Imagine a single, compact machine that can weld, cut, and clean metal with stunning precision—without switching tools or wasting time. That’s exactly what the 3 in 1 handheld laser welding machine brings to today’s metal fabrication shops. Whether you’re running a small workshop or managing large-scale production, this innovative tool is rapidly becoming the go-to solution for professionals who demand efficiency, quality, and versatility.

In this article, we’ll explore why this powerful all-in-one system is revolutionizing metalwork and how it can help boost your productivity, reduce costs, and take your business to the next level.

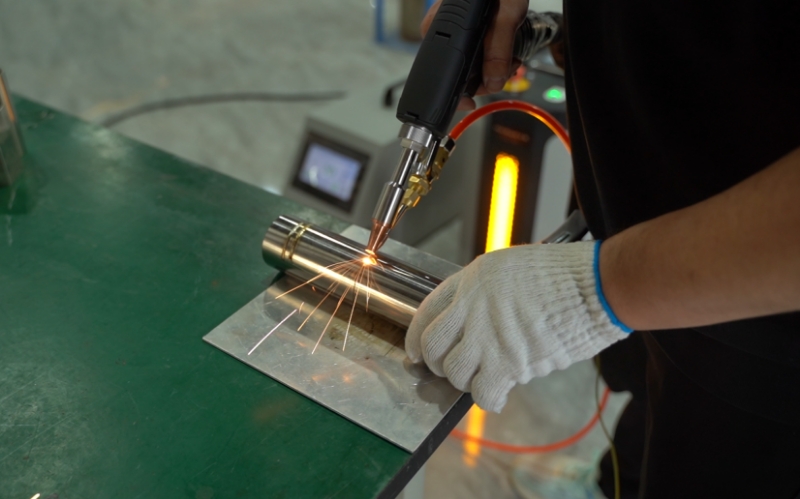

3 In 1 Handheld Laser Welding Boosts Fabrication Efficiency

I’ve noticed the 3-in-1 handheld laser welding machine really changes how metal shops work. It boosts their output in a few important ways.

Time Savings

This advanced machine processes metal at speeds up to 120mm/s (adjustable), enabling metalworkers to complete jobs significantly faster than traditional methods. Its seamless switching capability between welding, cleaning, and cutting functions eliminates tool-change delays, maximizing productivity. The intuitive smart controller further enhances efficiency by allowing operators to switch tasks instantly with near-zero downtime, creating a remarkably streamlined workflow.

Production Enhancement

Many companies have significantly increased their production speed and achieved more consistent results after adopting this three-in-one system. By combining welding, cutting, and cleaning functions into a single unit, it eliminates the need for separate tools and simplifies shop layouts. For batch production and larger jobs, using automated setups with this machine can greatly enhance output and efficiency, making it a highly practical solution for streamlined operations.

Cost Reduction

This machine has lower running costs because it doesn’t use consumables, and some models use air cooling instead of water, reducing maintenance. Its simple design and fewer moving parts make it easier and cheaper to take care of compared to traditional welders.

3 In 1 Handheld Laser Welding Machine Cuts Big Costs

From what I’ve seen, this 3-in-1 handheld laser welding machine offers great ways to cut costs in your metalworking projects.

Lower Upfront Equipment Costs

As of 2025, prices range from $3,600 to $8,200, which is great value considering it combines welding, cutting, and cleaning in one compact system. Since it includes a welding machine, gun, and wire feeder all in one, it helps shops avoid buying multiple separate machines and saves money.

Reduced Day-to-Day Operating Expenses

I like that this machine doesn’t need consumables like tips or special gases, which really cuts down running costs. It also has an oil-water separator that helps protect the internal parts, so it lasts longer with fewer repairs. Overall, it’s built for low maintenance, saving you both time and money compared to traditional machines.

Savings from Material Use and Quality

The fiber laser is highly precise, creating a smaller heat-affected zone. This helps maintain the base material’s strength and reduces the chance of faulty welds. With less waste, you save on materials and can consistently produce high-quality finished products.

With all these cost-saving aspects I’ve pointed out, I feel the 3-in-1 handheld laser welding machine is an efficient and smart financial choice for today’s metal fabrication businesses.

3-in-1 Handheld Laser Welding Machine: Superior Weld Quality & Precision

I think the 3-in-1 handheld laser welding machine stands out. It offers great weld quality and precision. In my opinion, this is a big reason it’s changing metal fabrication.

High-Quality, Accurate Welds

The focused laser beam makes a very narrow weld. The bead is usually just 0.1–0.5 mm wide. With this accuracy, I find you can join fine parts. There are no unwanted bulges or extra material. This machine creates a small heat-affected zone. I like that this helps keep the base metal’s strength and qualities. I recommend this for sensitive metals. These include stainless steel, aluminum, or titanium. It minimizes warping and discoloration. This is true even for thin or complex parts.

Speed and Consistency

Weld speeds are up to 4–5 times faster than TIG or MIG welding. Based on my experience, this speed and the laser’s accuracy create neat, high-quality seams. You can see this on small brackets and large panels alike. You can control key welding settings without effort. I find the advanced touchscreens and digital controllers make this simple. I notice the welding settings adjust with ease for materials 0.3 mm–7 mm thick. This supports many fabrication needs.

Practical Advantages in Metal Shops

The handheld weld gun is light, only 07 kg. I believe this gives precise manual control. It also means operators get less tired during long jobs. This helps workers focus on detail. I see this benefit particularly with complex assemblies.I find the real-time monitoring on the gun’s display helpful. It improves a worker’s ability to repeat welds. Operators can make tiny changes for perfect results. This works even with different metals and thicknesses.

Reduced Post-Processing

Laser welds are very precise and have minimal spatter. In my experience, this means much less cleaning and finishing is needed after welding. This makes work more efficient. I suggest you’ll find finished parts look clean and professional right from the machine.

You get perfect weld quality and exact control. There’s also very little distortion. Plus, it works with many metals. Because of these points, I believe the 3-in-1 handheld laser welder is a top solution. It meets today’s metal fabrication needs.

Skill & Training Benefits of 3-in-1 Handheld Laser Welding Machine

Easy-to-Use Design Makes Learning Simple

These 3 in 1 laser welding machines have easy controls. Think touchscreens or simple buttons. They show welding settings like power, pulse, and spot size on digital screens. I think this is great. In my view, these clear layouts help operators change settings as they work. This makes them faster and more accurate. I believe beginners make fewer mistakes than with old, tricky equipment.

Built-In Safety and Compliance

Safety is a big part of how these machines are made and how people are trained. Laser welders include:

- Embedded sensors that prevent misfiring,

- Auto-shutoff systems,

- Emergency stop buttons,

- Access control limits.

People using these machines need standard safety gear. This includes ANSI Z136.1 laser glasses and EN 388 level 4 gloves. They also need fire-resistant clothes and OSHA-approved fume extractors. I always make sure to emphasize these rules in training. This helps keep everyone at work safer.

Practical, Hands-On Certification

Leading manufacturers like MaxWave go beyond just delivering a machine—they provide full-service support. This includes free, in-depth training videos, lifetime technical assistance, and 24/7 online customer service. Whether you’re a first-time user or scaling up operations, you’ll always have expert help at your fingertips to ensure smooth, confident use for years to come.

Rapid Upskilling for a Flexible Workforce

I’ve watched new hires, after just one day of training, weld different metals like stainless steel, aluminum, and copper. They do it well, with little need for someone to watch over them. The main advantages I see are: – Little or no prior experience needed, – People gain many skills fast, – Simple certification in one workday, – I like how features like automatic wire feeders cut down on hand errors and make work more efficient.

With this flexibility, I’ve seen companies build up their talent. They can promote workers to better jobs. And they keep a very productive team with less time lost.

Game-Changing Production Power of 3-in-1 Handheld Laser Welding Machine

I believe the 3-in-1 handheld laser welding machine increases your output and makes metal fabrication more efficient. It puts laser welding, cutting, and cleaning together in one portable device. From my perspective, this single-unit design changes how work flows and sets new production benchmarks.

One Machine, Many Jobs for Smooth Work

- I see this laser machine combines three main jobs: fast laser welding, accurate laser cutting, and laser cleaning. You can handle many tasks with one system. You can switch jobs fast without needing to change tools, which I find very convenient.

- You get many welding choices: spot, seam, pulse, continuous, and repair welding modes. I recommend this for precise, small tasks or large-scale continuous welds.

- The cutting is very accurate. I’ve seen it handle thin metal sheets up to 2–3mm thick. This supports both small and mid-sized fabrication projects.

- The cleaning mode effectively removes rust, paint, resin, coatings, oil, and other contaminants. I like that this means you don’t need separate surface prep equipment.

Smart Controls for a Better User Experience

I find the advanced control systems offer settings in 9 languages. This means operators can make precise adjustments to welding, cutting, or cleaning modes right from a simple interface. Some versions include automatic wire feeders for welding. In my experience, this feature ensures the wire feeds smoothly and evenly. This reduces errors and boosts both quality and speed.

Works with Many Materials

This 3 in 1 laser welding machine processes stainless steel, carbon steel, aluminum alloys, and many other metals. I believe it’s very adaptable for different fabrication needs. One machine can handle a wide range of customer orders.

Based on my experience, with these new production abilities, I feel the 3-in-1 handheld laser welding machine truly changes the game for today’s metal fabrication shops.

Summary

After looking into the 3-in-1 handheld laser welding machine, I’m convinced it’s the future of metalworking. It’s accurate, cost-effective, easy to use, and works well in both small shops and large factories. I’ve seen how this kind of technology can transform the way people work and open up new opportunities. In my view, adopting machines like this isn’t just smart—it’s necessary to stay ahead in modern manufacturing. For more details about 3 in 1 handheld laser welding machine or to get a quote, contact us today!

Recent Comments