Looking to invest in a laser cleaning machine for your business in the US? With so many options on the market, it can be overwhelming to know which suppliers and manufacturers offer the best combination of performance, reliability, and value. In this guide, we break down the top 6 trusted providers in the US and beyond, helping you make an informed choice and find the right solution for your industrial cleaning needs.

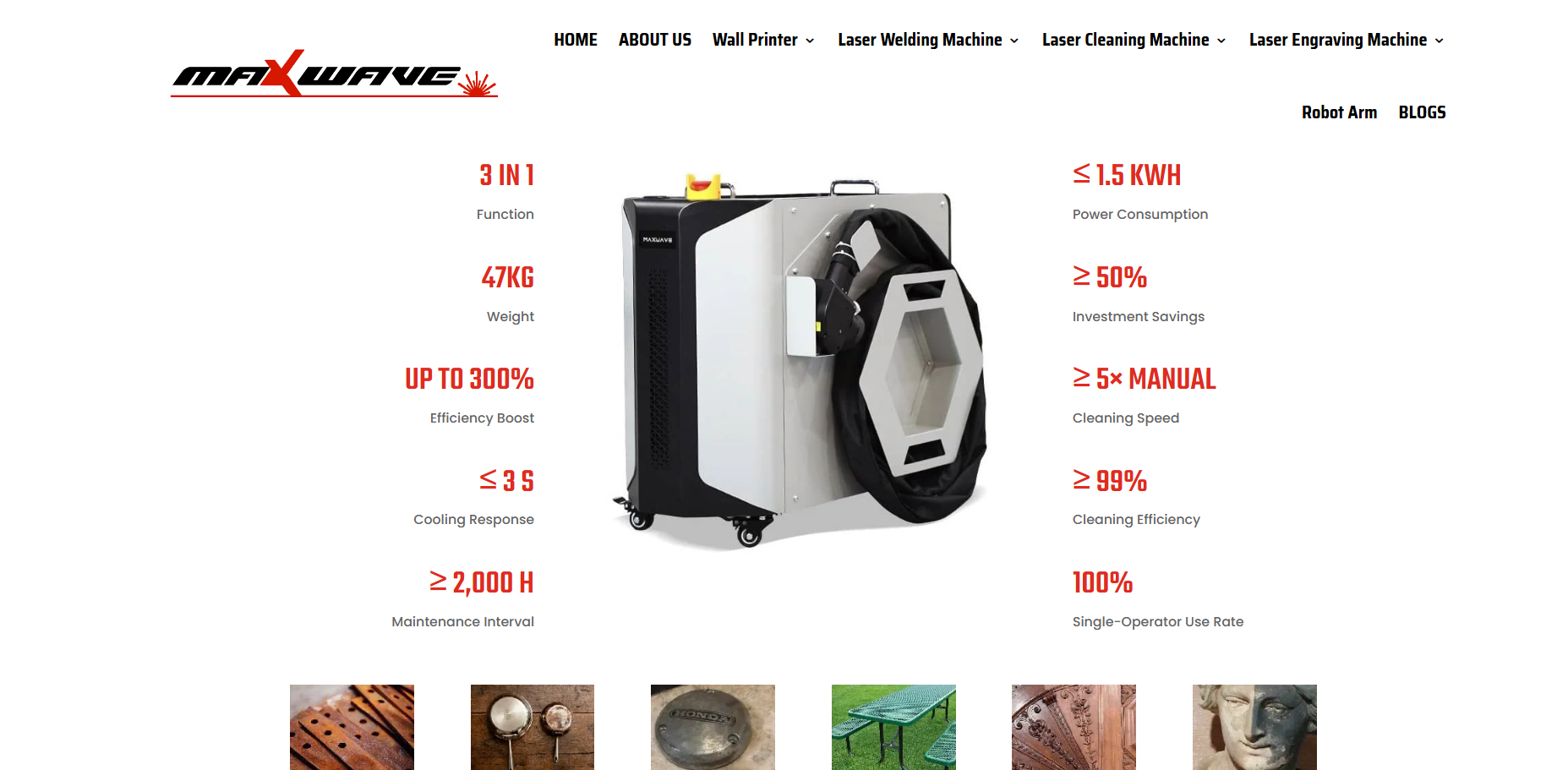

MaxWave Laser: A Top Supplier of Industrial Laser Machine for Cleaning

MaxWave Laser is a major supplier of industrial laser cleaners for the US market. Based in China, the company has a strong reputation. In my experience, they offer dependable, powerful, and affordable fiber laser solutions.

Product Range and Features

MaxWave provides handheld and small fiber laser cleaners that are ideal for removing paint, rust, oxides, and adhesives. Built with modern technology, these machines feature adjustable pulse widths, high peak power, and simple industrial controls that make them easy to operate. With 8 flexible cleaning modes, they can be adapted to handle a wide variety of materials and cleaning tasks, offering both versatility and efficiency in one solution.

Advantages of MaxWave Laser Cleaners

- Easy to Use: The operation is simple and handling is easy. This makes them suitable for operators at any skill level.

- Portability: Their light weight and small size give you more freedom to work at different job sites.

- Great Value: I find that MaxWave’s solutions give you excellent performance for the price. They also reduce downtime and need little maintenance.

- Consistent Results: The machines are made to give you precise and similar cleaning results every time, which is important for industrial work.

How to Buy MaxWave Laser Cleaning Machines in the US

MaxWave products can be purchased directly through Alibaba International, AliExpress, or the official MaxWave website, making them easily accessible to customers worldwide. In addition to convenient purchasing options, the company provides comprehensive technical support and reliable after-sales service, ensuring that customers receive the assistance they need both during and after their purchase.

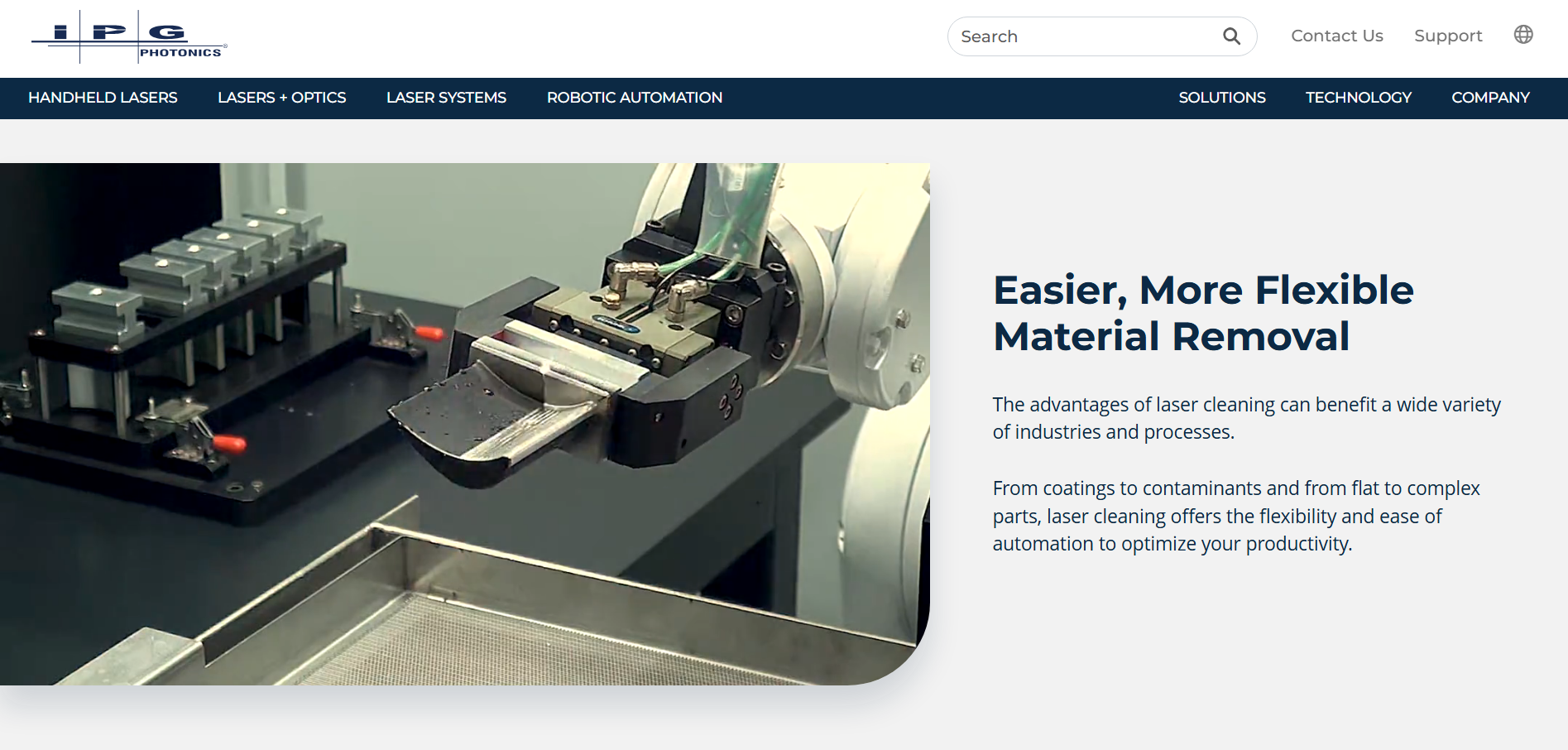

IPG Photonics: Top US Manufacturer of Fiber Laser Machine for Cleaning

IPG Photonics is based in Oxford, Massachusetts. In my opinion, they are a world leader in fiber laser technology. They are also a well-known name in the US market for laser cleaning.

Overview of IPG Photonics’ Laser Cleaning Solutions

IPG specializes in pulsed fiber lasers designed specifically for industrial cleaning, offering both circular and square beam spots along with variable pulse widths and high peak power for the fast removal of paint, corrosion, and oxides. Equipped with advanced laser control systems, their products deliver reliable performance and consistent cleaning results across different applications. Built with industry needs in mind, IPG’s solutions are engineered to withstand tough factory environments while ensuring dependable operation and highly effective outcomes.

Key Benefits of IPG’s Laser Cleaning Machine

-

High Reliability & Long Service Life: Built to last, reducing downtime and overall operating costs.

-

Energy Efficiency: Requires little to no consumables, making it more cost-effective and eco-friendly than traditional methods.

-

Precise Beam Control: Allows accurate material removal without damaging the base surface, ideal for sensitive or high-value components.

-

Low Maintenance: Designed for minimal upkeep, saving both time and resources.

How to Buy IPG Photonics Laser Machine for Cleaning in the US

From my experience, purchasing IPG Photonics laser machines for cleaning in the US is straightforward, as customers can either buy directly through the official IPG Photonics US website or work with approved distributors across the country. In addition, IPG offers comprehensive support services, providing clients with expert technical advice and quick assistance. Their team can guide businesses in selecting the right laser cleaner and ensure proper setup tailored to specific operational needs, making the buying process both efficient and reliable.

CleanLASER: Reliable German Laser Machine for Cleaning in the US

CleanLASER is a top German brand. From my experience, they focus only on laser cleaning technology. They are well-known in the United States. They offer high-tech laser cleaning systems for industrial work, business cleaning, and fixing up old items.

CleanLASER Product Range

CleanLASER offers a wide range of solutions, from portable 20W backpack-style units laser machine for cleaning that are lightweight and convenient for cleaning small or hard-to-reach areas, to high-powered 1000W systems designed for heavy-duty factory work capable of efficiently stripping thick rust and paint. In addition to individual machines, they also provide complete workstations and even custom-built systems tailored to specific cleaning or factory requirements, ensuring flexibility for different industrial applications.

Why Choose CleanLASER?

- Portability: I find that many CleanLASER models are made to be easy to carry. You can use them on-site. This makes them a good choice for jobs in one place or for jobs that require travel.

- Durability: I can tell this equipment is built to last a long time. It performs well and you can count on it, even on difficult job sites.

- Versatility: These systems are very flexible. You can use them for soft cleaning on historic items. You can also use them for strong cleaning, like taking off paint or rust. I think they work well on many different surfaces and for many types of jobs.

How to Buy CleanLASER Cleaning Systems in the US

In the US, CleanLASER machines can be purchased through an official North American seller, giving customers access to local service, technical support, and reliable assistance. For more detailed product information or partnership opportunities, inquiries can be made directly through the main CleanLASER website, which connects buyers with their US sales team and provides further guidance.

Trilar Industrial Solutions LLC: US-Based Laser Machine for Cleaning Specialists

Trilar Industrial Solutions LLC stands out as a US-headquartered supplier known for reliable industrial-grade laser cleaning machines. They focus on delivering advanced, eco-friendly laser solutions for cleaning, welding, and cutting tasks in demanding environments.

High-Power Fiber Laser Cleaning Machines

Trilar offers a product range that includes 1500W, 2000W, and commercial-grade 2000W continuous fiber laser cleaning machines, all designed for heavy-duty, large-scale applications. These models are particularly effective at removing stubborn contaminants like rust, oil, and paint from a wide variety of industrial surfaces, making them well-suited for demanding cleaning tasks.

Advantages and Unique Features

- High Power & Efficiency: The machines deliver strong and efficient performance, making them suitable for extensive cleaning operations.

- Eco-Friendly Design: Trilar places emphasis on environmental safety, with technology designed to minimize chemical use and reduce environmental impact.

- User Safety: Advanced safety systems help ensure a secure operating experience for industrial teams.

Purchase and Support in the US

Trilar’s products can be purchased directly through their official US-based web store, where customers can view detailed pricing and product specifications online. US clients also benefit from localized support and consultation, with direct communication channels available for inquiries and technical assistance, ensuring a smooth buying and ownership experience.

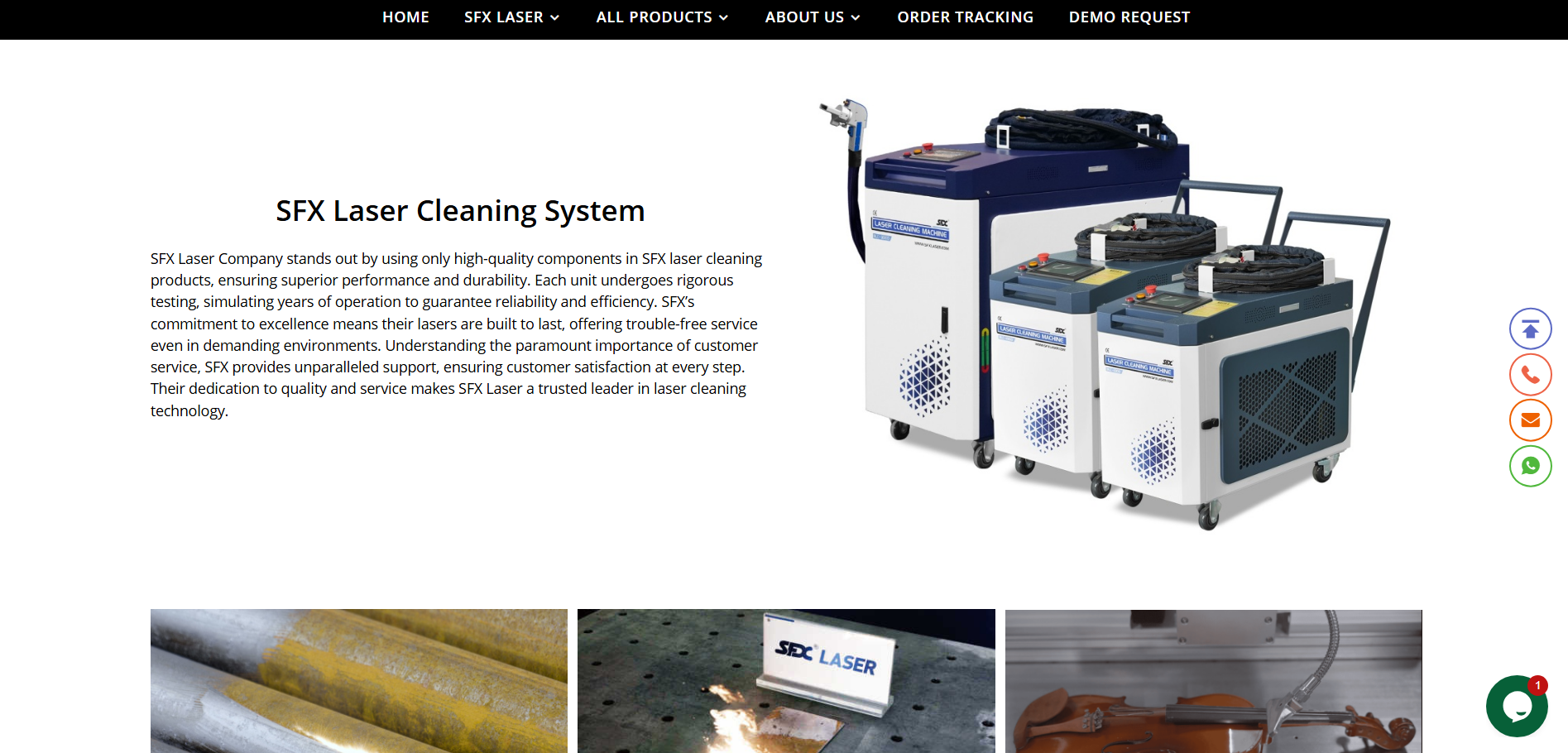

SFX Laser (Industrial Print And Laser): Local US Support & Certified Laser Machines for Cleaning

SFX Laser, also known as Luoyang SFX Industrial Technology Co., Ltd., is a reliable supplier for those looking to buy laser cleaning machines in the US. They stand out with a US-based after-sales center in New York, offering you direct, local support after purchase.

Certified Laser Cleaning Machines for US Buyers

SFX Laser offers a comprehensive range of laser cleaning machines, including continuous models from 1500W to 3000W, pulsed options ranging from 200W to 1000W, and dual-use systems that combine both cleaning and welding functions. All of their machines are FDA, CE, and ISO9001 certified, ensuring compliance with US and international safety and quality standards.

Why Choose SFX Laser?

- Local US After-Sales Service: With service and technical support located in New York, users in the US benefit from faster issue resolution and easier communication.

- Competitive Prices: SFX Laser is known for offering favorable pricing, making advanced laser cleaning technology more accessible for businesses and workshops.

- Diverse Applications: Their machines suit a wide variety of cleaning tasks—from restoring metal surfaces and removing paint to industrial degreasing and surface preparation for welding.

How to Buy SFX Laser Cleaning Machines in the US

Customers can place orders directly through SFX Laser’s US website and also benefit from convenient local support via phone or email. Products are shipped quickly from their New York service center, reducing wait times and ensuring reliable local assistance throughout the purchasing process.

LaserAX: High-Performance Industrial Laser Machine for Cleaning for the US Market

LaserAX stands out with its strong global presence and a dedicated US operation, offering industrial laser cleaning systems designed for challenging and high-demand environments.

Key LaserAX Products and Applications

LaserAX offers a wide range of solutions, from compact handheld laser cleaners to large-scale automated units designed for seamless integration into existing manufacturing lines. Their technology is tailored for industries where precision and material protection are critical, including automotive, aerospace, and heavy manufacturing.

Unique Advantages of LaserAX Laser Cleaning Equipment

- High Throughput: Engineered for fast, efficient cleaning, making them suitable for industrial workflows where speed is critical.

- Precision and Gentle Surface Treatment: Their systems are designed to remove contaminants while protecting sensitive substrates, which helps prevent damage to valuable components.

- Tailored Industrial Solutions: LaserAX offers custom engineering and consultation to match US industry standards and address specific cleaning challenges.

How to Buy LaserAX Laser Cleaners in the US

US buyers can reach LaserAX either through its dedicated US sales office or via the official website, where the company provides personalized consultations and engineering services to help clients select and implement solutions tailored to their specific applications.

How to Choose the Right Laser Machine for Cleaning for Your Needs

Selecting the ideal laser cleaner depends on your specific cleaning tasks, workspace, and desired investment. Here are key factors and expert tips to help you make the right choice:

1. Power Level: Match Wattage to the Job

- Heavy-Duty or Industrial Needs: Opt for high-power machines (1000W–2000W or more). These are effective for removing thick rust, stubborn paint, or deep contaminants on large-scale jobs. Industrial units from brands like Trilar and SFX Laser commonly range from 1500W to 3000W.

- Precision or Delicate Cleaning: For fine work—such as artifact restoration or detail cleaning—choose lower wattage models (20W–1000W). CleanLASER offers portable 20W units well-suited for sensitive surfaces.

2. Portability vs. Fixed Solutions

- Portable Laser Cleaners: If you need flexibility, opt for backpack or handheld models. These are ideal for working on-site or in spaces with limited access. Brands like CleanLASER and MaxWave Laser provide lightweight, mobile solutions.

- Stationary and Automated Systems: For high-throughput environments or repetitive cleaning tasks, consider full workstations or systems designed for integration into production lines—LaserAX and CleanLASER both offer industrial-grade setups.

3. Application Alignment: Know Your Cleaning Surface

- Material & Contaminant: Make sure the machine is built for your cleaning requirements. Some units excel at stripping paint, while others target rust or industrial oils. Review technical specs and request demo or trial service when possible (Argento Lux, for example, offers mobile services so you can test effectiveness before buying).

- Industry Use Case: If you work in aerospace, automotive, manufacturing, or public infrastructure, select a machine designed and certified for those applications.

4. Laser Type: Pulsed vs. Continuous

- Pulsed Lasers: Safer for sensitive materials and detailed surface jobs. These limit heat transfer and reduce substrate damage—ideal for restoration, electronics, or delicate metals.

- Continuous Fiber Lasers: Deliver speed and efficiency for tough, high-volume cleaning tasks on robust surfaces. Most heavy-duty industrial models are continuous, with quick contaminant removal.

5. Certification and Compliance

Ensure machines are compliant with US and international standards, such as FDA, CE, and ISO9001. Certified units are more likely to meet insurance and workplace safety requirements. SFX Laser highlights these certifications for all its models.

7. Budget Considerations

- Entry-Level: Basic industrial cleaning units often start around $5,000–$12,000.

- High-Power or Custom Machines: Expect $30,000+ for advanced or specially equipped models.

- Demo and Mobile Services: If you’re unsure, take advantage of providers like MaxWave Laser offering mobile laser cleaning. This lets you experience the equipment’s effectiveness before making a large investment.

By focusing on these points—power, portability, application match, laser technology, certifications, support, and budget—you can confidently select the best laser cleaning machine for your US-based project or business.

Frequently Asked Questions About Buying Laser Machines for Cleaning in the US

Are laser machines for Cleaning safe for all materials?

Most industrial cleaning laser machines are optimized for metals and other hard surfaces. It’s important to check if your target material—such as sensitive electronics, composites, or painted finishes—is compatible with the laser system you choose. Using the wrong power setting or laser type may cause damage, so always consult with the manufacturer or request a demo for delicate applications.

How do I maintain a laser machine for Cleaning?

Maintenance keeps your laser machine running safely and efficiently. Be sure to:

– Inspect optical lenses regularly and clean them as recommended.

– Monitor and service the cooling system according to the manufacturer’s schedule.

– Update the machine’s software to the latest version.

– Follow all manufacturer guidelines for inspection intervals, part replacements, and general care.

Do I need formal training to operate a laser cleaning system?

Basic training is strongly recommended, especially for high-power or commercial models. Most reputable suppliers—such as those featured in this guide—offer user training sessions, either onsite or virtually. Training covers operational procedures, safety protocols, and basic troubleshooting.

What is the typical delivery time for US buyers?

Delivery times for US buyers vary depending on the brand and inventory. Machines stocked in local warehouses can arrive in just a few days, while MaxWave laser cleaners ship directly from China, typically reaching customers within 7–14 days—faster than many imported or custom systems. Although MaxWave does not have a local US service center, it provides 24/7 online support to respond promptly to any customer needs. Choosing MaxWave means getting a high-performance laser cleaner along with fast delivery and around-the-clock assistance.

Summary

Choosing the right laser cleaning machine can completely transform how you handle paint, rust, oxides, and adhesives. By exploring the top suppliers and manufacturers in this guide, you can confidently select a machine that delivers efficiency, precision, and long-term value. Don’t wait—invest in a high-performance laser cleaner, elevate your operations, and contact suppliers now to get your personalized quote and start your efficient cleaning journey!