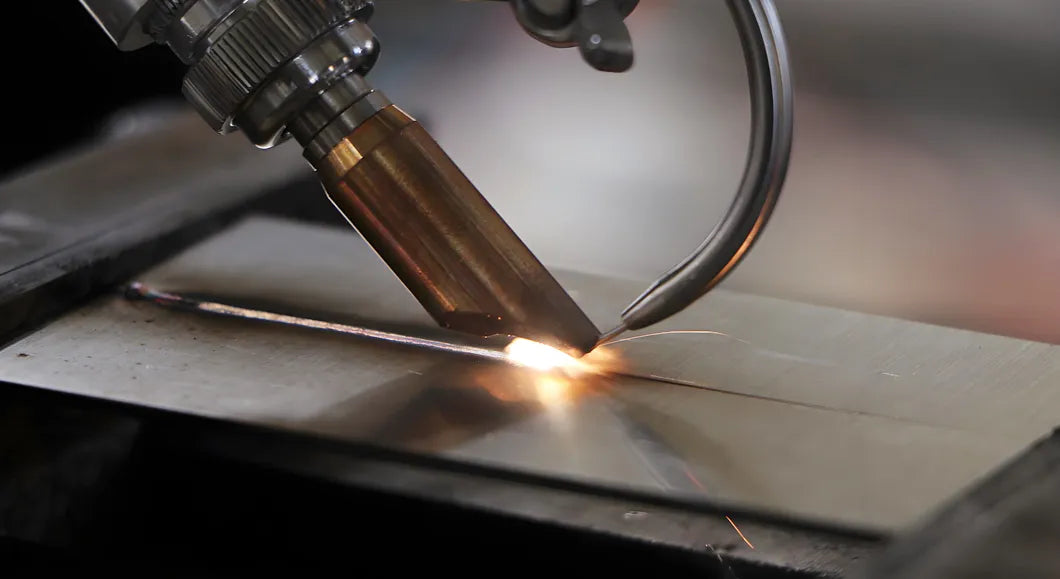

Laser welding is a highly precise technology, yet it demands exceptional consistency in materials. The welding wire is far more than just filler metal; it is a key factor determining weld quality. Using poor-quality wire can lead to defects and undermine the laser’s advantages. To achieve optimal results, a complete system approach is essential: combining a precision laser with high-quality wire and reliable feeding technology. Investing in superior welding wire is critical for ensuring stable, reliable, and high-quality welds.

How Bad Welding Wire Leads to Major Welding Problems

Low-quality welding wire acts as a catalyst for failure. Each deviation from ideal specifications manifests as a specific, costly defect in the weld.

Unreliable Diameter

Diameter inconsistency is a primary source of process instability. Wire that is too thick absorbs excessive energy from the laser welder, creating an oversized and turbulent melt pool that can lead to burn-through, while wire that is too thin may vaporize unevenly or inadequately fill the joint. Most critically, variation within a single spool causes fluctuating heat input, producing an irregular weld bead. This directly leads to inconsistent penetration, fusion defects, and weak points—compromising structural integrity.

Impure Composition

The wire must have precise chemistry and high material purity. Surface contaminants such as oil, grease, or rust vaporize under the laser, introducing gases that create porosity. Internally, excessive impurities like sulfur and phosphorus promote hot cracking and reduce toughness. Even slight deviations in key alloying elements, for example silicon or manganese, can alter the weld metal’s properties, leading to brittleness or poor corrosion resistance. In essence, a contaminated wire poisons the weld.

Material Mismatch

Using a wire not designed for the base material is a fundamental error. A significant mismatch in alloy composition or thermal properties like melting point prevents proper metallurgical bonding, potentially resulting in lack of fusion along the joint edges. More critically, it creates weld metal with incompatible mechanical properties, making the weld the weakest point—prone to cracking under stress or rapid corrosion. The weld must act as an extension of the base metal, not its adversary.

Poor Feedability

Laser welding operates with a tiny focal spot, requiring the wire to reach this exact point with consistent and steady precision. A wire with poor surface characteristics such as roughness, inadequate straightness due to coil memory, or low column strength will not feed smoothly. It may buckle, jam, or deflect, causing the wire tip to wander. This misplacement leads to irregular fusion, weld gaps, or interference with the laser beam, resulting in spatter and process instability. Even the most advanced laser is ineffective if the wire cannot achieve reliable feeding and precise delivery accuracy.

How Premium Welding Wire Leads to Perfect Welds

High-quality welding wire transforms the process from a battle against variables into a model of repeatability. It is the enabler of the laser’s full potential.

Delivering Unmatched Process Stability

Premium wire is engineered to ensure flawless feeding, with consistent diameter, excellent straightness, and ideal surface lubrication allowing it to glide smoothly through the feeder and into the laser welding machine’s focal point. This seamless delivery eliminates stoppages, reduces operator intervention, and enables higher feed rates—making operational stability the foundation of efficiency in automated production.

Ensuring Flawless Weld Metallurgy and Appearance

By eliminating variables like contamination and inconsistency, quality wire enables the laser to form a pure, controlled melt pool. This produces a uniform, smooth weld bead with consistent shape and appearance. Most importantly, it ensures defect minimization, drastically reducing porosity and solidification cracking to create a weld that is sound both internally and externally.

Guaranteeing Specified Mechanical and Corrosive Performance

A wire from a reputable manufacturer comes with certified quality and guaranteed mechanical properties. When correctly matched to the base metal, it produces a weld joint that meets or exceeds design requirements for strength, ductility, and toughness. For corrosive environments, the weld’s composition ensures reliable performance in harmony with the parent material, maintaining the integrity of the assembly throughout its service life.

Five Golden Rules for Choosing Premium Welding Wire

Choosing the correct wire is a strategic decision. Follow these rules to ensure optimal performance.

Rule 1: Match Composition and Performance to the Base Metal.

This is non-negotiable. Adhere to the principle of “like joins like” for standard applications—for example, use an ER70S-6 wire for mild steel and 308L for 304 stainless steel. For advanced materials or specific performance needs, such as enhanced strength or crack resistance, select a wire specifically engineered for that purpose, even if its alloy differs, such as choosing a nickel-based wire for joining dissimilar metals or cast iron.

Rule 2: Demand Tight Diameter Tolerance and Lot-to-Lot Consistency.

Do not just look at the nominal diameter such as 1.0mm, but scrutinize the guaranteed tolerance—for example, tighter tolerances like ±0.01mm are superior to ±0.05mm. More importantly, ensure the supplier can demonstrate batch-to-batch consistency. This stability is what allows you to lock in a perfect set of parameters and run them indefinitely.

Rule 3: Prioritize Superior Surface Cleanliness and Straightness.

Specify wire with a clean finish, free from oily residues. For critical applications like aerospace or automotive, consider copper-free coated wires to prevent volatile copper contamination. The wire must also have excellent geometric stability, including its natural curve from the spool and tendency to spiral, to ensure it feeds straight and precisely into the laser’s focal point.

Rule 4: Trust in Certification and Proven Brand Reputation.

Always source wire from established manufacturers with strong reputations. Require full material certifications that trace chemical and physical properties back to the production lot, and look for recognized industry certifications such as AWS, EN, TÜV, or Lloyd’s Register as independent validation of quality standards. A brand’s reputation is ultimately built on the consistent reliability of its wire in real-world applications.

Rule 5: Optimize Your Entire Welding System

True laser welding excellence requires an optimized, integrated system where all components work in harmony. The finest wire alone cannot compensate for a mismatched setup. This means choosing a laser welder with precise beam control and stable output, pairing it with a high-accuracy wire feeder that ensures smooth, synchronized delivery, and sourcing both your equipment and consumables from a single trusted partner. Working with an integrated supplier like MAXWAVE simplifies validation and guarantees compatibility, ensuring your system—from the laser and feeder to the certified wire—is tuned to deliver consistent, high-quality results from the start.

Conclusion

In laser welding, every component matters. The welding wire is essential for delivering both material and quality. Using inferior wire wastes the value of advanced laser equipment. Achieving flawless results requires treating your welding setup as one integrated system—where the laser, feeder, and wire work in perfect harmony.Ready to see how a fully synchronized system performs?Contact MAXWAVE today. Our experts will help you choose not only the best welding wire, but also the right laser welding and feeding solutions to achieve unmatched consistency, speed, and quality in your work.