The modern manufacturing landscape relentlessly pursues two goals: unparalleled quality and blistering efficiency. Nowhere is this more evident than in the realm of joining technologies, where the demands for stronger, faster, and more precise welds are constantly escalating. While traditional laser welding, known as autogenous welding, offers remarkable speed and a small heat-affected zone, it hits its limits when faced with real-world challenges. Its primary weakness? A near-zero tolerance for part fit-up gaps and limited ability to alter the weld metal’s chemistry. This is where innovation sparks a new era. By integrating a high-precision laser welder with an automatic welding wire supply system, we achieve a powerful synergy where the whole is far greater than the sum of its parts. This article will delve into the five core benefits that this formidable combination brings to industries far and wide.

Elevating Weld Integrity and Uniformity

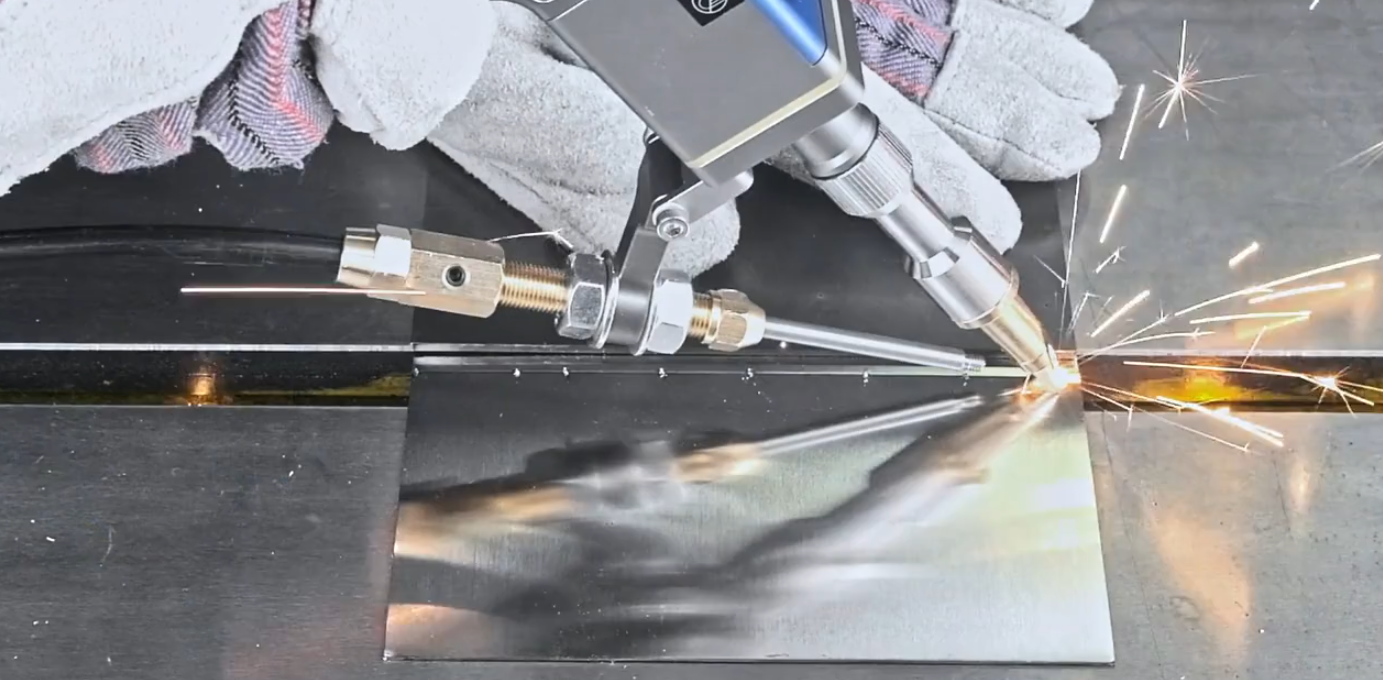

Bridging Weld Gaps with Precision

Autogenous laser welding fails dramatically when there’s even a microscopic gap between components, leading to severe undercut, sinkholes, or collapse. The integration of an automatic wire feeder is the definitive solution. It strategically introduces filler metal into the laser-generated weld pool, effectively filling any voids or inconsistencies in the joint preparation. This capability is a game-changer for achieving first-pass success, drastically reducing scrap rates, and minimizing the need for costly and time-consuming rework. It transforms a critical process limitation into a controllable variable, ensuring robust welds even in less-than-ideal assembly conditions.

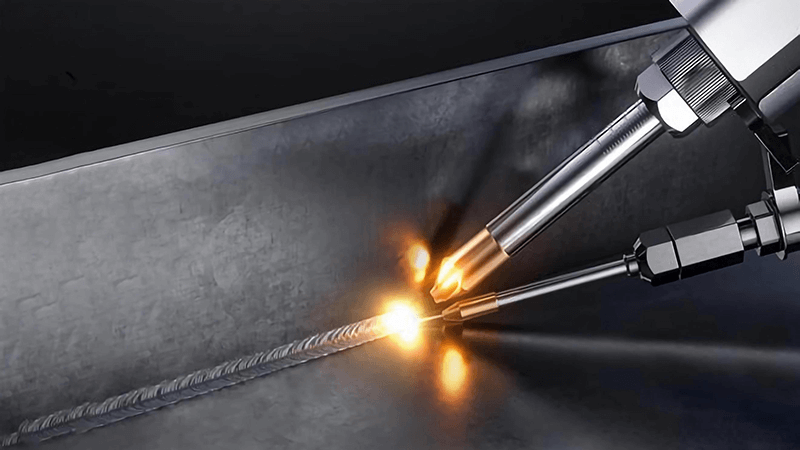

Mastering the Art of Weld Bead Profiling

The beauty of laser welding with wire feed lies in the unprecedented command it grants over the final weld’s geometry. By precisely calibrating the wire feed speed, angle, and placement relative to the laser beam, operators can sculpt the weld bead to exact specifications. Whether the requirement is for a specific reinforcement (weld crown), a particular width, or a smooth transition to the base material, this system delivers. This level of control is paramount not only for aesthetic applications, like consumer products, but also for components where the weld profile directly impacts fatigue life and mechanical strength.

Enhancing Weld Metallurgy for Superior Performance

This system unlocks the potential to engineer the weld’s metallurgical properties. Instead of being confined to the composition of the base materials, you can select a welding wire with specific alloying elements to enhance the weld’s characteristics. For instance, a wire rich in manganese and silicon can improve strength and deoxidize the weld pool. Furthermore, this is the key to welding dissimilar materials that were previously considered incompatible. Imagine creating a high-strength, crack-free joint between copper and steel, or aluminum and steel—a task that is notoriously difficult with other methods. This dramatically expands the horizons for lightweight and multi-material structure design.

Accelerating the Welding Production Cycle

Unleashing Unmatched Welding Velocity

Laser wire welding operates at speeds that leave conventional arc welding processes like TIG or MIG in the dust. The concentrated energy source allows for rapid travel speeds, and the synchronized wire feed ensures the joint is filled consistently at this high pace. This direct translation of speed into shorter cycle times means that manufacturers can achieve significantly higher output from the same floor space, meeting tight production deadlines and increasing overall capacity without expanding the physical footprint of the operation.

Automating the Welding Cell for Hands-Free Operation

The automatic wire supply is the critical linchpin in creating a fully automated welding work cell. It completes the loop in a robotic laser welding system, allowing for uninterrupted, lights-out manufacturing. In these environments, the robotic arm manipulates the welding head and wire nozzle along complex paths for hours on end, with zero fatigue and absolute consistency. This drastically reduces direct labor costs and mitigates the challenges associated with finding and retaining highly skilled human welders for repetitive or hazardous tasks.

Minimizing Post-Welding Processing

A significant, yet often overlooked, time sink in manufacturing is post-weld finishing. Due to the precise nature of the process, laser welds with wire feed are characterized by their excellent bead appearance and minimal spatter. This often means that the welded component requires little to no grinding, polishing, or cleanup before moving to the next assembly stage. The elimination of this secondary processing step further compresses the total manufacturing lead time and reduces consumption of consumables like grinding discs, while also saving on associated labor costs.

Calculating Welding’s True Cost-Per-Weld

De-Skilling the Welding Operation

In a traditional welding setup, the quality of the weld is intrinsically linked to the skill, experience, and steady hand of the welder. With a programmed laser wire feeding system, the process is governed by digitally set parameters—laser power, travel speed, and wire feed rate. Once these parameters are optimized and locked in, the system replicates the perfect weld every time, with minimal intervention. This reduces dependency on master welders, lowers training overhead, and eliminates quality fluctuations caused by human variability.

Conserving Welding Materials and Energy

The focused beam of a laser welder is incredibly efficient, depositing energy exactly where it’s needed with minimal loss to the surrounding area. This results in significantly lower heat input and energy consumption compared to arc welding. Concurrently, the automatic feeder provides wire on-demand, virtually eliminating the stub loss and waste common in manual welding. This precise conservation of both utilities and materials contributes directly to a greener and more cost-effective operation.

The Long-Term Welding Investment Payoff

It is true that the initial capital outlay for a laser welder with an automatic wire feeder is higher than that for a conventional setup. However, a true cost analysis must look beyond the purchase price. The dramatic improvements in first-pass yield, the massive gains in production throughput, the reduction in scrap and rework, and the savings on labor and consumables combine to deliver an exceptionally compelling return on investment (ROI) over time. This makes it not just an expense, but a strategic investment in manufacturing competitiveness.

Expanding Welding Application Boundaries

Welding Complex 3D Contours

The marriage of a multi-axis robot with a laser wire feeding head breaks the constraints of linear or simple curved welds. This combination can effortlessly follow and weld along intricate three-dimensional contours, maintaining perfect torch attitude and wire placement throughout the path. This is indispensable for applications in the aerospace, automotive, and mold-making industries, where complex geometries are the norm, not the exception.

Welding a Universe of Materials and Thicknesses

This technology provides a remarkable breadth of application. For thicker materials, the addition of wire allows for a single-pass full-penetration weld that would be impossible with autogenous laser welding, avoiding the need for multiple layers. It also reaffirms its unique advantage when dealing with highly reflective materials like copper and aluminum alloys, as the wire absorbs the laser energy more readily, stabilizing the process. The ability to join dissimilar materials, as mentioned, opens up entirely new design possibilities.

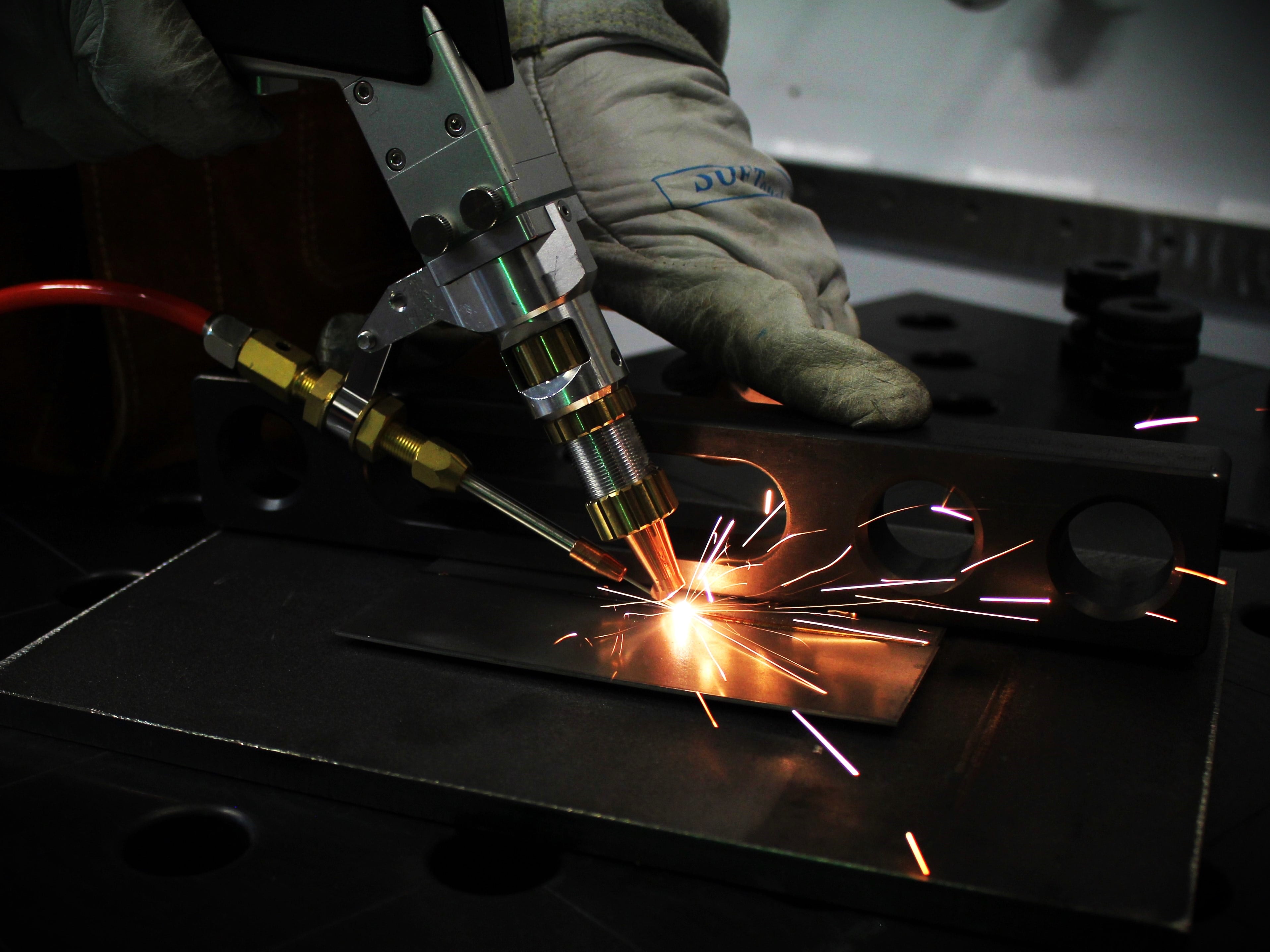

The Premier Solution for Weld Repair and Reclamation

Beyond new production, laser wire feeding is revolutionizing the repair and remanufacturing sector. It allows for the precise, low-heat-input deposition of material onto worn or damaged components, such as injection molds, turbine blades, or heavy-duty gears. The resulting repair is strong, metallurgically sound, and causes minimal distortion, often restoring the part to a condition better than new, thereby saving enormous replacement costs.

Achieving Unprecedented Welding Process Command

The Digitalization of Welding Parameters

In this system, every critical aspect of the weld is digitized. There are no ambiguous “feel” or manual adjustments. Laser power, travel speed, wire feed rate, and even gas flow are all pre-programmed and digitally controlled. This ensures that the ten-thousandth weld is physically identical to the first, guaranteeing perfect repeatability and eliminating the batch-to-batch variations that can plague manual processes.

Enabling Proactive Weld Monitoring and Traceability

Summary

In summary, the integration of an automatic welding wire supply with a laser welder is not merely an incremental improvement; it is a transformative leap forward. It delivers revolutionary enhancements across five critical dimensions: Weld Integrity, Production Speed, Cost-Per-Weld, Application Flexibility, and Process Command. As we march deeper into the age of Industry 4.0 and smart manufacturing, this highly automated, digitally native, and data-rich welding solution is poised to become the standard for any operation serious about quality, efficiency, and competitiveness. We encourage manufacturers facing welding challenges to not just read about this technology, but to actively evaluate and experience it. Ready to unlock these benefits in your own facility? Partner with us to design the ideal laser welding system for your needs.