I’ve often thought about how we can clean things. Can we do it without hurting our planet or using strong chemicals? I find laser cleaning machines really interesting. In my opinion, they offer a smart, earth-friendly way to clean. They protect materials. Plus, they help reduce waste. From my perspective, there’s something about these machines that many people don’t notice. I believe this overlooked detail could boost their green advantages even more.

What Is A Laser Cleaning Machine?

Based on my experience, a laser cleaning machine is an advanced tool. It uses focused laser light to remove unwanted materials from surfaces. These materials can be rust, paint, coatings, and other residues on different items. I believe this machine uses sophisticated laser technology. This makes it a non-contact and precise cleaning method. I also appreciate that it’s a green alternative to older cleaning techniques, such as abrasive blasting or chemical removal.

Key Features I’ve Observed in Laser Cleaning Machines

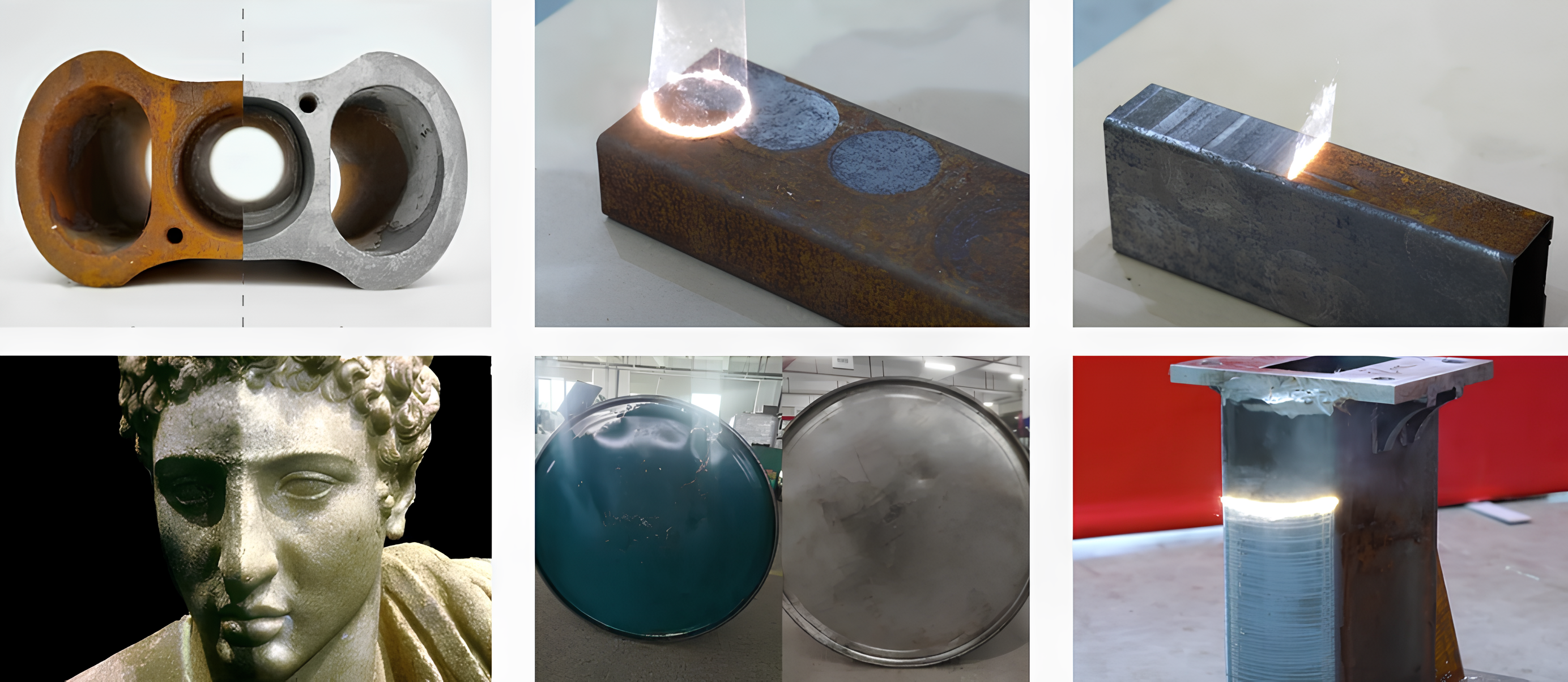

Applications: I’ve seen laser cleaning machines work well on many things. You can use them on metals, stone, old artifacts, and even delicate surfaces. People use them a lot in aerospace and electronics. I also know they are popular in restoring cars and preserving heritage items.

How It Works: From what I understand, the system shoots a strong laser beam at the dirt or coating. This unwanted layer soaks up more laser energy than the material underneath. Then, this top layer turns into vapor or gets blasted off by heat and shock. I think it’s clever how the main material stays safe and unharmed.

Non-Contact and Kind to the Environment: I like that these machines don’t wear down the surface or the tool itself. Plus, you don’t need chemicals or abrasive materials. This means less waste is created. I believe this greatly lessens the impact on our environment.

Main Components I’ve Noticed in a Laser Cleaning Machine

- Laser Generator – This part creates the laser beam.

- Optical System – This system aims and focuses the beam on the surface.

- Control System – With this, I can adjust settings. These include power, how long the pulse lasts, and how often it pulses.

- Cooling System – This is important. It keeps the machine at a safe temperature, especially when I use it for a long time.

Power Ranges and How They Perform, In My View

Low Power (20W–100W): I find these perfect for taking off light rust or cleaning small areas.

Medium Power (200W–300W): I recommend these when you have a medium amount of buildup.

High Power (up to several kW): For big industrial jobs, like getting rid of thick coatings or a lot of rust, I’d go with these.

As an example, I’ve seen a 100W pulsed fiber laser cleaning machine work wonders. It can shoot out quick bursts of power up to 10,000W. This removes rust or paint from metal very well, and I like that it doesn’t harm the material underneath.

Types and Sizes I’ve Encountered

I’ve seen laser cleaning machines in a few different forms: – Handheld Models: These are small and easy to carry. They start at a few tens of watts. I find them good for cleaning on location or for precise jobs. – Automated Systems: These are bigger, often robotic. Factories can build them into their production lines. I understand they provide steady power, sometimes several kilowatts, for tough industrial work.

Cleaning Speed and How Well They Work

From what I know, pulsed fiber laser systems are fast. They can fire 5,000 to 200,000 laser pulses every second. The size of the laser spot is usually from a tiny fraction of a millimeter up to about 2 mm. I’ve learned that scanning speeds can be 5–10 meters per second. Some special systems can even go faster than 20 meters per second for quick cleaning tasks.

Benefits for the Environment, As I See It

I believe laser cleaning is a solution that’s kind to our planet. It mainly creates vapor from the impurities and very little solid trash. What I really appreciate is that you don’t need chemicals or rough materials.

My Summary: So, in my opinion, laser cleaning machines offer a very exact, quick, and flexible way to clean many types of materials. I think people are choosing them more and more for today’s factory and preservation jobs. This is because they are useful in many situations, safe, save money, and don’t harm the environment much.

How I See Laser Cleaning Machines Work

From my experience, laser cleaning machines use laser ablation. This process cleans contaminants from surfaces. The great part is, it doesn’t damage the material underneath. I’ll explain how this works in more detail:

The Laser Cleaning Process Step by Step, As I Understand It

- First, a machine aims a focused laser beam at a specific frequency onto the dirty surface. You might use a handheld tool or automated machinery for this.

- Things like rust, paint, or oil—these are the contaminants—soak up the laser energy. They do this much better than the actual material itself.

- This layer of contaminant absorbs energy very fast. It heats up in just nanoseconds. Then, it can vaporize, crack, or its molecular bonds might break. This action pushes off and gets rid of the unwanted stuff.

- The main material, like metal, stone, or even delicate old surfaces, isn’t harmed. In my view, this happens because it can withstand more energy before showing damage. I believe this is vital for jobs needing precision and care.

Core Ways Laser Cleaning Works, In My Opinion

Thermal ablation: The contaminant heats up fast. Then, it turns into vapor.

Photomechanical effects: The layer heats and expands suddenly. This makes it crack and fall off.

Photochemical reactions: Strong light breaks the chemical connections inside the contaminant layer.

My Favorite Unique Features and Its Green Benefits

Non-contact precision: I like how the very focused beam cleans tricky surfaces and tiny or tough spots. You can also adjust the power and focus settings for each specific job without trouble.

Minimal waste: Most unwanted stuff just vaporizes straight away. This means there’s almost no solid waste. I also appreciate that there’s no chemical mess left behind.

No abrasion: It doesn’t scrape the surface like sandblasting or harsh chemicals do. So, the original surface stays safe. I think this makes laser cleaning great for valuable or delicate items.

Industrial Uses and How It Performs, From My Perspective

Many uses: I see it remove rust from steel. It can strip paint from cars and planes. It also cleans oil or oxides when making electronics.

Fast work: Laser pulses are super quick, working in nanoseconds to milliseconds. Industrial systems can have power from a few tens of watts up to several kilowatts. I recommend choosing the power based on the job size and how fast you need it done.

Flexible cleaning: It can clean layers of contaminants from a few microns to several millimeters thick. How thick depends on what you’re cleaning and the machine’s settings. I find this very adaptable.

I notice laser cleaning machine is quickly taking over from older methods. This is because it works well, it’s safe for the materials underneath, and it’s good for the environment. It’s becoming the go-to choice in fields like aerospace, automotive, electronics, manufacturing, and even for preserving historical items. I believe it’s a smarter way to clean.

Summary

I’ve looked into laser cleaning machines. I think they are a big step up in cleaning. They are precise and efficient. They also have a small impact on the environment. This makes them better than old cleaning ways. Industries want things that last and are good quality. So, I feel these machines will be common in more places. I really like how they mix new tech with being good to the earth. It shows we can move forward without hurting our planet. To me, laser cleaning is more than just a factory method. I see it as a peek into a future that’s cleaner and better for the long run. For more details about laser cleaning machine or to get a quote, contact us today!