Structural Welder

Structural welders are responsible for assembling and welding the steel frameworks that form the backbone of buildings, bridges, and other large infrastructure projects. This work often involves operating at considerable heights, introducing significant risk and demanding strict adherence to safety protocols.

Typical Work Settings

Structural welders are primarily employed on construction sites and civil engineering projects, such as those for skyscrapers and stadiums. The work environment is frequently outdoors and can involve hazardous or elevated locations, requiring constant vigilance.

Essential Skills and Certifications

Proficiency in Shielded Metal Arc Welding (SMAW) and Flux-Cored Arc Welding (FCAW) is essential, alongside the ability to accurately read and interpret complex construction blueprints. Key certifications include OSHA safety training and familiarity with the AWS D1.1 Structural Welding Code to ensure all work meets rigorous industry standards.

What Makes Structural Welding Unique

This career is defined by large-scale, high-stakes projects where precision and structural integrity are absolutely non-negotiable. These welders play a crucial role in ensuring the safety and durability of major infrastructure used by thousands of people every day, offering a strong sense of accomplishment from seeing their work become part of a city’s skyline.

Underwater Welder

Underwater welders combine advanced welding expertise with commercial diving skills to repair, maintain, and construct marine structures. Their work is critical for the shipping, oil and gas, and infrastructure maintenance industries, ranking it among the most challenging and specialized welding fields.

Where Underwater Welders Work

Their work sites are as varied as the marine environment itself, encompassing oceans, rivers, and lakes. They are employed to repair ships and submarines, maintain underwater pipelines on offshore oil platforms, and restore critical civil infrastructure like bridges and dams.

Core Skills and Required Certifications

This role requires a commercial diving license from an organization like the ADCI, an AWS-approved underwater welding certification, and extensive emergency procedure training. Mastery of specialized techniques for welding in aquatic conditions is fundamental.

What Sets Underwater Welding Apart

The role is characterized by high risk and high reward. Salaries reflect the extreme conditions and specialized skills, typically ranging from $50,000 to over $150,000 per year. Welders face unique hazards such as decompression sickness, electric shock, and limited visibility, making uncompromising safety procedures paramount. Many in the field are drawn by the adventure and extraordinary experiences, balanced against the intense physical and mental demands.

Aerospace Welder

Aerospace welders play a specialized role in building and repairing aircraft, spacecraft, and related components where absolute precision and safety are essential. These professionals work with materials like titanium, aluminum, and exotic alloys, demanding top-level welding expertise and strict adherence to quality standards.

Work Environment & Industries

Employment is found with aerospace manufacturers, defense contractors, and maintenance organizations. The work is conducted indoors in highly controlled settings like cleanrooms, with strict regulations on temperature, humidity, and contaminants to ensure the integrity of every weld.

Essential Skills and Certifications

Expert-level proficiency in TIG welding and other precision methods is mandatory, along with deep knowledge of advanced alloys. Certifications from the AWS or NADCAP accreditation are standard, as is the ability to interpret detailed aerospace blueprints.

What Makes Aerospace Welding Unique

The field is governed by exceptionally stringent quality standards that far exceed those in most other industries. This responsibility is matched by high earning potential, often between $65,000 to $100,000 , and clear paths for advancement into inspection or supervisory roles. It attracts individuals passionate about technology and innovation who thrive under pressure.

Why Aerospace Welding Demands Excellence

- Jobs frequently include fabricating components for space shuttles, satellites, or military jets, where a single flaw can lead to mission failure.

- The role combines hands-on technical work with a constant focus on innovation and safety—making it ideal for welders who thrive under pressure and embrace ongoing training.

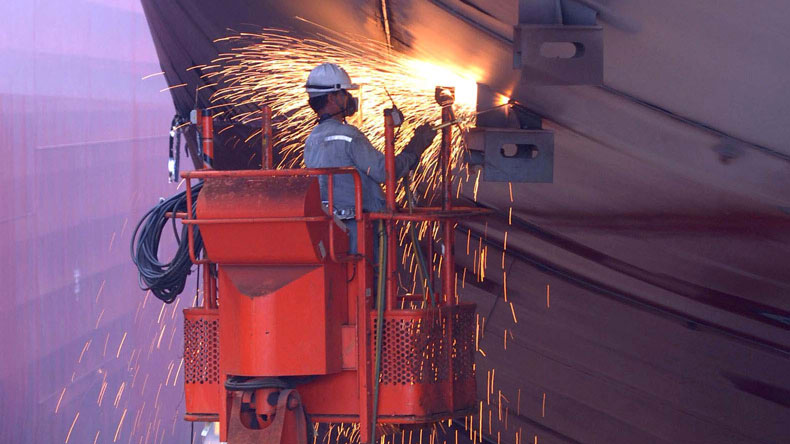

Shipyard Welder

Shipyard welders are responsible for building, repairing, and maintaining ships, barges, and other marine vessels. Their work is vital to the maritime, shipping, and naval industries, making them essential to transportation and defense infrastructure.

Typical Shipyard Welding Work Environment

The work occurs in large shipyards, both outdoors and within massive dry docks or fabrication halls. Conditions are often humid, noisy, and physically demanding, sometimes involving work in cramped confined spaces like ship hulls.

Essential Shipyard Welder Skills and Certifications

A broad skill set in MIG, TIG, and flux-cored arc welding is required, complemented by the ability to read marine schematics. AWS certifications and specific shipyard safety training are essential for navigating the unique hazards of the environment.

Distinct Aspects of Shipyard Welding

Why Shipyard Welding Is a Key Welding Career

- Shipyard welders contribute to national transportation, global trade, and defense.

- The work blends technical problem-solving, manual skill, and a strong culture of safety.

- Those who enjoy working with their hands on large-scale projects often find shipyard welding to be both challenging and rewarding.

Welding Engineer

Welding engineers design, develop, and oversee welding processes and procedures that ensure the strength, safety, and efficiency of welded structures and products. They bridge the gap between design and practical fabrication, combining materials science with advanced engineering principles.

Typical Work Environments & Industries

They work across diverse industries including automotive, aerospace, and construction. Their time is split between offices, laboratories, and manufacturing or construction sites, where they troubleshoot procedures and ensure compliance with standards.

Essential Skills and Certifications

The role demands a bachelor’s degree and often a Certified Welding Engineer (CWEng) certification. Key skills include deep knowledge of welding techniques, metallurgy, project management, and a thorough understanding of codes from AWS, ASME, and ISO.

What Makes the Welding Engineer Career Unique

This position carries high-level responsibility for the safety and cost-effectiveness of major projects. Salaries reflect this, ranging from $60,000 for entry-level roles to over $120,000 for experienced engineers. It is a career focused on innovation, involving robotics and new materials, ideal for those who want to lead and have a significant technical impact.

Why Welding Engineering Is Essential

- Welding engineers ensure welding practices meet technical and safety standards, prevent failures, and drive innovation across multiple industries.

- Their expertise enables the construction of everything from bridges and oil pipelines to aircraft, satellites, and new green technologies.

- The role is ideal for those who want to combine a passion for engineering with tangible, real-world impact.

Pipefitter welder

Pipefitters are skilled tradespeople who fabricate, assemble, install, and repair piping systems that carry water, steam, chemicals, oil, or gases in industrial, commercial, and power plant settings. Their expertise combines welding, blueprint reading, and precise measurement to ensure complex piping networks are safe, efficient, and reliable.

Typical Work Environments for Pipefitters

They work in diverse locations such as oil refineries, chemical plants, power stations, and large commercial buildings. The environment is physically demanding, often involving tight spaces, elevated work platforms, and exposure to high temperatures or hazardous materials.

Essential Pipefitter Skills and Industry Certifications

Proficient in TIG, MIG, and stick welding for pipes; Ability to read piping schematics and isometric drawings; OSHA certification and confined space training; AWS or ASME pipe welding certifications.

What Sets Pipefitting Apart

Pipefitters solve critical challenges to keep industrial operations running smoothly. The work is highly varied, with each site presenting unique problems. Experienced pipefitters can earn $55,000–$90,000, with travel and overtime on shutdown projects offering substantial additional compensation. The job appeals to those who enjoy hands-on problem-solving on essential systems.

Industrial Maintenance/Shutdown Welder

Industrial maintenance and shutdown welders are relied upon to repair, upgrade, and maintain heavy industrial equipment during scheduled plant shutdowns or emergency outages. Their expertise ensures factories, refineries, power plants, and processing facilities can resume operations quickly and safely—minimizing downtime costs.

Where Industrial Maintenance/Shutdown Welders Work

They are employed in factories, refineries, power plants, and processing facilities. The work is fast-paced, often conducted in confined spaces, around heavy machinery, and during extended shifts to meet tight turnaround schedules, frequently requiring travel to different sites.

Essential Skills and Required Certifications

Advanced skills in multiple welding processes are needed for repairing complex equipment like pressure vessels and piping. Quick problem-solving abilities and certifications in safety procedures like lockout/tagout and confined space entry are non-negotiable.

Unique Challenges and Rewards of Shutdown Welding

This niche is known for high earning potential, often exceeding $100,000 annually due to premium overtime and hazard pay. The demand for skilled welders who can perform under pressure provides excellent job security. While the work is physically and mentally taxing with long hours, it offers great satisfaction from solving complex problems and keeping critical industries operational.

Welder Fabricator

Fabricators are skilled welding professionals who take raw metal materials and transform them into finished products, structures, or subassemblies through a mix of cutting, welding, and assembly techniques. This role is central to custom manufacturing and industrial production where parts must be made exactly to spec.

Typical Work Environment & Industries

They typically work indoors in fabrication shops or manufacturing plants equipped with welding stations, CNC cutters, and press brakes. The projects are diverse, ranging from custom staircases and machinery frames to industrial enclosures.

Essential Fabricator Skills and Certifications

Proficiency in MIG, TIG, and stick welding is required, along with the ability to read detailed fabrication drawings and blueprints. AWS certifications and precision measurement skills are highly valued.

What Makes Fabrication Welding Unique

This role emphasizes creativity and custom metalwork, appealing to those who enjoy building tangible products from scratch. Fabricators typically earn between 70,000, with opportunities to advance into supervisory positions or specialize in areas like CNC operation. The job satisfaction comes from seeing a project through from plan to completion.

Oil Rig Welder

Oil rig welders are highly skilled professionals who perform welding work on offshore drilling platforms and support vessels. Their expertise is essential for the safe construction, maintenance, and repair of oil rigs, pipelines, and various maritime structures operating in remote, high-pressure environments.

Oil Rig Welder Work Environment & Industries

They work on offshore oil platforms, often hundreds of miles at sea. Conditions are harsh, exposed to saltwater, wind, and heavy machinery, with shifts commonly following a rotation of 14-28 days on the rig followed by equal time off.

Core Skills and Required Oil Rig Welder Certifications

Expert welding skills for harsh marine conditions are required, along with critical safety certifications like BOSIET (offshore survival) and HUET (helicopter escape). Knowledge of specific codes like AWS D3.6 is standard.

Unique Aspects of Oil Rig Welding

This is one of the highest-paying welding careers, with salaries ranging from $70,000 to over $150,000, boosted by overtime and offshore bonuses. The job involves significant time away from home and inherent risks, but offers substantial financial reward and a strong team camaraderie for those suited to the lifestyle.

Personal Perspectives and Career Outlook

- Many oil rig welders enjoy the challenge of high-stakes, high-reward work and the camaraderie of working with tight-knit teams. The long periods away from home and the demanding schedule can be tough but are often balanced by exceptional pay and extended time off.

- Career progression can lead to supervisory roles, welding inspector positions, or specialized offshore project management. Certifications and offshore experience are highly valued around the world, opening opportunities with international drilling companies.

Tool and Die Maker with Welding Expertise

Tool and die makers are highly skilled welding professionals who design, fabricate, and repair precision tools, dies, molds, and specialized components used in manufacturing. Their expertise ensures the accuracy and efficiency of mass production in industries from automotive to electronics.

Typical Work Environment & Industries

They work in toolrooms and machine shops within manufacturing plants, utilizing equipment like CNC mills, lathes, and precision welding stations to build and repair critical components.

Essential Tool and Die Maker Skills and Certifications

The role requires exceptional precision welding skills, often including micro-welding, and the ability to interpret complex engineering drawings. Completion of an apprenticeship and certifications from bodies like NIMS are typical pathways.

Earnings, Career Path, and Personal Perspectives

- Salary Range: In the U.S., tool and die makers typically earn between $48,000 and $85,000 annually. Highly experienced or specialized professionals, especially those with advanced CNC skills or working in the aerospace/medical industries, can exceed this range.

- Demand: Tool and die makers remain in steady demand due to ongoing needs for custom tooling in advanced manufacturing, including the rise of automation and robotics.

- Job Security & Advancement: With experience, many advance to supervisory roles, toolroom management, or move into high-level CNC programming and design. Some choose to open independent tool and die shops, serving niche manufacturing clients.

- Personal Opinions: Many tool and die makers enjoy the intellectual challenge of building critical, high-precision parts and solving complex manufacturing problems. The satisfaction of seeing production lines run smoothly thanks to their work is frequently mentioned. However, the pressure to maintain quality under strict deadlines, and the constant need for technical skill upgrades, can be demanding.