and set thickness; the system auto-adjusts power output.

-

Portable and Self-Contained: Easy to move for on-site jobs without the need for external chiller units.

-

Safe and Eco-Friendly: No flammable gases or electrodes required. The laser ablates surface contaminants, eliminating pre-weld treatment.

-

Versatile Material Compatibility: Works with a wide range of metals, including structural steel, copper, titanium, aluminum, and refractory metals.

Disadvantages:

-

As a Class IV laser system, it requires strict adherence to safety protocols, which may involve additional safety infrastructure.

-

While portable, the total system weight of 40kg is less mobile than ultra-lightweight handheld-only units.

8. xTool MetalFab: The All-in-One Smart Laser Welding and Cutting Solution

Positioned as the world’s first smart laser welding solution and CNC cutting solution for metal, the xTool MetalFab is designed for creators, small businesses, and educational institutions looking for an integrated and intelligent entry into metal fabrication.

Specifications:

-

Laser Power: 1200W (Stable Output)

-

Capabilities: Laser Welding + CNC Cutting

-

Cutting Precision: 1mm

-

Welding Thickness: 0.008 inches to 0.2 inches

-

Features: Smart dual-camera system, proprietary software

-

Price: Estimated between $6,000 – $10,000.

Advantages:

-

Integrated Workflow: Combines two key processes (welding and cutting) in a single, software-driven platform.

-

Smart Assistance: Dual cameras and intelligent software simplify alignment and operation, reducing the learning curve.

-

High Material Utilization: Up to 98.7% material usage rate, minimizing waste.

-

10x Efficiency: Claims a significant increase in efficiency compared to traditional methods.

Disadvantages:

-

The primary market is hobbyists, creators, and small-scale prototyping; it may not be robust enough for heavy industrial environments.

-

The welding and cutting thicknesses are suitable for light-gauge metals but not for heavy plates.

9. Wattsan 5-in-1 G2 PRO: The High-Power Multi-Function Handheld System

For users who need maximum versatility and power from a handheld system, the Wattsan 5-in-1 G2 PRO is a robust laser welding machine capable of cutting, deep-penetration welding, cleaning, and even storage welding.

Specifications:

-

Laser Source: JPT/Raycus Fiber Laser

-

Laser Power Options: 1500W, 2000W, 3000W

-

Functions: Welding, Cutting, Cleaning, Seam Cleaning, Storage Welding

-

Weld Depth: Up to 7mm

-

Seam Types: Offers various patterns (e.g., line, circle, infinity, triangle)

-

Price: Varies with power, typically $12,000 – $25,000.

Advantages:

-

Exceptional Versatility: Five core functions in one machine, adaptable to numerous tasks.

-

High Power Options: Up to 3000W power allows for deep penetration (up to 7mm) on thick materials.

-

Programmable Weld Patterns: The software allows users to create complex weld seams beyond simple lines.

-

Optional Dual Wire Feeder: Can fill larger gaps up to 8mm.

Disadvantages:

-

The high power and multitude of functions come with a steeper learning curve to master all capabilities.

-

The welding head, while lightweight for its power, is heavier (0.8kg) than some entry-level models.

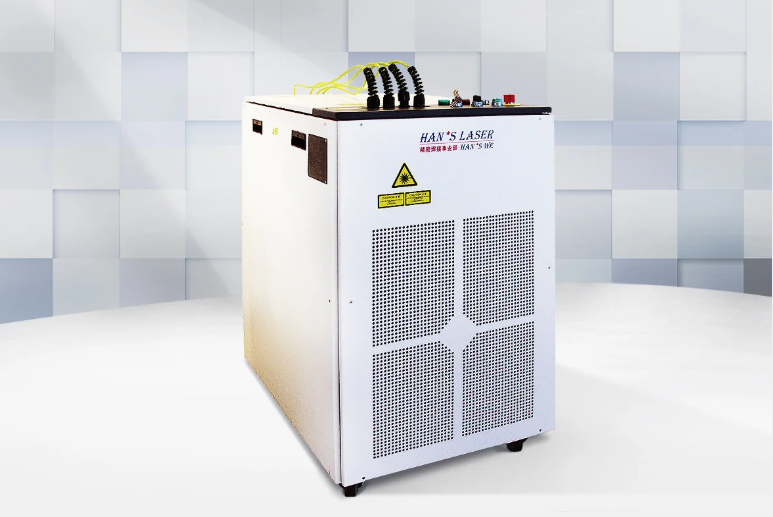

10. Hans Laser FP300: The Precision Laser Welding Workhorse for Specific Industries

The Hans FP300 laser welder is engineered for high-speed, high-aspect-ratio welding with a minimal heat-affected zone. It excels in industries like battery manufacturing, precision instrumentation, and medical devices where zero distortion is critical.

Specifications:

-

Key Features: High aspect ratio, narrow weld width, small heat-affected zone, high speed.

-

Applications: Battery welding, pipe welding, thin sheet metal, electronic components, medical devices.

-

Compatible Materials: Stainless steel, carbon steel, gold/silver alloys, aluminum, copper, titanium.

-

Weld Types: Excellent for spot welding, butt welding, and seam sealing.

-

Price: Industry-specific pricing, estimated from $20,000 – $35,000.

Advantages:

-

Zero Distortion: The narrow HAZ and fast welding speed prevent part warping, crucial for precision assemblies.

-

High Strength Welds: Produces pore-free welds with a refined microstructure, achieving strength equal to or greater than the base metal.

-

Perfect for Automation: The small laser spot allows for precise positioning, making it ideal for integration into automated production lines.

-

Versatile for Metals: Suitable for welding dissimilar metals, expanding its application potential.

Disadvantages:

-

This is a specialized machine optimized for specific, high-precision industries; it may be over-engineered for general-purpose workshop use.

-

Technical specifications suggest a focus on thin materials, not heavy structural welding.

Summary

Laser welding technology delivers immense value to users across all scales and industries by enhancing quality, boosting efficiency, and enabling advanced automation. The best-selling machines highlighted here have been proven and trusted in the global market, representing reliable choices for a wide array of applications. We encourage you to assess your specific needs, budget, and operational context to select the ideal equipment from these top-tier recommendations. Ready to transform your fabrication capabilities? Contact us today for a personalized quote and solution!