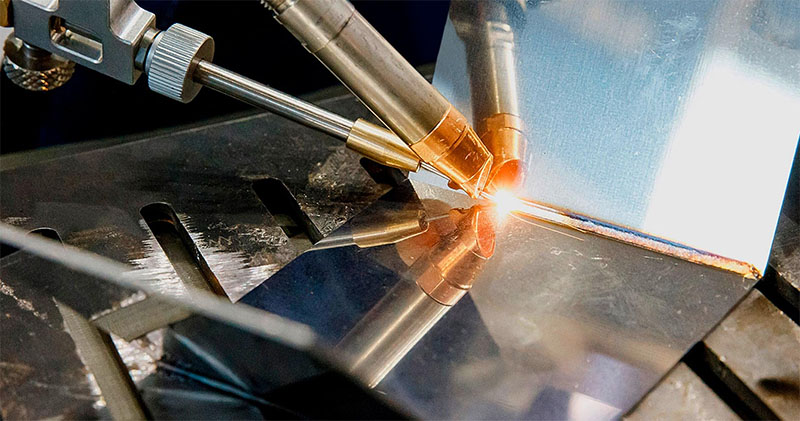

In modern manufacturing, laser welding technology is rapidly replacing traditional spot welding processes. This shift stems from the remarkable advantages of laser welding: it delivers superior precision, enhanced quality, and greater reliability. For companies committed to manufacturing excellence, understanding how laser welding improves production efficiency and reduces costs is a crucial first step toward technological advancement.

Precision Welding: Exceptional Quality at a Microscopic Scale

Laser welding sets a new standard for microscopic precision and impeccable weld quality.

Ultra-High Precision

Laser welding achieves positioning accuracy down to 0.1 mm and creates smaller weld spot diameters of 0.2-0.6 mm. This makes it ideal for processing delicate parts in industries requiring extreme precision, such as medical devices, microelectronics, and aerospace, where minute tolerances are critical.

Smaller Heat-Affected Zone (HAZ)

The process uses a highly concentrated heat source, resulting in a Heat-Affected Zone (HAZ) up to 50% smaller than conventional spot welding. This significantly minimizes thermal distortion and stress, preserving the dimensional stability of precision components and often eliminating the need for post-welding machining.

Excellent Weld Quality

Characterized by a rapid thermal cycle, laser welding promotes a fine-grained microstructure that enhances mechanical strength. The process also significantly reduces defects like porosity, producing exceptionally clean seams with minimal spatter and oxidation for high-integrity, reliable joints.

Efficient Welding: Automation-Driven Superior Productivity

Laser welding is not just a leap in speed, but a bridge to intelligent, high-efficiency production.

Faster Welding Speeds

Optimizing laser parameters enables speeds 17%-60% faster than TIG or spot welding, with line rates over 7.5 m/min. This directly increases output per shift and shortens lead times, meeting high-efficiency demands.

Seamless Automation Integration

The systems integrate seamlessly with robots and vision systems for stable 24/7 operation and adaptive welding. Cycle times are 4-5 times faster than spot welding, significantly boosting Overall Equipment Effectiveness (OEE).

Drastic Reduction in Post-Processing

The process produces clean, spatter-free welds, eliminating post-weld steps like grinding and cleanup, which saves labor and time. Quick changeovers further reduce downtime, enabling flexible manufacturing.

Flexible Welding: Breaking Material and Geometric Constraints

Laser welding breaks the limitations of traditional welding in terms of geometry and material combinations.

Broad Material Compatibility

Laser welding joins a wide range of metals, including stainless steel, aluminum, and highly reflective materials like copper and titanium. A key advantage is its ability to create high-quality dissimilar material joints, such as copper-to-aluminum, offering greater design freedom for complex products.

Adapts to Complex Geometries

The process produces deep, narrow welds with a high aspect ratio, suitable for complex joints inaccessible to spot welding. It enables stake welding through lap joints and is widely used in precision applications like miniature electronics sealing and jewelry manufacturing.

Portable Solutions

Portable laser welders break the constraints of fixed stations, enabling on-site repairs and small-batch production in remote facilities, large structures, and workshops. This significantly enhances operational flexibility and saves logistics costs.

Robust Welding: Superior Strength and Exceptional Reliability

Laser welding doesn’t just join materials; it creates components with superior performance.

Higher Mechanical Strength

Independent tests confirm laser-welded joints offer 9.5% to 14.5% higher tensile-shear strength than traditional resistance spot welds. This results from deeper penetration and more homogeneous material fusion, providing superior fatigue resistance and making it the preferred choice for manufacturing lighter, stronger components in automotive and aerospace.

Improved Microstructure and Hardness

The extremely rapid cooling rate in laser welding promotes the formation of a fine-grained structure in the weld zone. This refined microstructure yields higher peak hardness, resulting in superior wear resistance and durability, ideal for tools and critical machinery components.

Extremely Low Defect Rates

The process inherently produces minimal porosity and spatter. Coupled with real-time monitoring systems that make instant corrections, it achieves up to 70% lower defect rates versus manual spot welding. This high consistency is critical for safety-critical applications like medical implants and airbags.

Economical & Green Welding: Lower Operational Costs and Support for Sustainable Development

Laser welding is a smarter, more economical investment that also supports sustainability goals.

Energy Savings up to 60%

Laser welding converts more electricity into effective heat, consuming 30-50% less energy per weld than resistance spot welding. A single station can save up to $15,000 annually in electricity costs, achieving both cost reduction and sustainable manufacturing.

Reduced Footprint

A standard fiber laser setup requires only about 1.5 m², versus 3-5 m² for traditional spot welding. This compact design enables denser production lines, freeing up valuable space in constrained manufacturing environments.

Cleaner and Greener Process

The process generates up to 70% fewer metal fumes and typically requires no filler materials. It also avoids toxic by-products like slag, aligning with green manufacturing principles by reducing hazardous waste.

Summary

In summary, upgrading from traditional spot welding to laser welding represents a strategic investment worth making. It demonstrates significant advantages in precision, efficiency, flexibility, and reliability, while also being a more environmentally friendly option. These benefits directly translate into competitive advantages for your business, helping you produce higher quality products while achieving cost reduction and efficiency improvement.

Contact us today to discover how our laser welding solutions can create value for your business!