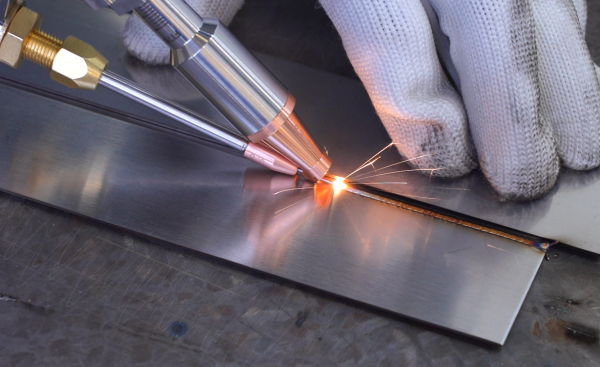

Looking to level up your welding game? Whether you’re running a fabrication shop, launching a new business, or upgrading your factory line, choosing the right 1000W best laser welding machine can transform your workflow. These compact powerhouses are 2–10 times faster than traditional TIG welding, require less post-processing, and combine welding, cleaning, and even cutting into one efficient system.

In this guide, we break down the top performers in the 1000W category—machines trusted by industry pros for their speed, precision, and versatility. If you’re ready to boost productivity and cut operational costs, read on. Your next great investment might just be a laser away.

MaxWave 3 in 1 Handheld Laser Welding Machine

I’ve found the MaxWave 3-in-1 Handheld Laser Welding Machine to be an outstanding performer in the 1000W category. It’s especially well-suited for entrepreneurs and businesses seeking a high cost-performance ratio, space efficiency, and multifunctional integration. In addition to standard welding tasks, it also supports metal cleaning and thin-sheet cutting, enabling users to tackle various processes with a single compact unit.

Key Technical Specifications

Laser Type: QCW laser

Welding Depth: Up to 5mm (depending on material)

Integrated Functions: Welding + Cutting + Cleaning (3-in-1)

Welding Modes: Continuous, spot, and swing welding

Cooling System: Air-cooled system — no external chiller needed, compact design, flexible deploymen

Performance Efficiency

Offers welding speeds 2–10 times faster than traditional TIG welding. It supports continuous operation with minimal post-weld treatment required, significantly reducing labor and time costs. Ideal for small to mid-sized factories, workshops, and mobile applications.

Ease of Operation

Equipped with a lightweight handheld welding gun and an intuitive smart touchscreen interface, the best laser welding machine makes parameter adjustments straightforward. Beginners can operate the machine in just 30 minutes — ideal for fast onboarding and multi-process flexibility.

System Advantages

This highly integrated system truly delivers “all-in-one” functionality. Its air-cooled design reduces maintenance costs, and the compact structure saves valuable workspace. Built-in safety mechanisms ensure safe operation while enhancing spatial efficiency.

Han’s Laser HW-D Laser Welding Machine

The Han’s Laser HW-D laser welding machine is a standout in the 1000W category. It’s designed with an emphasis on welding depth, process stability, and compatibility with large-scale industrial manufacturing. It’s a dependable solution for demanding applications like sheet metal fabrication, repairs, and production lines.

Key Technical Specifications

Laser Type: Continuous fiber laser

Welding Depth: Up to 3mm (depending on material)

Function Configuration: Welding + Cleaning (cutting supported in some models)

Welding Modes: Continuous, spot, and swing welding

Cooling System: Built-in water cooling — ideal for high-load, long-duration operation with precise temperature control

Performance Efficiency

Delivers welding speeds 2–10 times faster than TIG welding. Provides stable, reliable performance during extended use. Minimal post-processing is needed, making it well-suited for batch production environments.

User Experience

The ergonomic handheld welding gun provides excellent maneuverability. Its industrial-grade touchscreen control system enables quick and intuitive parameter adjustments. Easy to operate and ideal for rapid deployment in production lines.

Equipment Advantages

Highly integrated and optimized for fixed production line setups. The water-cooling system enhances long-term operational stability and equipment lifespan. Comprehensive safety protection mechanisms ensure reliable performance under high workloads.

DPLaser Handheld Laser Welding Machine

From my experience, the DPLaser handheld laser welding machine is built for robust industrial use. It emphasizes powerful performance, modular functionality, and integration flexibility, making it suitable for complex, high-demand manufacturing environments that require both precision and output strength.

Key Technical Highlights

Laser Type: Continuous fiber laser

Welding Depth: Up to 4mm, suitable for slightly thicker materials

Functions: Primarily welding, with optional cleaning and cutting

Welding Modes: Continuous, spot, swing welding

Cooling System: Integrated water cooling, ensuring stable output during heavy-duty, long-duration operation

Efficiency Focus

DPLaser laser welding machine excels in sustained industrial productivity, with speeds up to 10x faster than TIG/MIG. The system is designed to minimize spatter and distortion, allowing for cleaner welds and reduced post-processing time — especially critical for batch production lines or high-output tasks.

Operation Experience

Designed for long working hours, the welder features an ergonomic gun with smart balancing. Its intelligent control interface offers fast, precise adjustments. Though powerful, it maintains user-friendliness for operators with minimal training.

Distinctive Advantages

The DPLaser model laser welding machine is aimed at factories or workshops needing multi-mode processing and consistent high power. Its modular design and multi-process support (welding + optional cleaning/cutting) offer flexibility for diverse industrial workflows. The sturdy build and internal cooling prioritize durability and uptime.

Senfeng HWM Series Laser Welding Machine

If you’re targeting fast, precise metal processing in custom fabrication or agile manufacturing, the Senfeng HWM Series laser welding machine offers a more streamlined, operator-friendly solution. It’s designed with simplicity, compactness, and usability in mind, making it ideal for on-site jobs, repair stations, and mid-volume production.

Key Technical Highlights

Laser Type: Continuous fiber laser

Welding Depth: Up to 4mm, ideal for sheet metal and small components

Functions: Welding and cleaning (cutting optional)

Welding Modes: Continuous, spot, swing welding

Cooling System: Built-in water chiller, for reliable thermal control in medium-duty tasks

Efficiency Focus

As one of the best laser welding machine options on the market, it offers welding speeds 2–10x faster than traditional techniques. Its design favors low-maintenance operation, fast setup, and reduced downtime — perfect for businesses that need mobility or quick turnaround.

Operation Experience

Prioritizes ease of use with a lightweight gun and intuitive control interface. Even in tight or complex positions, operators can weld with precision. The learning curve is short — typically within 30 minutes — making it great for job shops or fast-paced repair environments.

Distinctive Advantages

Senfeng HWM laser welding machine stands out with its compact design, integrated control, and safety-first approach (e.g., interlock protection, over-temp alarms). Compared to DPLaser, it’s less focused on heavy industrial output, and more geared toward flexibility, fast deployment, and space-saving setups.

Buying Considerations for Industrial Users of Laser Welding Machine

Okay, let’s talk about what I think you should consider when buying a 1000W industrial laser welding machine. From my experience, focusing on a few key things will help you get the best results.

Match Machine Specs to Your Job

Know Your Welding Needs: I suggest you define your common materials. Think about part thickness; I find 0.5–3mm is a good range. Also, consider your needed welding speed, which can go up to 120 mm/s. In my experience, fiber laser welders are very good for non-stop, heavy work with metals like steel, aluminum, copper, and alloys.

Laser Types: I believe fiber lasers give great beam quality and save energy for most metals. If you work with very thick materials, CO₂ lasers might be a better choice. Solid-state lasers are flexible if you need to do both cutting and welding.

Key Technical Specs I Recommend You Check

Laser Power: For industrial welding in that 0.5-3mm thickness range, I find 1000W is often just right. If your jobs are thicker, you’ll need more power.

Beam Quality: I suggest you look at this closely. It really makes a difference in how precise your weld is and how good it looks.

Pulse Duration & Spot Size: In my experience, these settings help you control the heat. They also affect how the seam looks and help reduce any warping.

Check Material & Workshop Fit

Works with Your Metals: I strongly advise making sure the laser welder can handle all the materials you use. Common ones are stainless steel, carbon steel, aluminum, copper, and brass. You might also need it for special alloys or even plastics.

Electrical Match: I’ve seen most industrial models run on 220V. I recommend you always check this against what your shop has.

Operating Temperatures: In my experience, these machines operate best between 15–35°C. I suggest you make sure your workshop conditions are suitable.

More Things I Suggest You Consider

Training After You Buy: In my opinion, good training and help with setup can cut down on operator mistakes. It also speeds up how quickly you get to full production.

Spare Parts and Service Access: I advise making sure the brand can support you in the long run. This means having parts and service readily available.

Proof of Performance: I recommend you ask for detailed performance data. Also ask for certifications and what other industrial users in your field say about them.

For example, the MaxWave 3-in-1 Handheld Laser Welding Machine is not only easy to operate and quick to learn—with training that helps beginners get started fast—but also backed by 24/7 after-sales support and global spare parts delivery for worry-free use. The machine is CE, ISO, and FDA certified, widely used across multiple industries, and trusted for its stable and reliable performance.

Summary

I’ve checked out these advanced best laser welding machines, and I’m quite sure they are the future for metal work. In my view, they combine power, precision, and versatility well. From my experience, this mix really changes what’s possible in any workshop, big or small. You could pick the MaxWave for its all-around flexibility or Han’s Laser for reliable production. Maybe DPLaser for industrial power, or Senfeng because it’s easy for operators to use. Whichever you choose, I believe you’re investing in technology that will greatly improve your output and what you can make. Manufacturing keeps changing. I think these tools are vital to compete in today’s demanding market. For more details about 3 in 1 handheld laser welding machine or to get a quote, contact us today!