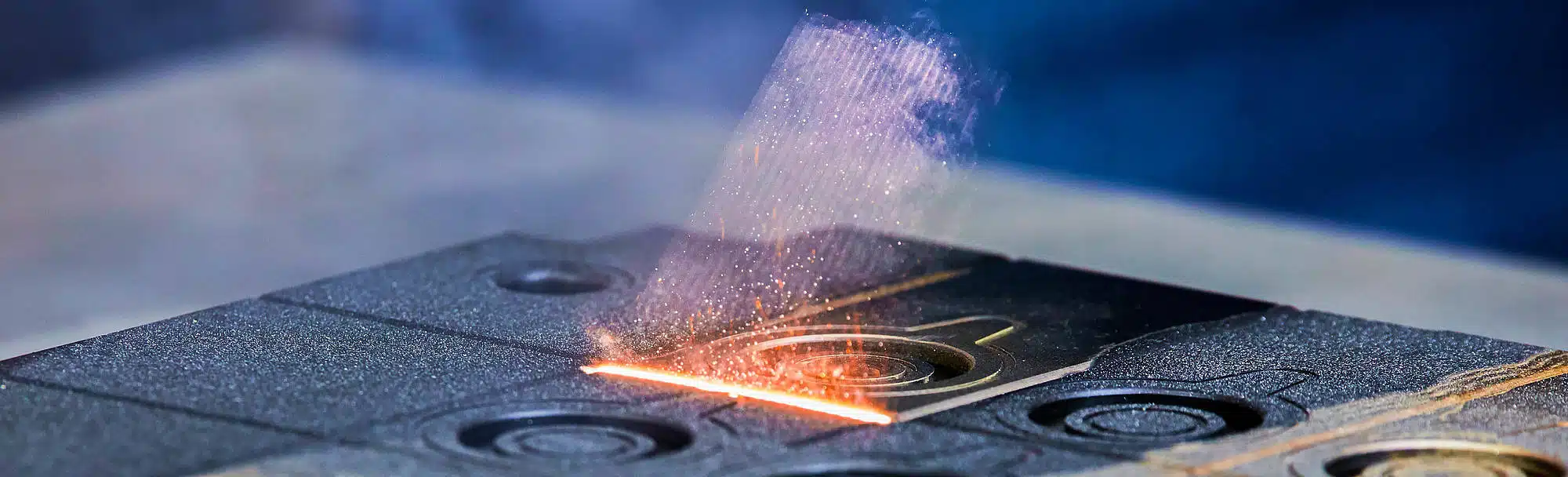

In a world where precision, speed, and sustainability matter more than ever, laser cleaning machines have become a game-changer for industries ranging from aerospace to automotive. Whether it’s removing rust, paint, or contaminants, these high-tech tools deliver unmatched efficiency and accuracy. Today, we’re diving into the top 10 manufacturers worldwide that are setting the benchmark for innovation, reliability, and performance in laser cleaning technology.

Price Range of Laser Cleaner

| Brand | PEstimate Price) |

| MaxWave | US $5,500–$17,500 |

| CleanLASER | US $40,000–$60,000 |

| Trumpf | US $8,800–$10,000 |

| LaserAX | US $60,000–$85,000 |

| P‑Laser | US $5,000–$30,000 |

| SFX | US $5,900–$10,000 |

MaxWave Laser: Affordable and Green Laser Cleaning Systems

MaxWave Laser is based in Wuhan, China. I recommend them for their precise and green laser cleaning systems. They deliver efficient tools at fair prices.

Key Laser Cleaning Products and Models

- MW-LY series: A portable air-cooled laser cleaner built for flexible, on-site jobs.

- MW-LCW series: A water-cooled, fixed industrial model built for continuous, stable, long-duration factory operation.

- MW-LC series: A battery-powered backpack laser cleaner, perfect for mobile on-site jobs.

Every models handle various cleaning tasks in different places.

Core Technology Benefits

MaxWave uses advanced fiber laser sources for precise cleaning with minimal surface damage and offers both pulsed and continuous laser options to suit different cleaning needs. The systems feature energy-efficient designs that reduce power consumption and lower operating costs. The backpack version with an optional battery provides maximum mobility, while the cleaning head supports 8 modes and uses high-purity quartz lenses for improved durability and performance.

Main Application Industries

I’ve seen MaxWave Laser products used in:

- Manufacturing for preparing and maintaining machine parts.

- Automotive shops for removing rust and prepping surfaces.

- Shipbuilding yards to clean hulls and strip coatings.

- Construction sites for cleaning and restoring building parts.

Market Presence

MaxWave Laser distributes across Asia and Europe. I suggest their laser cleaning systems for cost-conscious customers who need high output. You get effective laser cleaning. You don’t pay a large upfront cost.

Special Features and Innovations

MaxWave offers portable, plug-and-play laser cleaning machines that require virtually no maintenance. These plug-and-play systems perform reliably across various environments, making them ideal for both small businesses and large industrial users. With affordable pricing and low total ownership costs, MaxWave machines deliver efficient, sustainable, and hassle-free operation.

CleanLASER: Precision Laser Cleaning Systems from Germany

CleanLASER is based in Herzogenrath, Germany. I see them as a leader in laser cleaning machine. They build their own fiber laser design. They also hold patents on their control electronics. This gives you exact adjustment while cleaning. CleanLASER uses special optics too. Their equipment works well on delicate surfaces and tough jobs alike.

Key Laser Cleaning Products

- CL 100

- CL 500

- CL 1200

- CL 1500

- CL 3000

These models handle all your laser cleaning needs. They go from gentle surface prep to heavy industrial work.

Core Technology Advantages

MaxWave’s customized fiber laser design delivers stable and efficient performance, supported by advanced control electronics that ensure precise and repeatable cleaning results. You can also adjust the pulse settings to keep the substrate safe during the cleaning process. In addition, the system uses special optical components that adapt to different materials and contaminants, providing a more flexible and reliable cleaning experience.

Major Application Industries

I recommend CleanLASER’s systems for:

– Automotive manufacturing (they supply major German automotive OEMs)

– Aerospace engineering

– Tool and mold cleaning

– Art restoration and historical conservation

Market Scope and Global Reach

Available in more than 50 countries Users praise their high reliability and easy integration into automated production lines

Special Features & Innovations

CLM mobile system lets you clean on-site. This gives you more flexibility. Adjustable pulse technology protects delicate surfaces. It also makes your equipment last longer.

Trumpf: Advanced Laser Cleaning machines from Germany

Trumpf is based in Ditzingen, Germany. I recommend them as a top choice for industrial laser cleaning systems. They excel in laser cleaning and surface prep.

Key Laser Cleaning Products and Models

- TruMicro series

- TruLaser

- Automated laser cleaning solutions

These models handle many industrial cleaning tasks. They work for precision component prep. They also handle large-scale automated cleaning.

Core Tech Advantages

Trumpf focuses on short-pulse and ultrashort-pulse laser technology, delivering high cleaning efficiency while protecting the base materials. Their laser systems can also be seamlessly integrated into automated production lines, making them highly suitable for smart manufacturing.

Main Application Industries

I’ve seen Trumpf’s laser cleaning systems used in:

– Auto manufacturing (paint and coating removal, pre-weld cleaning)

– Aerospace (precision surface prep, part refurbishment)

– Electronics manufacturing (delicate substrate and component cleaning)

Market Presence and Reputation

Trumpf has a strong position in Europe. Customers around the globe trust them. Top automotive and aerospace companies choose Trumpf. They value the proven reliability and performance.

Special Features and Innovations

Their systems use a modular automation interface that adapts easily to different production setups, while digital process monitoring supports modern smart factory needs by tracking cleaning quality and improving overall efficiency.

LaserAX: Laser Cleaning Systems for Battery and Auto Industries

LaserAX is based in Montreal, Canada. They focus on industrial laser cleaning. I recommend them for automation and safety on sensitive production lines.

Key Laser Cleaning Products and Custom Solutions

- AX1500

- AX1000

- Custom laser cleaning solutions that fit your production setup

These systems handle tough cleaning jobs. You can choose ready-made models or custom designs.

Core Technology Advantages

The UltraShield™ Safety Technology protects lithium-ion battery production lines by reducing fire risks, while its precision control removes paint, oxides, and coatings safely, ensuring that your base materials remain intact.

Main Application Industries

I see LaserAX’s technology used in:

- Battery Manufacturing: EV battery cell production lines use it. This includes dry rooms and welding prep areas.

- Automotive: Pre-welding surface prep is a popular use. It gives you consistent cleaning. Joint strength improves.

- Heavy Industry: It handles strong cleaning needs in factories.

Market Presence and Industry Impact

Global leaders trust LaserAX solutions. Over 60% of Tesla and Panasonic EV battery lines use LaserAX equipment. The company leads in North America. Asia sees fast growth. The Asian market grew 300% per year.

Special Features and Innovations

P-Laser: Portable Industrial Laser Cleaning Machines from Belgium

P-Laser has its headquarters in Genk, Belgium. The company makes portable laser cleaner, industrial-grade fiber laser cleaning machines. I find their systems truly plug-and-play. You can use them in the field or factory with ease.

Key Laser Cleaning Products and Models

- QF-Compact

- QF-1000+

- QF-2000

These models work well for many cleaning jobs. They handle local repairs. They also tackle large-scale projects.

Core Technological Advantages

All P-Laser machines use fiber laser sources that deliver stable performance and a long service life. They are built to operate in tough environments, allowing you to use them directly in the field. In addition, their custom interface supports robotics and factory automation systems, making integration smooth and efficient.

Main Application Industries

I recommend P-Laser’s technology for these uses:

- Shipbuilding: It removes rust and strips paint. It preps surfaces on ships and offshore structures.

- Heavy Equipment Maintenance: It cleans industrial machines, tools, and parts. It removes oil, rust, and industrial paints.

- Conservation and Restoration: Based on my experience, it works well for sensitive tasks. You can clean historical buildings and artifacts.

Global Market Presence

P-Laser sells its machines in more than 35 countries. I like their field-ready solutions. They work reliably in harsh environments. They adapt to different conditions.

Special Features and Innovations

Plug-and-play startup means you can start cleaning fast. You don’t need complex setup. You can program cleaning patterns yourself. This gives you more control. You can optimize cleaning for different materials. You can adjust for different contaminant types. I suggest using this laser machine of cleaning to improve your results.

SFX: High-Power Laser Cleaning Machines from China

Located in Orlando, Florida, Laser Photonics is renowned for its CleanTech laser cleaning series—robust, efficient, and eco‑friendly. Their laser cleaner machines are trusted globally in demanding industrial, aerospace, and research settings.

Key Laser Cleaning Products and Models

-

LPC‑500‑CTHD: A compact, air-cooled, pulsed handheld cleaner that offers high precision and safety.

-

LPC‑1000‑CTH: 1000 W industrial-grade system, capable of robot integration and advanced automation.

-

3000‑CTH (3 kW): A high-power unit for tackling heavy rust, thick coatings, and large-area surfaces, with built-in cooling for continuous operation.

Core Technological Advantages

Laser Photonics’ CleanTech systems provide high-efficiency, eco-friendly cleaning without chemicals or abrasives, ensure safe operation with minimal thermal impact on sensitive materials, offer real-time control with multiple cleaning modes, and are modular and customizable to fit diverse production and automation requirements.

Main Application Industries

-

Aerospace: For cleaning engine components, airframe structures, and removing coatings.

-

Automotive: Pre‑weld surface preparation, contaminant removal, and coating stripping.

-

Maritime & Shipbuilding: Large-scale maintenance and decontamination of ship hulls.

-

Energy & Power: Maintenance of industrial equipment, corrosion control, and surface regeneration.

Market Presence

Laser Photonics’ CleanTech systems serve clients worldwide, from high-tech research labs to heavy industrial sites. They maintain a strong service network to provide technical support, spare parts, and system upgrades.

Special Features and Innovations

The LPC‑500‑CTHD is ergonomically designed for comfort and precise control, while the high-power 3 kW 3000‑CTH handles heavy-duty cleaning with integrated cooling. Both CleanTech systems run consumable-free, reducing operating costs and improving environmental sustainability.

Summary

Choosing the right laser cleaning machine can transform your operations, saving time, money, and reducing environmental impact. From portable handheld units to powerful industrial systems, the brands on our list offer cutting-edge performance, long-term reliability, and versatile solutions for any application. Ready to elevate your cleaning process and explore the ideal machine for your needs? Contact us today to request a personalized quote and see which laser system fits your business perfectly.